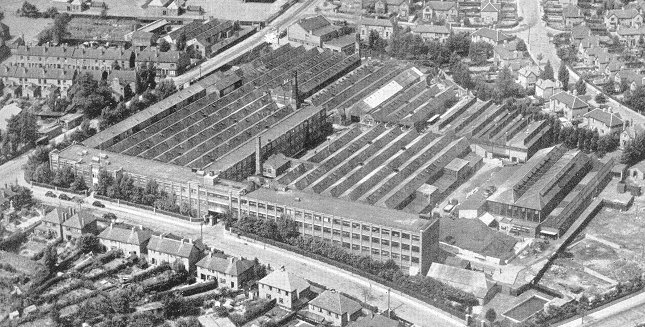

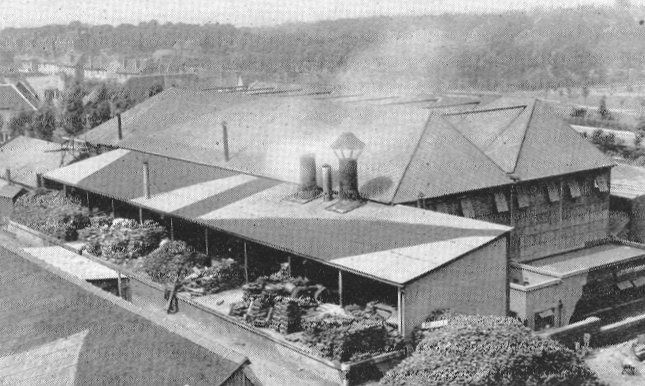

| By the 1940s, Lincoln Works covered over seven acres,

and was the country's largest factory producing

electrical accessories. The company was also one of the

country's largest consumers of porcelain for electrical

purposes.

By 1946 the company employed around 1,800 people, who

were carefully selected for intelligence and initiative.

The firm had its own research laboratories, and

manufactured all of the component parts for the Crabtree

products, except the porcelain, which came from the

potteries at Stoke-on-Trent.. |

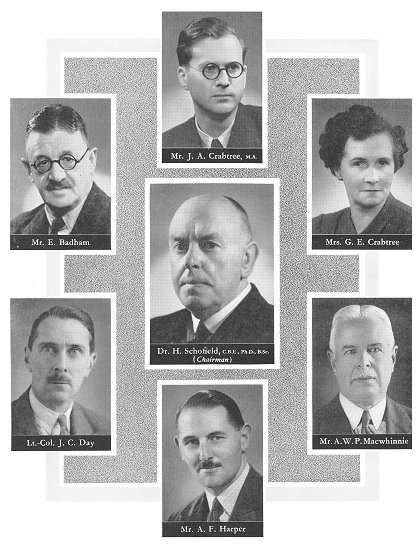

The company's directors in 1947. |

|

Lincoln Works in 1946. |

|

A map of the area today, showing

the site of Lincoln Works. |

|

The Duke of Kent at the factory in

December 1940. |

|

The entrance to the offices. |

|

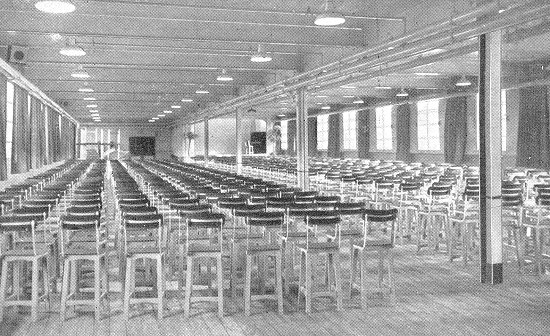

The canteen, laid-out for an

evening concert. |

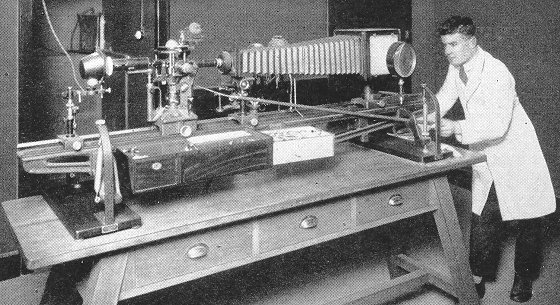

| The Laboratories All the raw

materials purchased by the company were tested and examined

before use in the factory. Samples were taken for chemical

analysis, microscopic examination, and physical testing. |

|

The chemical laboratory. |

| During the manufacturing process, further tests were

carried out to ensure that all components would perform

correctly in use. Pressed items were examined for uniformity

of hardness and thickness, and if annealing was necessary,

the most suitable temperature for the annealing ovens would

be chosen. Tests were carried out on every metal part

that had to be heat-treated, to make sure that no

deterioration took place. |

|

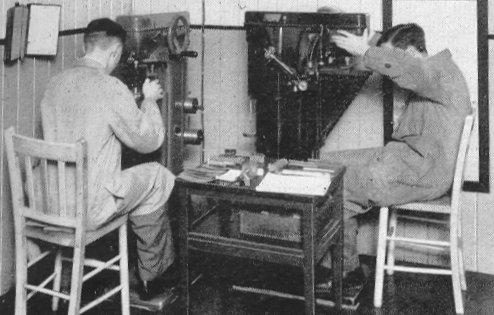

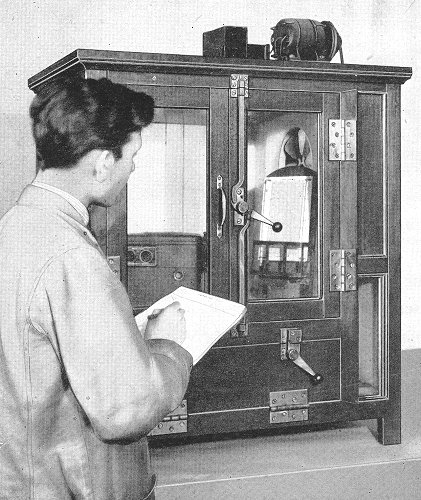

Microscopic examination of grain

structures. |

| A close eye was kept on the raw materials that went into

the cupola furnaces in the foundry, to make sure that cast iron

was produced to

the correct specification, and to determine the optimum

casting temperature. The laboratories also ensured that the

paint and enamels used in the factory were of the highest

quality.

Tests were carried out on their resistance to corrosion

and abrasion, and also to the organic acids that are present

in certain foodstuffs, which could damage the finish of cooker control units.

The iron cases that were used on some of the switchgear

cases were tested for their resistance to corrosion in an

open area on the roof, where they were exposed to the elements

for periods of time. |

High frequency pre-heating equipment. |

|

Testing metal specimens for

hardness. |

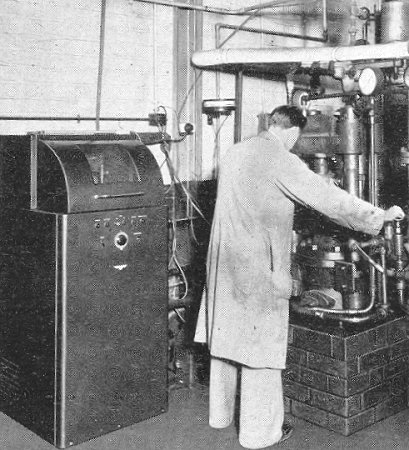

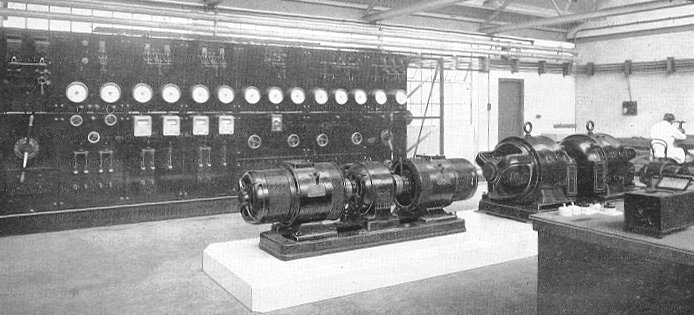

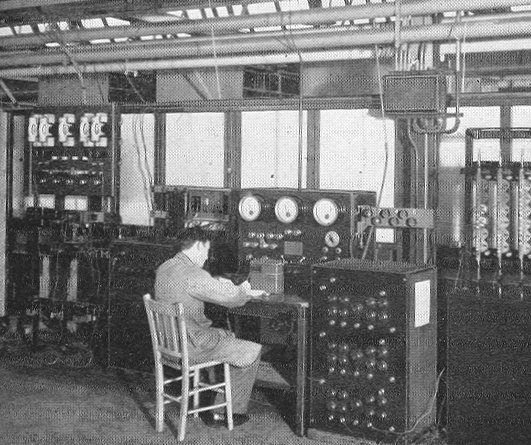

| The Electrical Laboratory The

laboratory had electrical plant to produce AC and DC

voltages for a wide range of tests. The AC supply came from

the mains supply, which was also used for a motor-generator

set that provided the DC supply. There were also two banks

of rechargeable batteries, each providing a 250 volt DC

supply. The batteries were designed to withstand large

short-circuit currents. |

|

The generating plant and

switchboard. |

| A corner of the electrical

laboratory, showing some of the test equipment. |

|

|

Carrying out a humidity test. |

The laboratory had an extensive range of meters,

oscillographs, and resistance bridges. All incoming

materials were examined for their electrical characteristics

to ensure that they were suitable for purpose.

Finished products were also inspected and thoroughly

tested to make sure that they operated within their

specification. Overload characteristics were also tested.

Efforts were continually made to improve existing

products, both in the materials used, and construction. |

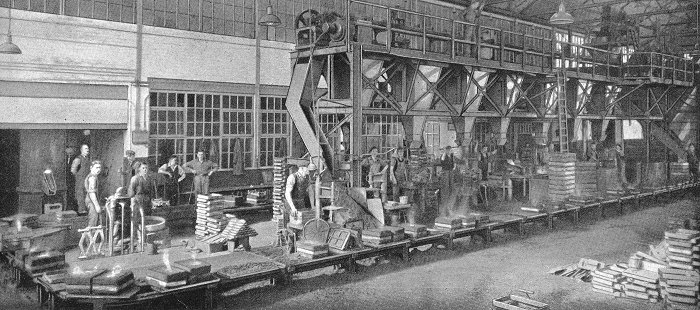

| The Foundry Lincoln Works'

foundry used the latest and most up-to-date machinery

including hydraulic and pneumatic moulding machines that

were fed mechanically by hoppers. They were encircled by a

slowly moving conveyor. |

|

The foundry, showing piles of pig

iron. |

|

The production plant, and the

conveyor, loaded with moulds. |

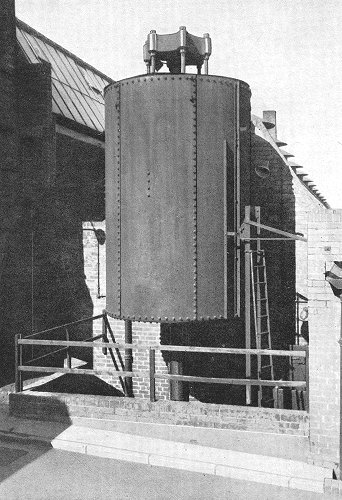

| The foundry had siphon type cupolas that provided

molten iron for most of each working day. |

| The conveyor carried the moulds from the moulding

machines to the pouring point, then on to the knock-out

point, a journey of about fifteen minutes.

At the knock-out point the casting was removed from the

mould, which was then broken up. The sand fell through an

open grid in the floor to an underground conveyor which

carried it to an area where it was screened, cooled, and

milled.

Any remaining scrap iron was removed by a

magnetic field. Flight conveyors then transported the

refined sand to the hoppers for re-use. |

Pouring molten iron from one of the

cupolas. |

|

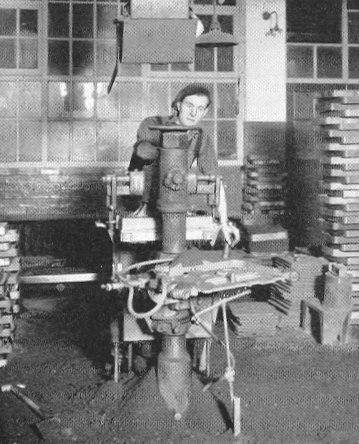

A moulding machine in operation. |

The castings were sand-blasted to remove any remaining

sand, and to show-up any surface defects. They were then

transported to the grinding and bobbing machines for

cleaning-up, before going to the mechanical enamelling plant,

to be given a heavy stove-enamelled finish.

Some hand moulding was still employed for castings that

were unsuitable for mechanical production. For this work, a

few highly skilled moulders worked in the traditional way,

carrying out floor and stump moulding.

The company had its own patternmaking section where

patterns were produced in wood, white metal, aluminium, and

gunmetal.

The cast-iron components were carefully monitored by a

metallurgical chemist, who ensured that the highest standards

of quality and accuracy were maintained. |

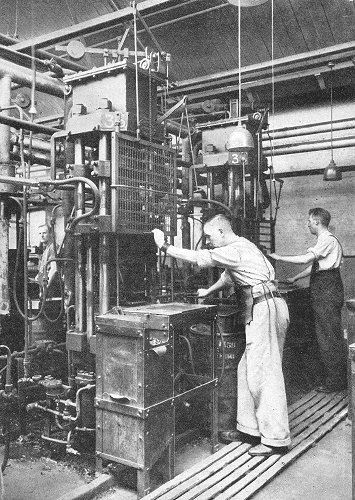

| Moulding Department The moulded

cases and covers used in Crabtree products were produced in

the factory's moulding department, on hydraulically-operated presses.

Hydraulic pressure was supplied by an eighty ton hydraulic

ram, mounted high on the building. Components were moulded

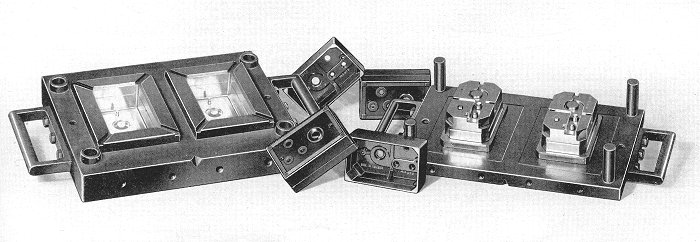

in 'Jacelite' (phenol formaldehyde), and P.V.C. The dies for

the mouldings were produced in the toolroom to a very high

standard. The quality of the finished product depended

entirely on the quality of the die. The presses had

steam-heated platens, which were maintained at a precise

temperature.

The high quality finish achieved relied upon the close

cooperation of many members of staff, including the artist,

the draughtsman, the research chemist, the toolmaker, and

the plastics production engineer. At every stage of

production, the process was carefully monitored.

|

|

|

|

|

The eighty ton hydraulic ram. |

|

Some of the hydraulic presses. |

|

|

The steel dies for a switch socket

outlet cover, together with some of the mouldings. |

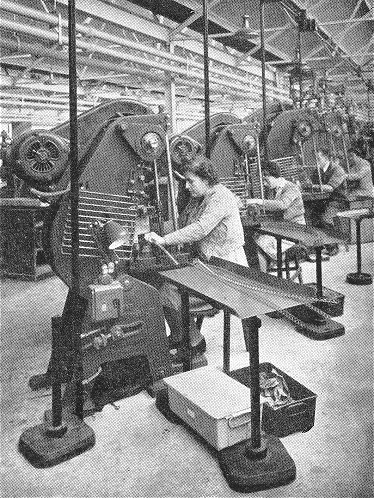

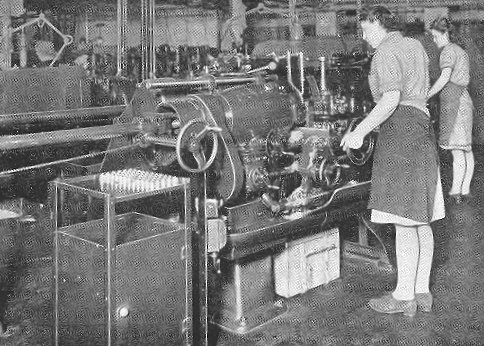

| Machines Used in Production The

production process was automated as far as possible. In the

late 1940s the company always used machines made in the UK.

Millions of small component parts were produced each week

for the wide range of Crabtree products.

Many high speed machines were used, such as . drilling

machines that ran at speeds from 5,000 to 10,000

revolutions per minute.

High speed machines were used in the automatic turning

department where millions of small screws and terminals etc.

were made.

Some of the smaller components such as switch contacts

went through a sequence of delicate bending operations which

had to be carried out by hand, using the old-fashioned fly

press.

The firm's power presses were equipped with multiple

tools and could produce between three to four hundred parts

a minute. |

Stamping blanks from metal strip. |

|

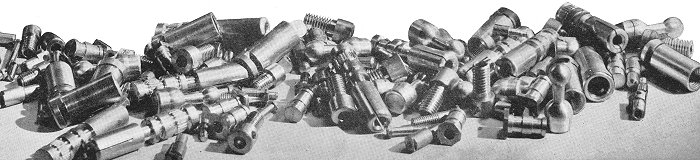

A few of the large number of

turned brass parts used in the company's products. |

|

Part of the power drilling bay. |

| Machining components to close

tolerances. |

|

|

Adjusting a high speed automatic

machine. |

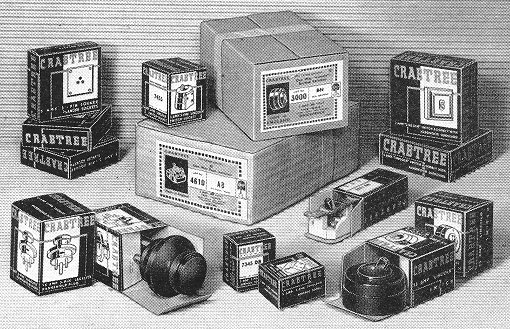

| Packaging The company moved away

from multiple cartons to separate cartons for each product,

made of strong cardboard, printed in a distinctive red and

black design. The individual cartons were placed in strong

outer boxes made of corrugated cardboard, holding six or

twelve of the cartons.

This technique eliminated breakages during transit, and

allowed the individual products to be easily identified. |

Crabtree cartons. |

|

A corner of one of the packaging

rooms. |

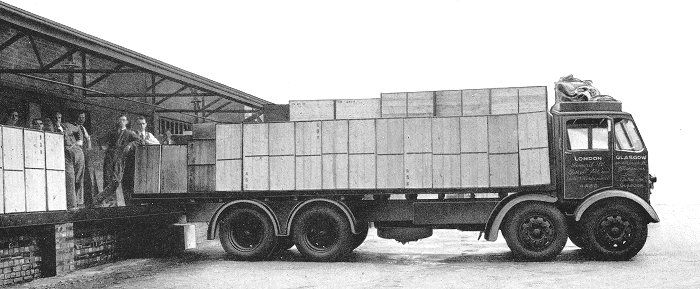

The company's ironclad switchgear, and the larger

automatic control units were packed individually in

corrugated cardboard cartons.

The cartons were transferred from the stock bins and

placed in conveyor trucks. After checking against the

customer's order, they were placed on a roller-conveyor belt

to be carried to the packing room, where they were placed in

suitable boxes or cases.

The completed cases were transferred from the packing

room to one of the company's lorries or trucks for delivery. |

|

Part of an export order being

loaded onto one of the company's lorries. |

| World-Wide Distribution Crabtree

products were sold throughout much of the world. The company

had agencies in Argentina, Australia, Barbados, Belgium,

Brazil, British Columbia, Burma, Ceylon, China, Columbia,

Cyprus, Egypt, Ireland, Ethiopia, Faroes, Fiji, Finland,

France, Gold Coast, Greece, Iceland, India, Iraq, Italy,

Kenya, Malaya, Malta, Mauritius, Mexico, New Zealand,

Norway, Palestine, Peru, Portugal, Seychelles, Siam, South

Africa, Sudan, Sweden, Switzerland, Tanganyika, Trinidad,

Turkey, Uruguay, and Zanzibar.

There were also distributors in Afghanistan, Algeria,

Chile, Costa Rica, Denmark, Hong Kong, Indonesia, Libya,

Madeira, Morocco, Tangier, and Uganda. |

|

|

| View some of the company's

many products from the late 1940s |

|

| |

|

|

Return to

the

previous page |

|