|

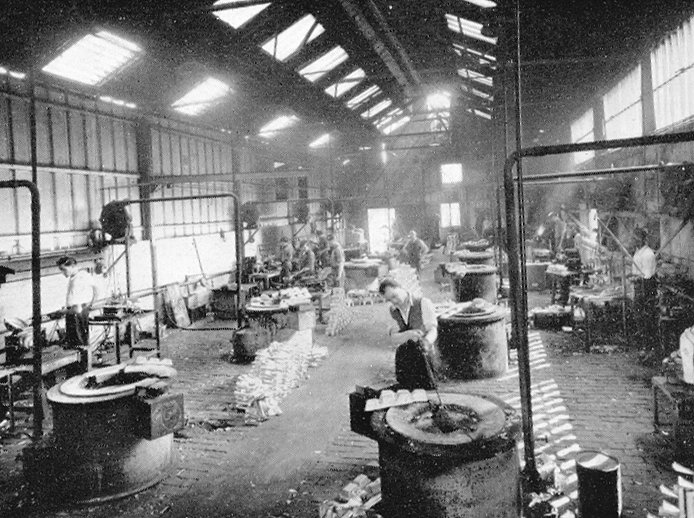

Tipton had one of the most

concentrated areas of heavy industry in the Black

Country. In the nineteenth and twentieth centuries, the

sights and sounds of industry were everywhere, along

with brightly lit orange and red skies at night.

|

|

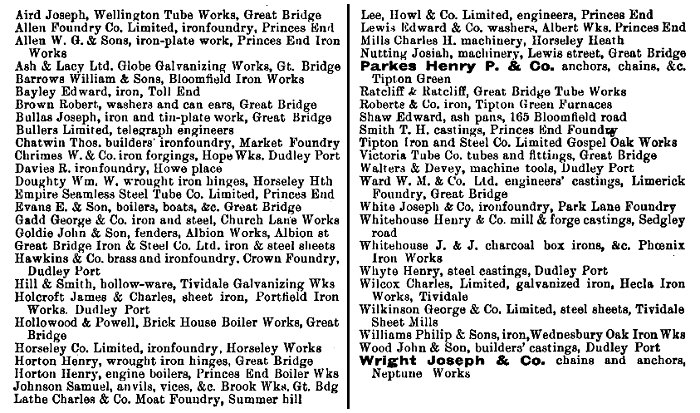

Tipton

manufacturing companies, listed in Peck's 1896

to 97 Circular Directory:

|

| Some of Tipton's Many Industries |

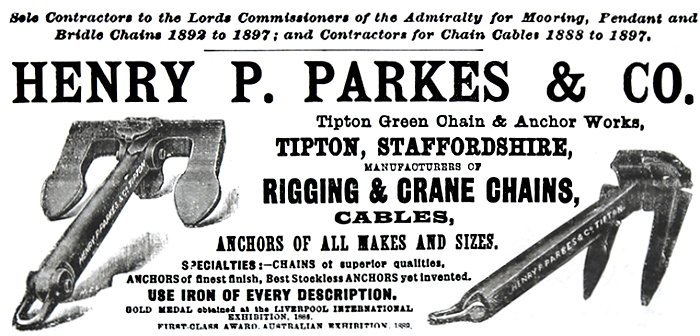

H. P. Parkes, Chains and Anchors

In about 1820 Henry Pershouse Parkes, from

Dudley, established the Tipton Green Chain and

Anchor Works. The firm’s products included

cables, chains, anchors and all kinds of

forgings. In 1851 some tests were carried out on

the company’s chains to demonstrate the tensile

strength and fibrous toughness of the iron used

in their production. The iron used on this

occasion was supplied by Summer Hill Iron Works.

Some of the chains were exhibited at the Great

Exhibition in 1851 and also at the 1855 French

Exhibition in Paris, where they won a prize

medal.

Henry Pershouse Parkes died in 1867 and appears

to have been succeeded by his son, who had the

same name. In 1867 the firm produced the largest

anchor in the world, at that time. It was built

for Brunel’s S. S. Great Eastern to the patented

design of Joseph Beterley, of Liverpool. The

anchor, which weighed eight tons was twenty six

and a half feet long and cast from iron supplied

by Bloomfield Iron Works. It was tested at

Tipton Proving House and found to be able to

stand a strain of 100 tons.

Henry Pershouse Parkes junior went into

partnership with Alexander Stewart Ross to form

Henry P. Parkes and Ross. The partnership came

to an end in 1885 and the company became Henry

P. Parkes & Company.

In 1904 the business was sold and became H. P.

Parkes and Company, under the control of N.

Hingley & Sons Limited, of Netherton. In 1944 the

company’s name was changed to Richard Sykes and

Son Limited, then in 1947 it became H. P. Parkes

& Company Limited. The business went into

liquidation in 1966.

Tipton Proving House

The Proving House was owned

by Lloyd's Public Proving House Company,

Limited, with machines that were licensed by the

Board of Trade. It

stood to the west of Bloomfield Road, alongside

the railway, between the canal and the railway,

where Bloomfield Park industrial estate is

today. It was set up following an Act of

Parliament in 1864 which instigated various

regulations.

All the work carried out

there was under the direct control of Lloyd's

Committee, London, and certificates issued were

signed by E. R. Isitt, Lloyd's Superintendent,

and were recognised by every insurance company

throughout the world. The Staffordshire Public

Chain and Anchor Testing Company also had

another test house at Netherton. The

Superintendent was Mr. S. Tregenner.

Chains, cables and anchors for seagoing vessels

had to be tested to ensure that they complied

with the various tests and specifications laid

down under the terms of various Acts of

Parliament. The Proving House also tested chains

for use in cranes and industrial applications.

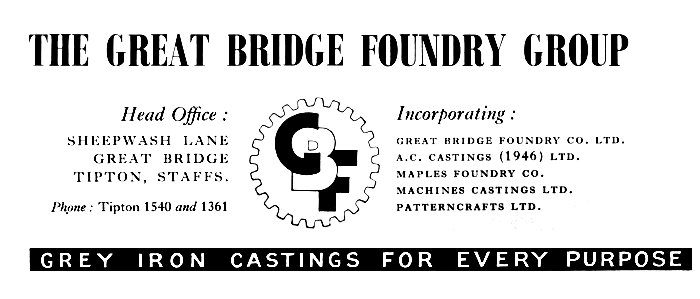

The Great Bridge Foundry Company

Limited

The Great Bridge Foundry Group of

companies started as an iron foundry, becoming a small

brass foundry. At the Sheepwash Lane works, the company

specialised in light alloys and produced about twenty

tons of sand and die castings each week along with

castings in gun metal and phosphor-bronze.

Another member of the group, Maples

Foundry produced general grey-iron castings for the

trade and for use in the its famous "Sanito" range of

sanitary fittings. Patterncrafts Limited, also a member

of the group, made patterns and dies, especially for

engineering models. A later addition to the group,

Machined Castings, Limited, supplied finished components

for many industries.

The research department developed a

machine capable of producing cores at the rate of 240

per hour, which was electronically controlled and

completely portable.

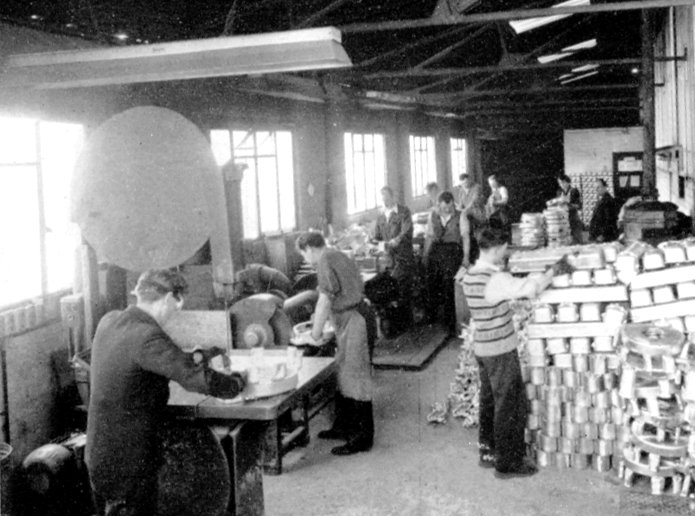

Pattern making at

Patterncrafts Limited. A member of the Great

Bridge Foundry Group.

One of the aluminium

foundry bays.

Ready to cast.

The Felting Shop at A.C.

Castings (1946) Limited.

The Gravity Die Casting

Shop at A.C. Castings (1946) Limited.

|

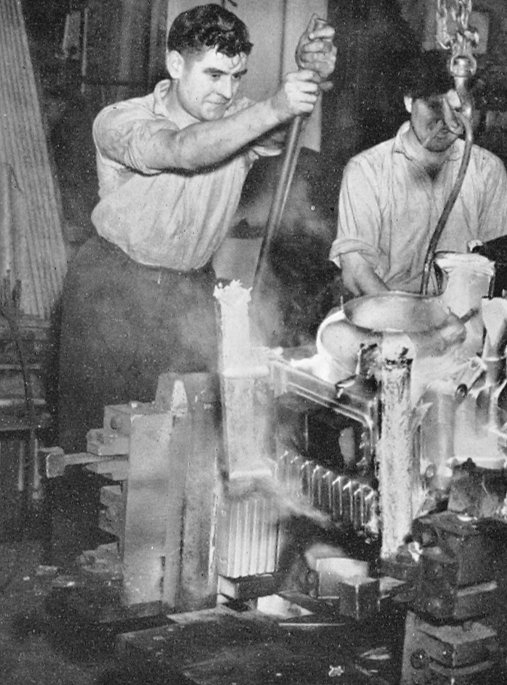

Casting a

light alloy diesel engine crankcase

at A.C. Castings (1946) Limited. |

|

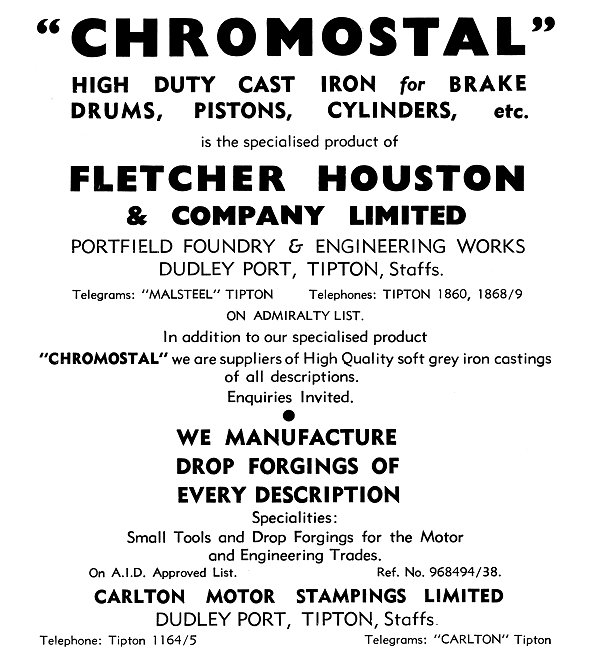

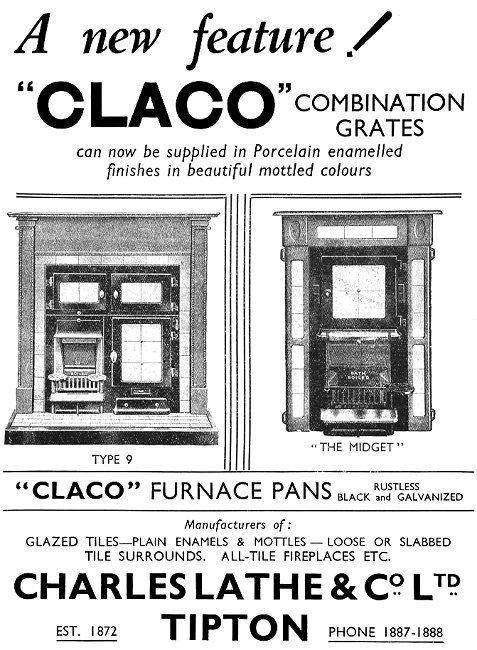

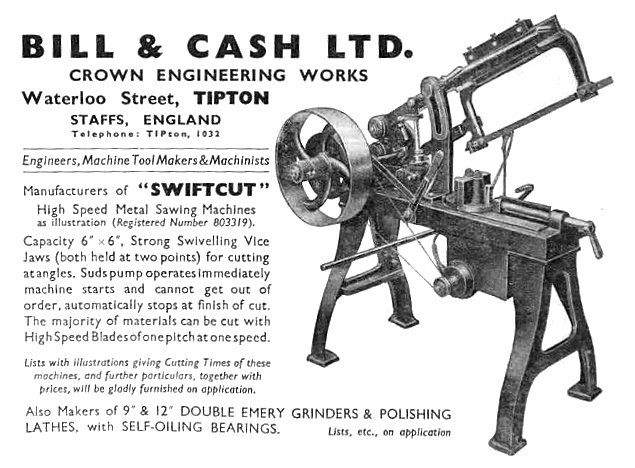

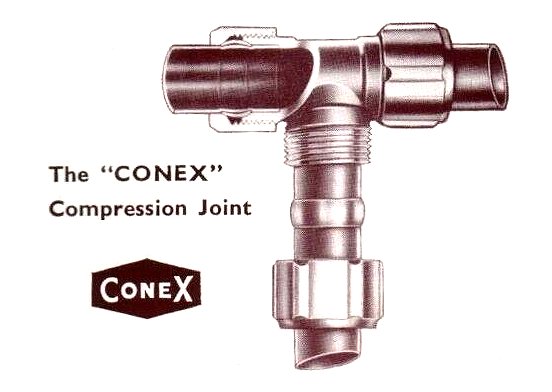

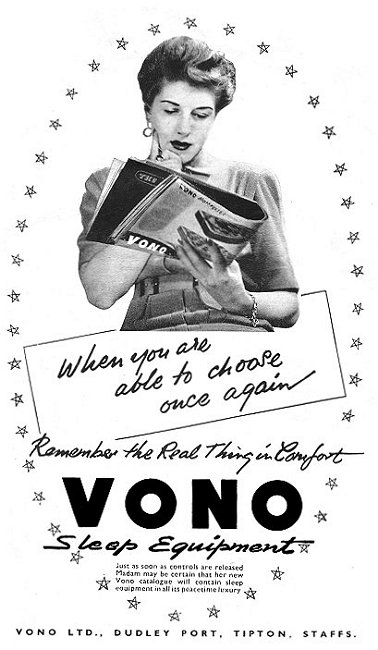

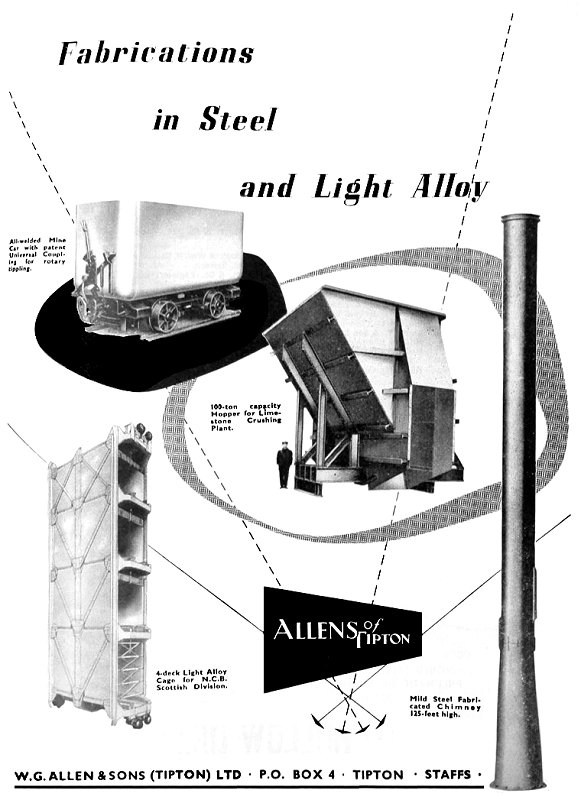

An advert from 1954.

|

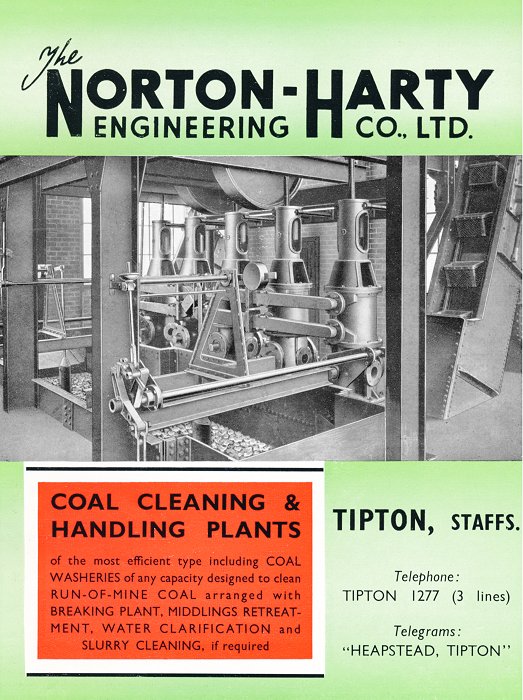

An advert from the mid

1950s. |

|

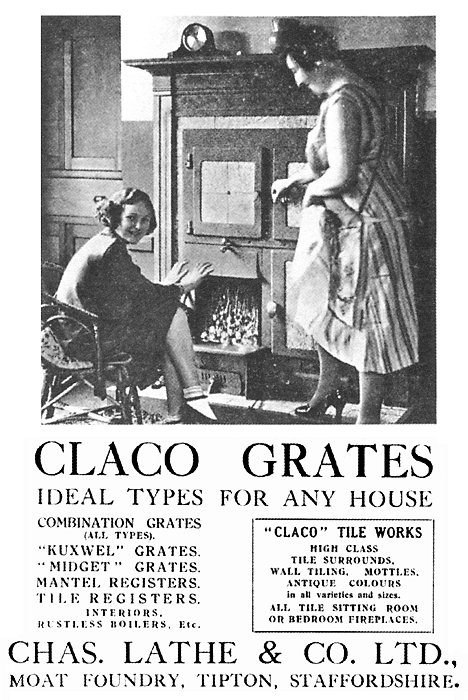

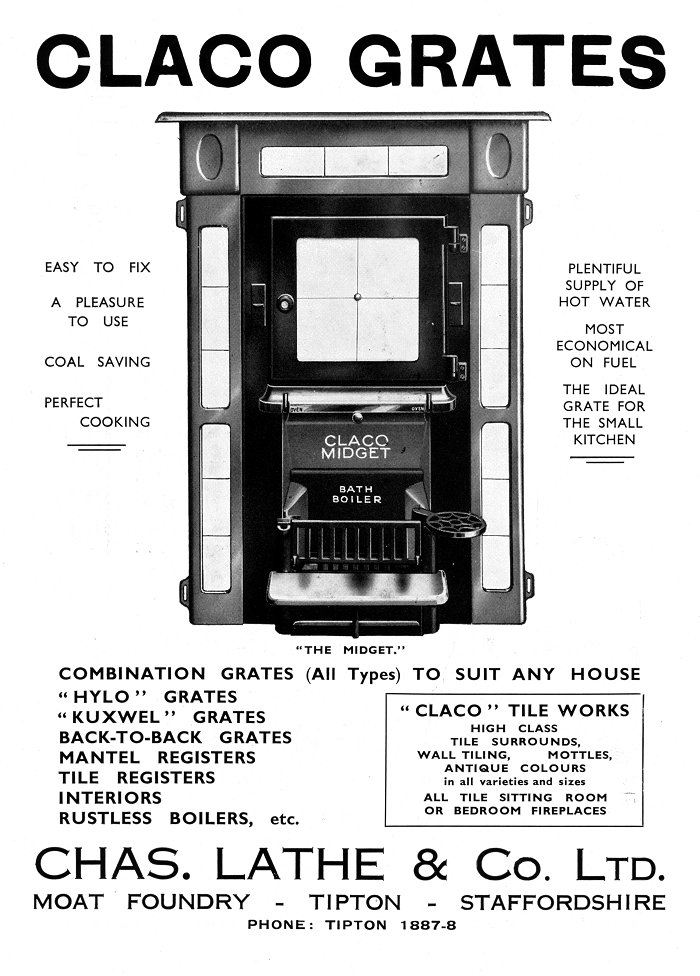

Grates and Tiles

|

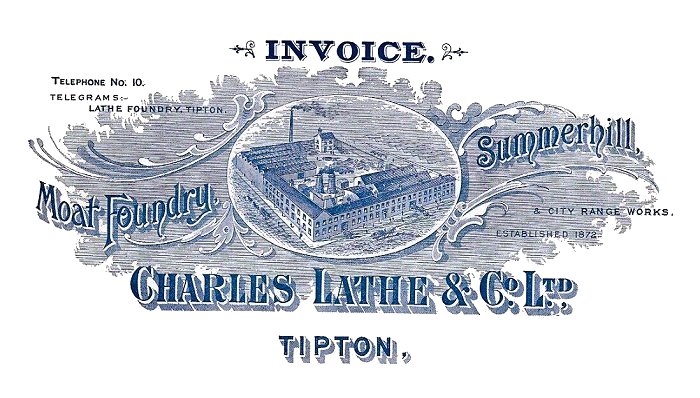

Charles Lathe & Company Limited was

founded in 1872 by Charles Lathe, J

.P. to produce a wide range of

products including glazed tiles for

fireplaces etc. and a range of tiled

fire places and grates.

The business was later run by Alfred

Lathe, J.P. and Charles E. Lathe,

grandsons of the founder.

The company's products included

solid fuel burning appliances,

continuous burning grates, convector

grates, ranges, rustless furnace

pans, castings for the building and

engineering trades and for the

railways.

A subsidiary company, Charles Lathe

& Company (Tile) Limited was founded

in 1927. The trade mark of both

companies was "Claco."

The company closed in 1969. |

An advert from 1930.

An advert from the early 1930s.

An advert from 1956.

|

|

|

Two adverts from 1947. |

|

An invoice heading

from 1914.

|

Sunbeamette Combination grates

were produced by Chatwins

Limited in Market Foundry,

Albion Street.

The

foundry stood next to the canal

where Chatwins Wharf is today.

Chatwins became part of Hale and

Hale (Tipton) Limited of Dudley

Port. |

| |

|

|

Read about Triplex

Foundry Limited |

| |

|

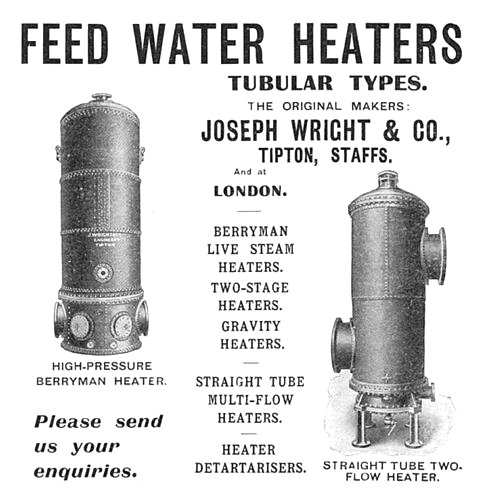

An advert from 1938.

An advert from 1909.

|

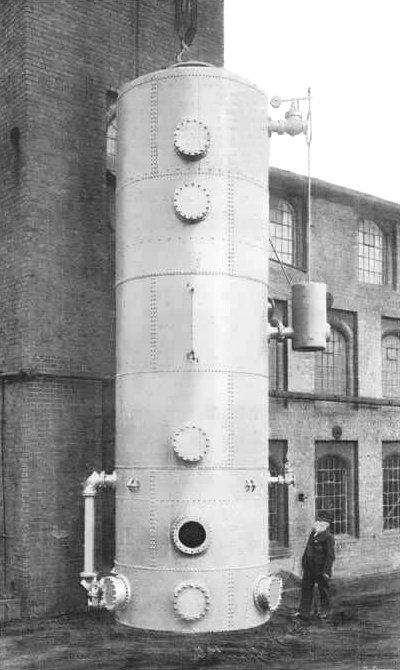

A

Joseph Wright & Company

feed water heater from 1898. |

|

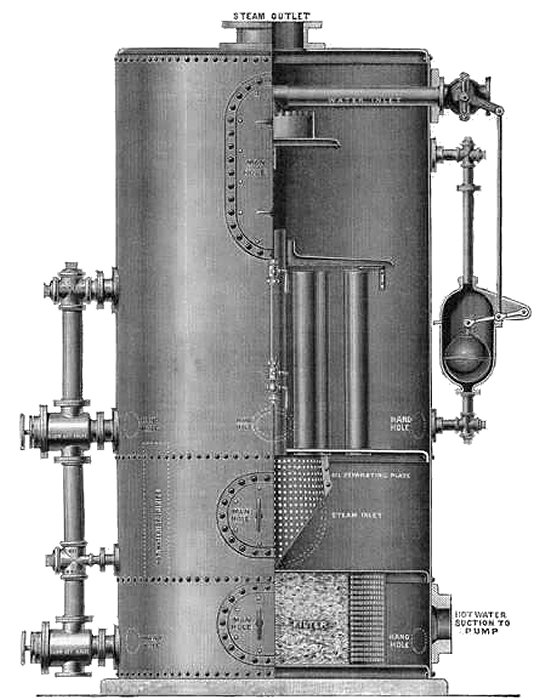

A

Joseph Wright & Company

Patent Excelsior Heater,

Filter and Grease Separator from 1895. |

A letterhead from

1947.

An advert from 1947.

The Tipton Tub and Tube Company

Limited

The Tipton Tub and Tube Company Limited was

founded in 1911 by Albert Parker and

incorporated in 1915.

Production consisted of colliery tubs, air pipes

and general engineering forgings at a site in

Brook Street, before moving to Bloomfield Road,

in 1938. A wide variety of welded and riveted

plate work was fabricated, including "Centriflovane"

grit catchers, invented by Albert Parker, and

widely used in gas works in the United Kingdom

and abroad, to remove the grit from the waste

gases from carburetted water gas plants which

would otherwise escape into the atmosphere. They

have been installed on Lancashire and other

boiler chimneys, and exhaust stacks.

The firm employed a large number of

erectors to erect both the grit

catchers and steel chimney stacks,

which were another of the company's

products. They were sold throughout

the country.

The company also specialised in the

manufacture of elevator and conveyor

buckets, ranging in weight from over

1 cwt, to less than 1 lb. Facilities

were also available to produce plate

work up to ⅜ inch thick

and forgings up to 40 lb. in weight.

The range of goods in regular

production included heavy duty and

special purpose wheelbarrows, coal

and coke chutes, tipping, drop

bottom, radial door and other

special skips, hoppers and pipe

work.

Most of the employees were with the

company for many years, the majority

having started straight from school.

Company Directors included Albert

Parker’s brother, Joseph Parker and

his nephew, John Parker.

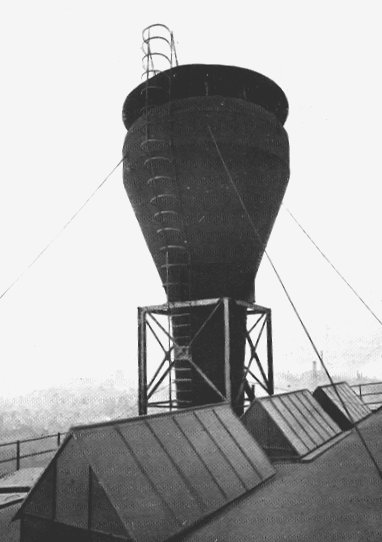

|

A

"Centriflovane" grit catcher. |

|

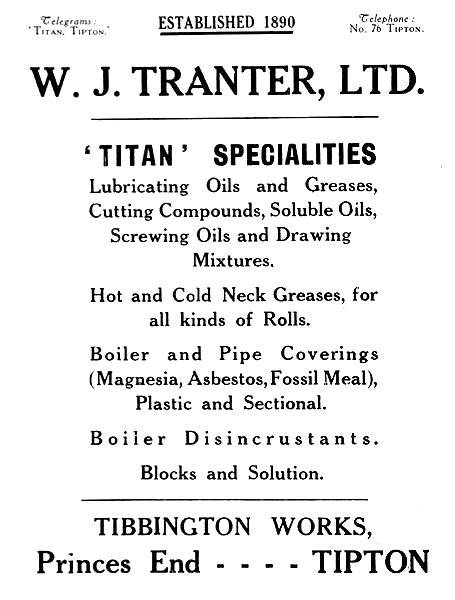

W. J. Tranter Limited

W. J. Tranter Limited, of Tibbington

Works, Princes End, founded in 1890,

produced thermal insulation for many

years. The business was very

successful and the large number of

staff carried out contracts all over

the country. Materials used included

asbestos, cork, glass silk, etc.

The firm also supplied lubricating

oils and greases, motor oils and

greases, soluble oils, drawing

mixtures, screwing oils, curriers'

oils, and sulphonated oils, etc.

which were regularly analysed and

tested in the company’s

well-equipped laboratory to ensure a

high standard of quality.

Other products included paint and

bitumen solutions, made in all

colours and grades, from the highest

quality glossy varnish paint to the

cheapest grades for rough coating.

Also gold and aluminium paints. All

materials were sold under the name

of 'Titan' Specialities and were

very well known. |

|

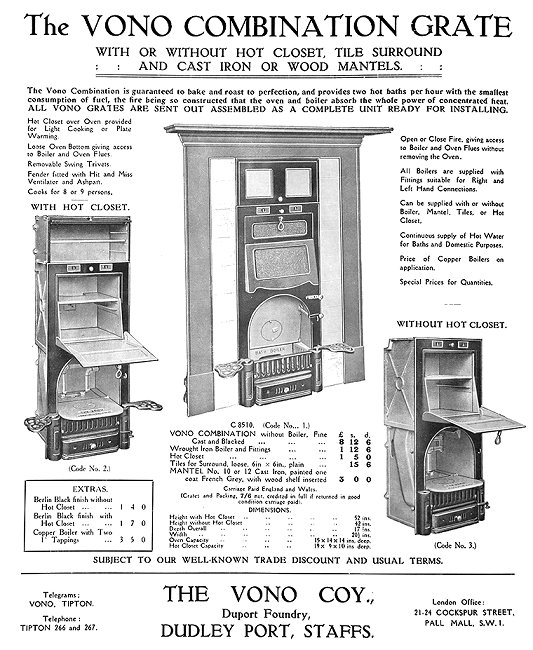

The Vono Company

|

The Vono Company, an acronym of

Vaughan Only, No Others, was founded by

Ernest

Vaughan in 1896. At one

time it was Tipton's largest employer.

His son Septimus, went into

partnership with Frederick Reeves, who

founded Revo in 1907. The

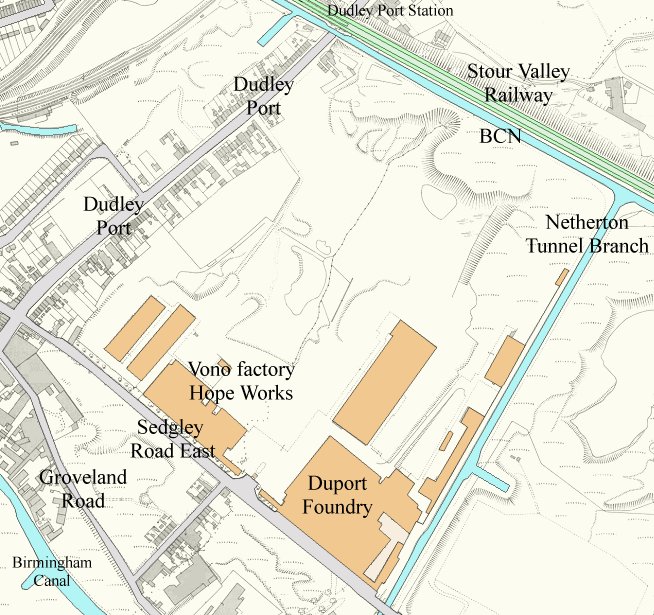

Vono factory, called Hope Works, was in

Sedgley Road East, Dudley Port, where

the Vaughan Trading Estate is today.

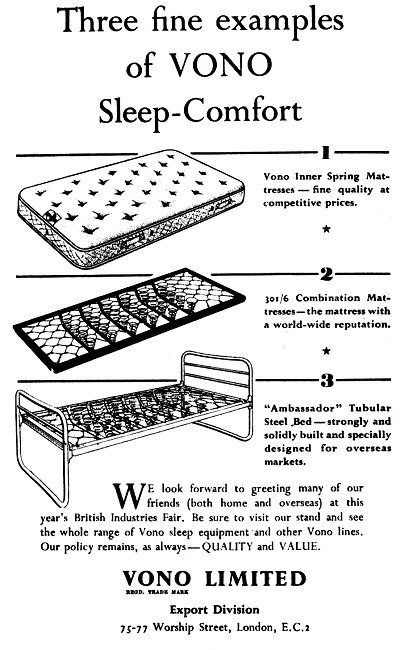

Vono specialised in the manufacture

of

mattresses

and bedstead fittings. In 1933, products included mattresses, wooden bedstead fittings and

combination and spiral spring mattresses.

Ernest Vaughan married Cecilia and

they moved into a small house on a site

that is now occupied by Burnt Tree

Island. They later moved to 'Greenroyd',

a big detached house with a large garden

in Pedmore, Stourbridge and after the

First World war, to 'Field House', Clent,

which has a Japanese style water garden

that was designed by Gertrude Jekyll in

1914.

In 1939 the firm was incorporated as a

private company.

During the Second World War, products for

the war effort included Bailey Bridges,

pontoons and ammunition. |

| In 1946 the firm became a public

company, concentrating on the production of

perfect sleep equipment; domestic equipment;

wood and metal components required for the

housing programme; engineering accessories

for the motor; aircraft; electrical; gas and

refrigeration trades; speciality castings;

plastic mouldings; fibre upholstery and

components for the railways, and the motor, aircraft

and furnishing trades. |

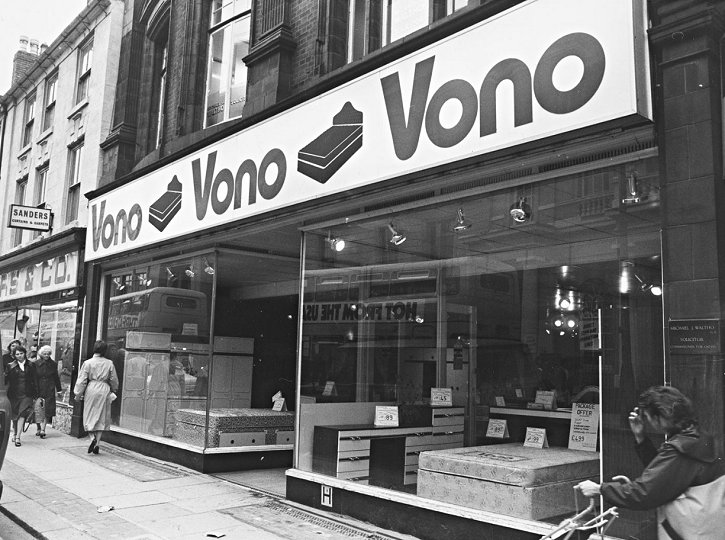

Vono's shop in Queen

Street Wolverhampton.

The site of Hope Works and

Duport Foundry.

|

The perfect sleep equipment consisted of

adjustable bedstead castors, bedstead

fittings, divans, metal camp folders,

overlays, spring interior mattresses and

wire mattresses.

In 1950, W. L. Barrows took over as Chairman

and the company name was changed to Vono

Industrial Products, which became Duport in

1956. The Duport name was derived from

Dudley Port. It was initially used as the

name for the iron foundry on the Vono site,

Duport Foundry.

Duport was an industrial holding company

that purchased a large number of

manufacturing companies, including Revo (by

an exchange of shares) in 1956. In 1967

Duport sold the goodwill, patents, and

trademarks of Revo to English Electric. The

street lighting division was sold to Tubes

Limited, who sold and developed the range

under the 'Relite' name. In 1970 Duport

acquired Slumberland Limited, which with

Vono gave it 30% of the British bed

manufacturing market.

By 1980 the steelmaking part of Duport

was in trouble and in 1981 it was purchased

by British Steel. In 1982 the bed making

part of the business was sold to Airsprung

of Trowbridge and in 1986 Duport was

acquired by Williams Holdings, an industrial

conglomerate based at Monmouth. I would

like to thank Jason Vaughan for his help

with this section. |

|

| In the 1980s, part of the Vono factory was demolished

by W Hayden & Son Limited, based in Webb

Street, Coseley. The following three photos

were taken during the demolition. They are

courtesy of Andy Hayden. |

|

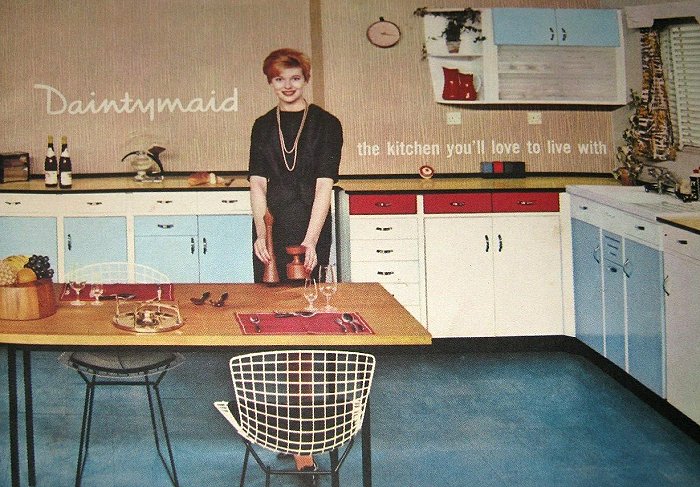

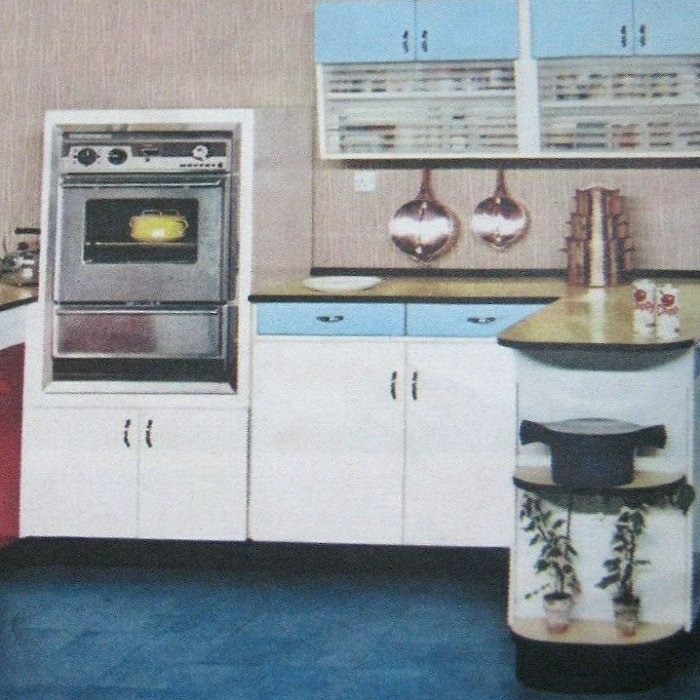

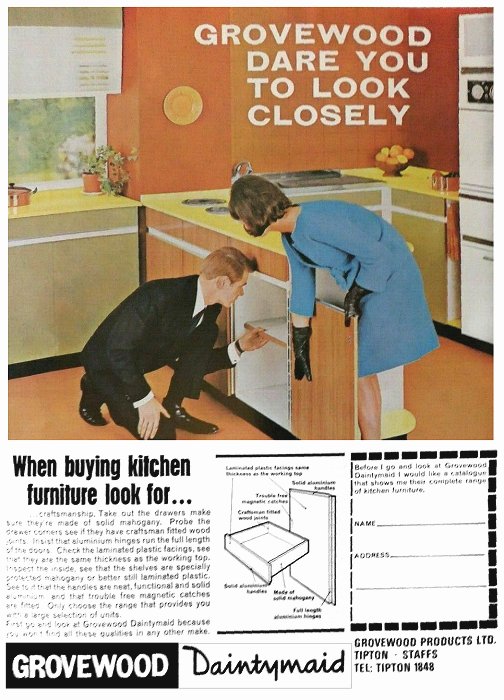

Another business that became part of

Duport was Grovewood Products Limited,

based in Dudley Port. A manufacturer of

kitchen units, fitted kitchens, chairs

and white wood furniture etc. The firm

was well known for its Daintymaid

kitchen units. |

An advert from 1954.

|

James W. Shenton

Limited has always given special attention

to breakdowns and repairs. The firm was

established in 1905 and has its own pattern

shop, machine shop and fitting shop.

Products include good quality grey iron

castings from several ounces up to four tons

in weight, including loam-moulded castings,

one-off castings, small repetition jobs for

many trades, including machine tools,

general engineering, printing machinery,

rolling mills, scrap merchants, textile

machinery, gas and electricity undertakings

and brick and tile machinery. Other products

include Crocodile shears for scrap

merchants, sand mills for foundries and all

types of special machinery to customers'

specifications along with the Norton range

of presses, cast iron bar weights, block

weights, roller weights, calibrated test

weights and machine tool castings of an

intricate nature. Long experience in rolling

mill plant enables the company to carry out

urgent repairs when necessary.

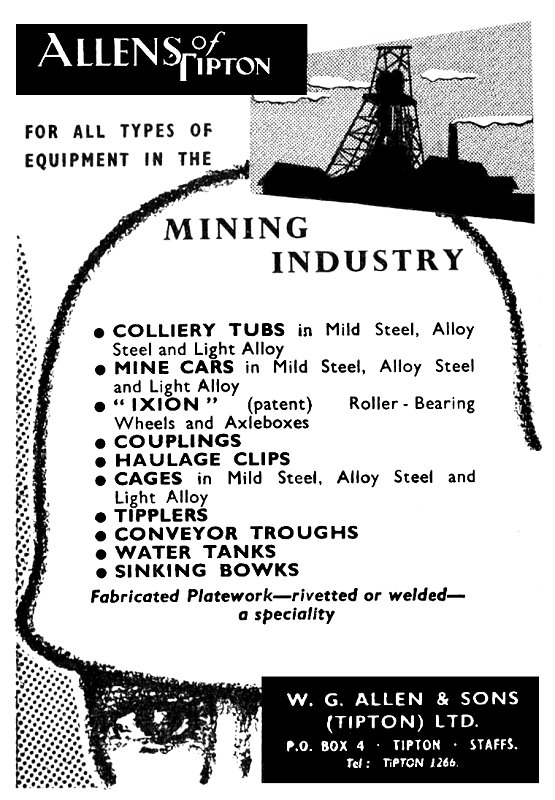

An advert from the mid

1950s. |

|

Wellington Tube Works Limited

Wellington Tube works, founded by Joseph Aird,

opened in 1872 at Great Bridge and stood between Great

Bridge Street and Brickhouse Lane, alongside

Ryder's Green locks on the Walsall canal.

An advert from 1872.

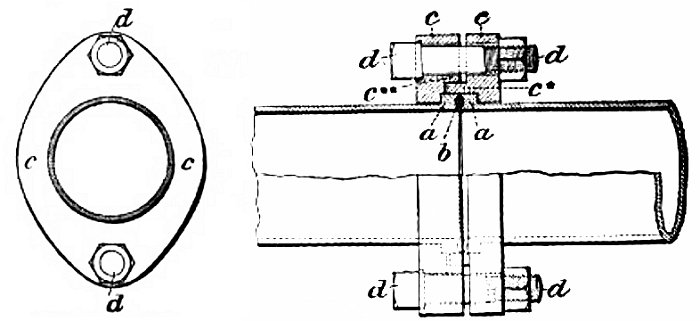

The firm specialised in large lap-welded

pipes and took out several patents in the

1890s. In 1891 Joseph Aird took out a patent

for a connector to join two lengths of tube

that were formed with a flange that was

grooved to receive a piece of asbestos or

other packing. The flanges were held

together by two clamping collars held in

position by nuts and bolts. An American

patent was obtained on 5th July, 1892.

From The Mining

Journal, 4th July, 1891.

The following article

is from 'The Engineer', 23rd April, 1897:

|

An advert

from 1938. |

In 1926 Mr. Douglas W. Turner,

Company Chairman was elected

Managing Director and in 1937

the firm exhibited a range of

products at the British Industries Fair,

including mild steel and

wrought iron tubes and fittings for

gas,

water, steam, etc. There were

also loose flanged tubes, point

rodding and

special pipework.

In 1955 a patent was taken out

for gilled

metal tubes and in 1959 a patent was

acquired for finned metal tubes.

The company formed Wellington

Tube Holdings which consisted

of: Wellington Tube

Works Limited, Wellington

Engineering Works Limited, Gibbons (Dudley)

Limited, The Stampings

Alliance Limited, F. J. Ballard and

Company Limited, and the Thermic Equipment

and Engineering Company Limited.

In 1970 Wellington Tube

Holdings sold the tube works for a

substantial amount of money to

invest in other projects.

|

A letterhead from the

1950s.

|

|

On the 11th May

1931, the Prince of Wales visited the

factory along with Lord Ednam and met

the company chairman and directors and

witnessed the production of the firm’s

wrought iron tubes.

The Prince of

Wales with the chairman and directors.

The company specialised in the

production of gas, water, steam tubes

and fittings and could test them up to

pressures of 1,500lbs per square inch.

Large stocks of the products were kept

in the warehouse.

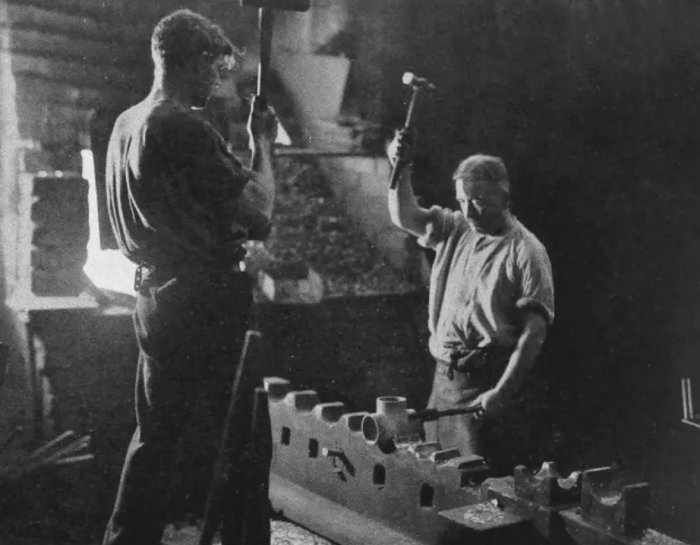

Working on pipe

fittings in the forge.

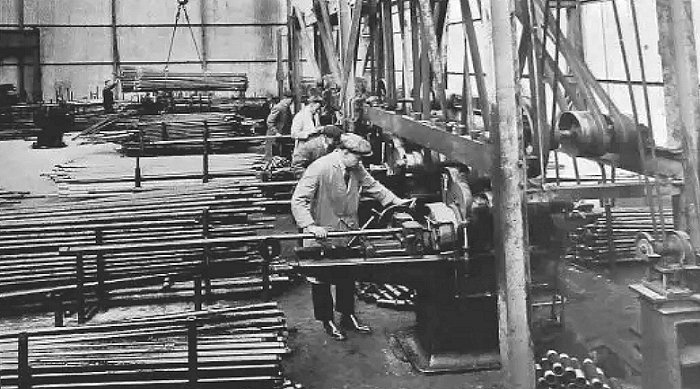

Part of the tube

screwing department.

Part of the large

tube finishing shop.

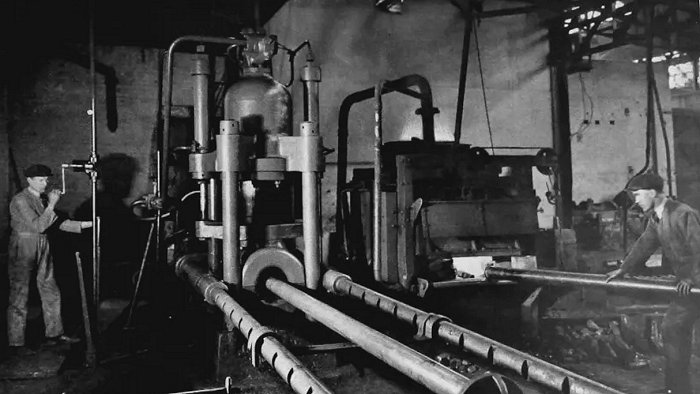

Cutting and

screwing machines and hydraulic test

pumps.

A hydraulic press. |

|

Static air-cooled heat exchangers were first

used widely where water supplies were

inadequate, polluted or non-existent.

The Heat Exchange Division of Wellington

Tube Works Limited, Great Bridge, developed

a range of air-cooled equipment which in two

basic types, could deal with any heat

exchange problem of any size.

The Wellington heat exchangers were designed

to be used worldwide, in several different

forms ranging from a single fan to multiple

fans. They were easy to install and

extremely reliable. |

A small Wellington

heat exchanger. |

|

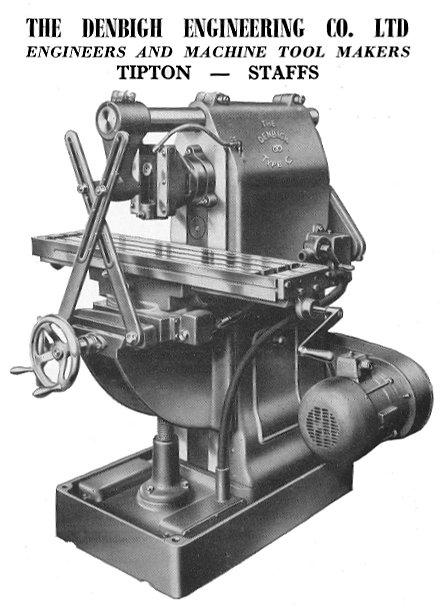

The Denbigh Engineering Company Limited

was founded in 1902 to produce the 'Denbigh'

range of machine tools, vertical drilling

machines, horizontal milling machines, power

hacksaws, and fly presses. The products

were sold through machine tool merchants and

agents throughout the world. |

A letterhead from 1937.

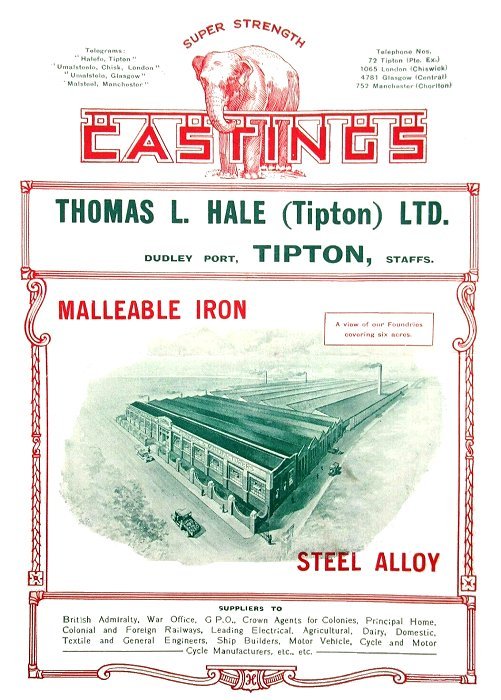

| Hale and Hale of Dudley Port, were in

business in the 1930s as Thomas L. Hale

(Tipton) Limited. The firm produced castings

in ‘blackheart’ malleable iron and steel

alloy. Hale and Hale (Tipton) Limited was

incorporated as a private limited company on

the 12th October, 1936.

Customers included the Admiralty,

the War Office, the General Post Office,

railways at home and abroad, ship builders,

electrical manufacturers, the agricultural

industry, the dairy industry, textile

machinery manufacturers, motor vehicle and

cycle manufacturers. In 1946 the firm took

out a patent for improvements to pit props.

The Chairman in the 1940s was W. Edgar

Hale.

The firm had a stand at the British

Industries Fair in 1950 and advertised the

following products: all kinds of

‘blackheart’ malleable castings, both

machined and un-machined, for railways,

electrical manufacturers, shipbuilding,

agricultural manufacturers, mining, building

and general engineering. The firm also

supplied government departments and public

bodies.

Chatwins Limited of Market Foundry,

Tipton became part of the company. |

An advert from 1957. |

An advert from 1946.

An advert from 1957.

| Hale and Hale (Tipton) Limited went into

voluntary liquidation in 1998 as can be seen

from the notice below, that appeared in the

London Gazette, on the 30th July, 1998. |

An advert from 1947.

An advert from 1947.

|

W. G. Allen

and Sons

W. G. Allen and Sons

Limited was founded by William George Allen, in

1860 to manufacture pit tubs. William George

Allen was also licensee of the Rising Sun pub in

High Street, Princess End. After his death on

the 14th July, 1882, his widow Mary Ann took

over the running of the business and the pub,

which was next to the factory.

Around 1900, the company

introduced a mild steel brewing boiler for use

by publicans who wished to brew their own beer.

The boilers were initially riveted, but later

welded. They were very successful and large

numbers were sold.

In 1908, W. G. Allen and

Sons Limited was put into voluntary liquidation

and in 1909 a private company W. G. Allen and

Sons (Tipton) Limited was formed.

Products included colliery

equipment, boilers, heating and general

engineering. The senior director, G. A. Allen

died in 1920. Two years later the Directors were

A. E. Allen and Albert Weddell, who became

Chairman. The business concentrated on colliery

engineering, iron and steel plate making, iron,

steel or wood colliery tubs, colliery air pipes

and low-pressure piping. Also portable railways

and rolling stock.

|

An advert from 1865. |

|

In 1939 the business went

public. Products at that time included pit tubs,

light railway plant, welded steel work,

industrial and domestic boilers and radiant

panels. In 1949 Albert Weddell died and was

replaced as Chairman by Arthur Dyson M.I.C.E.

An advert from November

1954.

In the 1960s the firm

became part of the W. G. Allen and Sons (Tipton)

Group and in 1961 the firm concentrated on

colliery, light railway and mechanical

engineering, welded fabrications in mild and

stainless steels and light alloys. Products

included colliery tubs, mine cars, "Ixion"

precision roller bearings and roller bearing

wheels and axles, safety couplings for mine

cars, light railway wagons, colliery air pipes

and pit cages in steel and light alloys, hydro-mech

tipplers, oil fired heaters and heatwave radiant

panels. There were 550 employees.

An advert from 1960.

An advert from 1960. |

| In 1968 the firm acquired

Perrymatics and in 1969 Allen Ygnis Boilers

Limited. The company was involved in central

heating and engineering, but Allens of Tipton

made a loss. In 1981 there was a great reduction

in the demand for oil and gas fired boilers and

air heaters and in 1984 the company went into

liquidation. Most of the assets and the

subsidiaries were acquired by Stone

International in 1985. |

|

G. H. Whitehouse & Son

In 1902 Mr. G. H. Whitehouse entered into

partnership with John Tudor and Herbert Onions

to start in business as G. H. Whitehouse &

Company, at Great Bridge Engineering Works,

reconditioning steam plant. The business

soon specialised in contract machining and

machine tool work.

During World War One the firm produced

munitions including 4.5 inch shells.

After the war, trading conditions were very

difficult. Mr. Whitehouse had to run the

business alone because his two partners had

died. The firm then began producing equipment

for the Royal National Lifeboat Institution

including lifeboat launching keelways.

The firm also developed and patented an

improved gas control unit that was sold under

the name 'Sentinel'.

|

| In 1937 Mr. G. H. Whitehouse was killed in

an air crash whilst on business on the

continent. Luckily his son, Mr. H. G. Whitehouse

was able to take over, having just returned from

the USA. In 1939 at the outbreak of war, the

company became one of the leading companies

specialising in the reconditioning of machine

tools and also produced large quantities of

heavy brake drums for aircraft. The firm also

designed and patented a universal joint which

sold in large quantities. After 1945 the firm

specialised in the design and manufacture of

special purpose machinery and the manufacture of

racing plates. |

|

John

Cashmore Limited

A once well-known Great

Bridge company was John Cashmore Limited, iron

and steel stockholders, dealers in new and used

machine tools, with a breakers yard, where a

large number of British Railways’ steam

locomotives were broken-up for scrap at the end

of the steam era.

The business was located

off Bagnall Street, Golds Hill, alongside the

Tame Valley Canal and the section of the South

Staffs Railway line that ran between Wednesbury

and Dudley. |

|

The firm also had a similar

factory in Newport South Wales, alongside the

River Usk, where many ships and steam

locomotives were scrapped.

In October 1926 Cashmores

acquired and demolished the Bromley Ironworks at

Brierley Hill; and in November of that year

acquired and demolished the Bromley Ironworks.

John Cashmore died in 1932

at the age of 92. The family continued to run

the company which became quite successful. In

1939 the Directors were: Frederick W. Cashmore,

Ernest E. Cashmore, Harold V. Cashmore, John

Venables, Arthur Smith and John E. Cashmore.

John Venables, soon became Managing Director,

followed by his son Stuart.

The firm specialised in

salvaging scrap metal from demolished factories

and foundries, and also scrapping old ships at

Newport, and old steam locomotives at Great

Bridge and Newport.

After the Second World War,

Cashmores installed machines to cut coil strip

steel into sheets for manufacturers and began

stocking stainless steel. |

An advert from 1945. |

|

The company's stock of

machine tools included:

Air Compressors

Bandsawing Machines

Bending and Straightening Rolls

Billett Breaking Machines

Horiz. & Vertical Boring Machines

Capstan Lathes

Cold Saw Machines

Drilling Machines

Grinding Machines

Hammers

Hydraulic Plant

Lathes

Milling Machines

Planing Machines

Screwing Machines

Shaping Machines

Slotting Machines

Turret Lathes

Thread Milling Machines |

|

An advert from 1950. |

|

The business greatly

expanded thanks to the efforts of Norman

Cashmore, who died in June 2009 at the age of

96.

He had been born in Tipton

in 1913 and won a scholarship to Queen Mary’s

School in Walsall. He joined the family business

in 1972.

The company was floated on

the stock market in 1959 and by the early 1970s

was one of the country’s largest and most

profitable steel stockholders, with warehouses

throughout the country.

The shareholders agreed to

sell the business to Glynwed International, the

West Midlands-based conglomerate, in 1972.

Mr. Cashmore served on the

Glynwed board before retiring. |

An advert from 1952. |

|

An advert from 1929. |

An advert from 1958. |

An advert from 1958.

A letterhead from the early 1930s.

An advert from 1958.

An advert from 1958.

An advert from 1958.

An advert from 1952.

|

The Roman Mosaic factory was

once a familiar sight in Bloomfield Road. The

business moved there from its previous premises

at Burnt Tree Island, Dudley, in 1988.

The factory was well known for

importing and distributing ceramic tiles and

glass mosaics and was also well known for its

large Roman-themed murals.

Unfortunately the business

closed in 2007 and remained derelict for many

years. During this time it was broken into many

times and anything that was easily removable was

stolen.

The factory was demolished and

new houses have been built on the site. |

|

Joseph Batson &

Company Limited, Dudley Road, Tipton, on the

corner of Castle Street and alongside the canal.

The firm were Oil refiners

and grease manufacturers.

In 2003 the business

was acquired by

H & R ChemPharm (UK) Limited.

It is now one of the few remaining Tipton

factories that are alongside the canal. |

|

|

|

|

|

Return to

Victoria Park |

Return to

the

beginning |

Proceed to

Growing Town |

|