|

The Leather

Industry

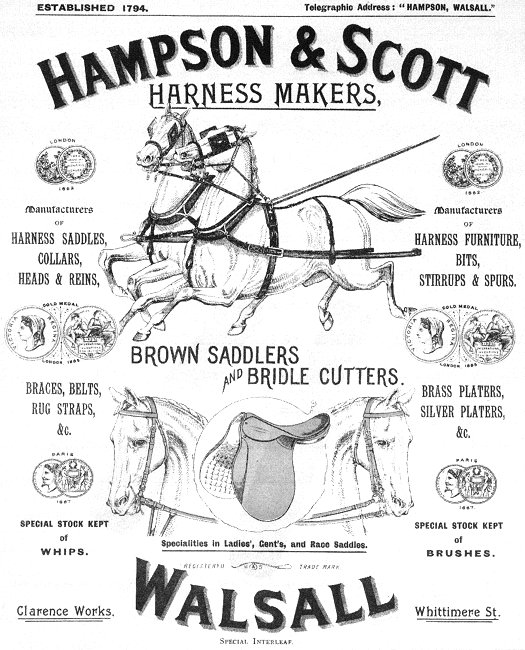

An advert from 1851.

Most leather work was originally

carried out in small workshops, usually by men, often in a

yard behind a house. Most businesses were small, employing

between one and three people. All that was required to carry

out the work was a few inexpensive hand tools such as

hammers, knives, pincers, and a pricking iron. Curriers used

a two handled knife to shave the leather to the required

thickness. Most of the tools were produced in the town so

that Walsall’s leather trade became almost self-sufficient.

By the middle of the 19th century,

leather factories had appeared, which employed men, women

and children. Within twenty years large numbers of women

worked in the industry. In the late 1860s around sixty

percent of the workforce in bridle and harness making were

women, and around thirty percent of saddlery workers were

women. The development of the sewing machine in the 1850s

greatly changed manufacturing. It led to larger workshops,

and increased production.

In the 19th century the industry

thrived because of the expanding number of working horses in

Britain, and an increasing demand for saddlery and harnesses

from abroad, particularly from the USA, India, Australia,

New Zealand, and South America. The local factories

benefited greatly by the coming of the railways, which

enabled products to be quickly and efficiently sent to

destinations all over the country, including sea ports where

goods could be loaded onto ships for export.

William White lists the following

leather goods manufacturers in his Staffordshire directory

of 1851:

|

| 19 |

|

Bridle cutters |

| 57 |

|

Saddle, harness, and collar

manufacturers |

| 7 |

|

Whip thong makers |

| 14 |

|

Curriers and leather sellers |

| |

|

|

| |

|

Allied industries |

| 19 |

|

Stirrup manufacturers |

| 4 |

|

Spur rowel makers |

| 19 |

|

Spur manufacturers |

| 6 |

|

Saddle tree makers |

| 3 |

|

Saddlers’ tool makers |

| 27 |

|

Saddlers’ ironmongers |

| 2 |

|

Saddle nail makers |

| 12 |

|

Buckle tongue makers |

| 38 |

|

Buckle makers |

| 47 |

|

Bit makers |

| 8 |

|

Hame and harness iron makers |

|

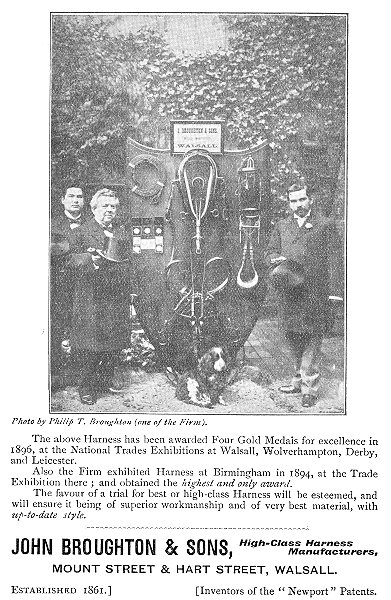

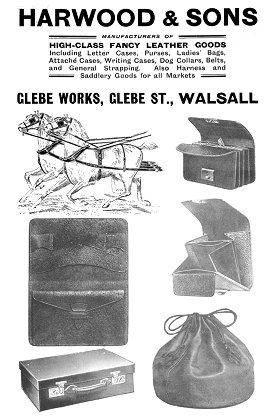

An advert from 1865.

|

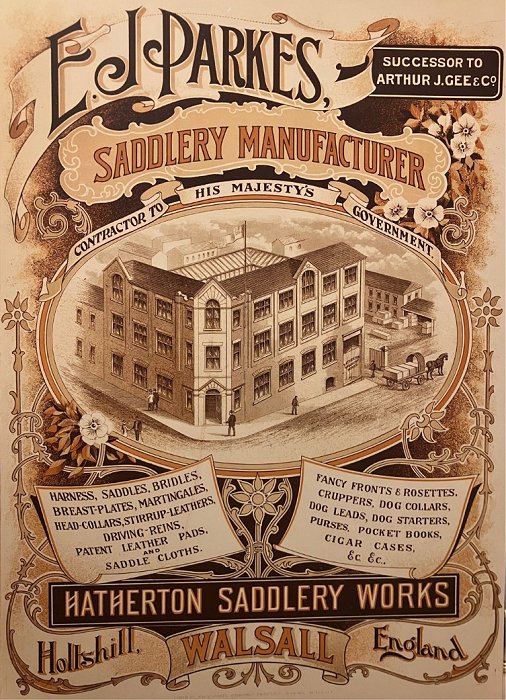

An advert from 1899. |

After 1870 the leather manufacturers

suffered because of competition from Germany, and falling

markets in Europe.

Another threat was the introduction of

the motor car. The innovative industry responded by turning

to the production of bicycle saddles, and upholstery, and

fancy leatherwork for motor cars.

Some of the old saddle

makers and harness makers began to produce sports equipment

and travel goods. Other manufacturers began to produce bags,

purses, cigar cases, dog collars, and fancy leather, often

for export.

By 1910 there were eight tanneries and twenty

seven curriers in the town which employed several hundred

men. Leather was produced for shoes, cycle and motorcycle

saddles, motor cars.

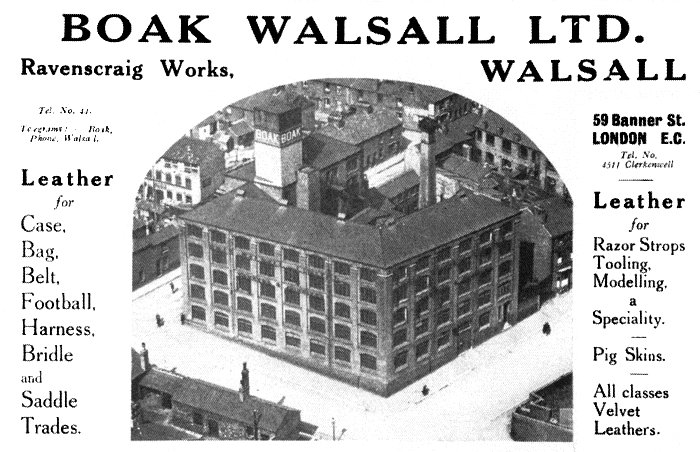

One well known company, Boak, on the

corner of Bridgeman Street and Station Street was producing

fancy leather from calf, sheep, and goatskins. |

|

|

|

|

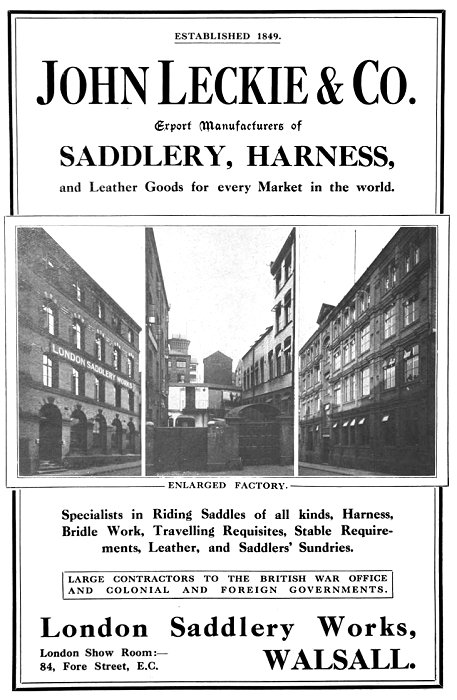

Two adverts from 1899. |

|

|

|

|

|

Messrs. E. T.

Holden and Son, Tanners,

Curriers, and Japanners

A visit to the works in 1897 by

members of the Institution of

Mechanical Engineers

This firm is one

of the largest in the kingdom

for the production of leather,

required for the manufacture of

saddlery and harness, for

upholstery, for coach building,

and for other purposes. It was

founded in 1819 by the late Mr.

E. Holden, whose son is the

present senior partner.

The

manufactory and warehouse are

situated in Park Street, and are

reached through a narrow passage

adjoining the New Inns. What

forty years ago were only one or

two curriers' shops are now the

largest works of the kind in

Walsall; the latest additions

are lofty five-storey buildings.

They comprise offices,

warehouses, depots for hides in

various stages of manufacture,

including scouring shops with a

large scouring drum; compo

houses, with ingenious

mechanical appliances; splitting

shops; finishing rooms;

extensive drying sheds; rooms

and sheds for polishing, for

storage of oil, etc.; also

blacksmiths' and carpenters'

shops.

Here are

produced all kinds of enamelled

and japanned leather, harness

hides, legging hides, horse

hides, leather for military

belts, winkers, bridles, reins,

stirrups, bags, braces, straps,

and fancy articles. A branch of

manufacture requiring most

careful attention is that of

hogskins for racing saddles, for

which lightness is so important

a consideration. The tan yard is

in Beith, Scotland. The goods

are sent from Walsall to London

and the provinces, and also to

the continent and the colonies. |

|

An advert from 1896.

An advert from 1896.

|

An advert from 1899. |

Fancy leather goods produced in the

early 20th century included blotters, footballs, garters,

gloves, ladies' fancy bags, pocket books, razor strops, and

watch guards.

Around this time the cutting-out process was

mechanised and several large businesses merged.

During the First World War the

factories turned to munitions work, and after the war

Walsall became one of the most important centres for the

production of fancy, and light leather goods in the country.

|

A bill head from 1892.

An advert from 1896.

An advert from 1899.

| An advert from 1899. |

|

|

An advert from 1899. |

| An advert from 1899. |

|

|

An advert from

1899. |

| An advert from

1899. |

|

|

An advert from

1899. |

An advert from 1902.

An advert from 1904.

|

An advert from 1916. |

John Leckie & Company made saddles

and leather goods at London Saddlery Works in

Goodall Street.

The firm also had London showrooms at

84 Fore Street.

Products included saddles and harness, fancy

leather goods, bags, cases, waist belts,

leggings, leather scout and girl guide

equipment, and footballs, which were sold at

home and abroad. |

|

Messrs. John Leckie

and Company, Saddlery and Harness

Works

A visit to the works in 1897 by

members of the Institution of

Mechanical Engineers

Walsall is

chiefly noted as a saddlery town,

and has become the centre of this

industry. The export manufacturing

business of this firm, founded

nearly fifty years ago, was

transferred from Glasgow to Walsall

about twenty-five years ago. It had

been in existence for many years in

Scotland, where a large

manufacturing business for foreign

and colonial trade was carried on;

but owing to the facilities for

obtaining materials, machinery, and

labour in Walsall, it was found more

profitable to transfer the industry

from Scotland. They are the largest

manufacturers in the various

branches of the Walsall leather

industry, ladies' saddles, hunting

saddles, harness, army equipment,

belts, strapping, purses, and every

kind of equestrian requirements for

foreign and colonial travel, which

are all classified and worked under

different departments.

The firm

manufacture their own leather; and

the hides after being tanned are put

through different interesting

processes before they become ready

for use in different colours,

textures, and strengths. In the

cutting room the leather is cut up

by hand or by gauge knives, or is

placed under steam power cutting

presses to be cut out into certain

shapes, until gradually the articles

get their final finish. The work is

prepared for stitching by men and

women; the hand stitching is done in

one department by girls and women,

whilst the plain stitching in most

cases is done in the steam power

machine-rooms, where there are about

thirty machines, of all strengths

and makes, both English and

American, are continually stitching

articles from the lightest to the

heaviest.

After the goods

are stitched and inspected they are

finished and sent down to the

packing rooms, where they are laid

aside under different order numbers

until their respective orders are

completed, when they again undergo

an inspection, after which they are

ready to be packed in cases and sent

by rail to the different ports of

shipment. Among some of the articles

produced here are bandoliers for

South Africa, and eight mule span

harness for the Transvaal, regular

Cape harness for the Colonies,

single harness for the East Indies

and Australia, and mule harness for

the West Indian plantations; whilst

in the saddlery workrooms saddles

are made of all styles, for almost

every foreign market and for the

Colonies, especially South Africa.

In addition, some singularly built

saddles have been made for South

America, with the elevated Somerset

cantles and thigh pads, as well as

some high knee padded saddles for

Australia. For the Kaffirs of the

goldfields and elsewhere hundreds of

grosses of money belts have been

made for their arms, wrists, and

waists. A large amount of work is

done for the government, especially

for India and South Africa. The

number of workpeople employed is

about 300. |

|

|

An advert from 1935. |

|

An advert from 1935. |

| |

|

Leather and allied

trades listed

in the 1935 Walsall Red Book |

|

| |

|

| In the 1950s the industry suffered

because of competition from products made of artificial

leather.

By the 1960s tanning was in decline, but over

600 people still worked in the industry.

In 1970 there were

around 50 leather goods manufacturers in Walsall, and

the town produced around half of the British-made fancy leather

goods.

A small number of saddle and harness

makers survived, producing high quality, hand-made items,

mainly for the top end of the market.

In recent times there

has been a revival in the saddlery trade, which has ensured

that Walsall’s saddle making industry will survive into the

foreseeable future.

More leisure time and televised

equestrian events led to increased interest in horse riding

for pleasure, and a dramatic revival of the quality saddle

making industry. |

An advert from 1954. |

|

|

|

|

|

Two adverts

from 1974. |

|

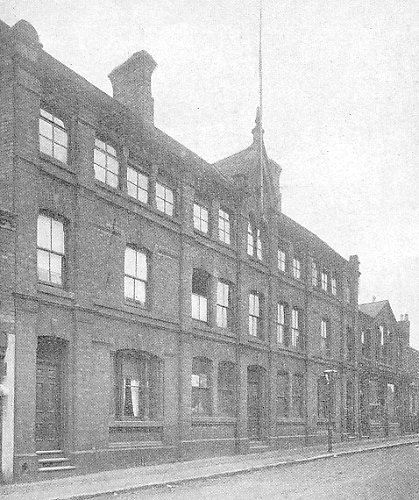

| Imperial Leather Works

in 1914, premises of Moss, Stone & Company. It

is now occupied by Lovatt & Ricketts, and called

Clifford House. |

|

Moss, Stone & Company of Imperial

Leather Works, Butts Road was founded in 1898 by Mr. Alfred

Moss.

The firm manufactured saddlery of all

kinds and specialised in light saddlery for racing,

steeple-chasing, exercising, and polo, which was used in the

principal races and polo clubs.

Another product, solely manufactured by

the company was the patent ventilated, extremely light

saddle invented by Robson, of York.

In 1913 the company acquired the old

established business of the late Mr. Thomas Ash, Paragon

Works, Walsall, together with the goodwill, patents, trade

marks and manufacturing rights.

The company also produced fancy leather

goods including purses, pocket books, jewel cases, music

cases, camera cases, attache cases, suit cases, watch

guards, wristlets, braces and men's belts, blotters, dog

collars, leads, and dog sheets. |

|

The firm was also a large Government

contractor, making all kinds of military saddlery, harness,

and equipment for the War Office, and patented a side saddle

called the ‘Climax’, and a saddle called the ‘Eldonian’

which was bought by Jeffries in 1987. The London Offices

were at 63, Queen Victoria Street.

Harwood & Sons of Glebe Works, Glebe

Street was founded in 1894 to manufacture high class leather

goods.

Products included American and English

buggy saddles, harness collars, coupé saddles, rein holders,

winkers, pad cloths, letter cases, purses, ladies' bags, dog

collars, belts etc.

The firm also carried out bridle

cutting, and was a contractor to H.M. Government.

Another manufacturer T. H. Crumpton & Company of 48 Stafford

Street produced harnesses and claimed to possess the oldest

harness factory in the world. The firm specialised in

sweat-proof collars and sweat-proof lined saddles, and made

every kind of harness, from dog and goat harness to elephant

harness. |

|

|

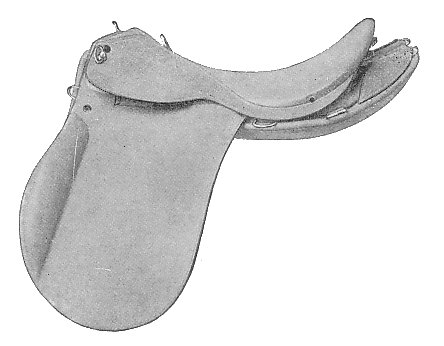

A Stone & Roberts saddle. |

Stone & Roberts of 43 Wednesbury Road

were a well known manufacturer of high class saddlery.

The firm designed and made saddles for

military and other purposes, suitable for all climates.

The saddles were sold at home and

abroad, many going to

India, Australia, and New Zealand.

|

|

|

|

|

More adverts

from 1974. |

|

|

Finishing pig skin leather, ready for

export. |

Today’s manufacturers include E. Hulme

& Son Limited, the largest manufacturer of small leather

promotional and advertising gifts in the country, Peter

Yates Leathergoods Limited, manufacturers and importers of

leather, and producers of a range of products including

conference folders, travel wallets, and business accessories.

Ancol make collars and leads for pet owners, using the best

bridle leather, and Nevada leather goods produce the

extensive Abbeygate collection of promotional diaries and

striking leather gifts.

W. Lees (Walsall) Limited is an

established manufacturer of men's leather belts, and braces,

serving both the wholesale and retail trade. |

|

Jabez Cliff and Company

The firm, which became one of Walsall’s

most successful, and longest surviving saddle makers was

founded by Jabez Cliff, whose father George began his

apprenticeship at a Walsall saddlery company in 1793. George

lived with his father George senior, his mother Elizabeth,

three brothers, and a sister in Badger’s Yard in Park Street

where George senior made leather breeches in a small

workshop behind his home. George began his apprenticeship at

the age of 13 and learned how to make bridles.

George later married and had several

children, all except one dying young. The surviving son

Jabez started his own saddlery business in 1873 when he

founded Jabez Cliff and Company, in Portland Street,

Walsall. Eight years later tragedy struck when Jabez and his

two sons Samuel and George died in the terrible typhoid

epidemic that swept across the country. Luckily his wife and

daughter Mary managed to keep the business going. In 1882

Mary married Frederick Tibbits, a skilled bridlemaker who

joined them in the firm.

In 1902 their son Jabez Cliff Tibbits

joined the firm. In 1906 he purchased J. A. Barnsby and

Sons, saddle makers at Globe Works in Lower Forster Street.

The two firms amalgamated and produced saddles under the

Barnsby name, bridleware under the Cliff name, and created

the saddlery brand of Cliff-Barnsby. |

|

The firm exported many of its products

to Russia and Germany, but as the First World War loomed,

Jabez realised that other markets, and other products had to

be found. The firm them diversified into the production of

sports products and leather goods, including cricket balls,

soft-balls, golf bags, holdalls, leather cases and travel

goods.

The firm developed and patented a

none-tear football which came to fame in four FA cup finals,

and in the 1928 Olympic Games.

In 1929 the firm exhibited basket

balls, cricket balls, footballs, hockey balls, polo balls,

tennis balls, volley balls, bowl bags, golf bags, sports

bags, belts, dog collars, riding saddlery, and travelling

requisites at the British Industries Fair.

The company’s managing director Jabez

Cliff Tibbits served on Walsall Council for Hatherton Ward.

He was elected Lord Mayor of Walsall in 1939 and 1940, and

became an Alderman in 1941. He also became a Justice of the

Peace. |

An advert from 1974. |

|

An advert from 1974. |

During the Second World War the firm produced Bren gun

pouches, webbing, and ammunition belts, and formed links

with the military that would continue for years to come.

The firm’s display at the 1947 British Industries Fair

included Barnsby saddles, bridles, reins, head collars,

Globe footballs, baseball balls, cricket balls, hockey

balls, netball balls, rounders balls, water polo balls,

leather travel goods, golf bags, and sports bags.

In 1948 Jabez Cliff Tibbits, who lived

at Cedar Court in Aldridge was knighted by King George VI

for his services to Walsall, and became known as `Sir

Cliff`. He died in 1974.

During the Falklands War in the early

1980s the firm supplied the task forces with pack saddlery

so that vital weapons and equipment could be transported by

mules. For this work the queen awarded a Royal Warrant as

Saddler and Loriner to the firm, which also supplied

saddlery equipment to the Kings Troop, the Royal Horse

Artillery, the Household Cavalry, the Metropolitan Police,

the City of London Police, and also ceremonial equipment to

countries throughout the world. |

|

The firm became one of the top five

saddlery businesses in the world, exporting saddles and

leather goods to many countries. In 2009 Jabez Cliff &

Company Limited moved from Globe Works to new premises in

Aldridge Road. It was the start of a new era. The buildings

were officially opened by HRH the Princess Royal on Tuesday

21st September 2010, and the future looked bright. The firm

was then to be known as Barnsby, and the new buildings were

called Badgers Yard.

In August 2011 tragedy struck at the

firm’s old premises in Lower Forster Street which were

destroyed by fire. The building had been earmarked to become

a £3m health centre with two doctors’ surgeries, an optician

and a pharmacy.

Barnsby concentrated on sporting goods,

saddlery and other fine leather goods, much of which was

exported to the USA, Western Europe, the Far East, Africa,

the Middle East, Australia and the Pacific Rim.

|

|

Using a

leather cutting machine. |

The firm’s saddlery was used by many of the leading professional

riders, but by the beginning of 2014 things had started to

go wrong. Seven people were made redundant from the sales

department, the office, the factory and the warehouse, but

the firm remained confident that profits would soon

increase.

The company’s creditors agreed to

reduce their debts to manageable levels, and everyone worked

hard to increase sales, but the bottom had fallen out of the

market.

On 17th June, 2014 the Birmingham Post

reported that Barnsby has ceased trading due to a failed

restructure and has gone into administration. The remaining

twenty six staff were made redundant, and Andy McGill,

partner at the Birmingham office of Smith & Williamson, was

appointed as administrator. A very sad end to an old and

well-respected firm, whose future had seemed so bright only

a few years earlier. |

|

Sewing fancy

leather goods. Courtesy of John and Christine Ashmore. |

|

Saddle makers include King's Saddlery,

which is famous across the equestrian world, and Albion

saddle makers who make a range of high quality products for

horse owners.

Another saddle maker is E. Jeffries & Sons Limited in

Bridgeman Street. The business was founded in 1820 and has

become a well known name in the horse world. The firm

designs and manufactures saddlery, bridlework, and riding

equipment using the latest technology and materials combined

with traditional manufacturing skills and craftsmanship.

High quality leather is still produced

in the town. J & E Sedgwick & Company Limited was founded in

1900 by James and Emmanuel Sedgwick, who were later joined

by Richard Farrow.

The company is one of the leading

suppliers of equestrian leather in Walsall and maintains an

active recruitment and training programme for new young

apprentices. |

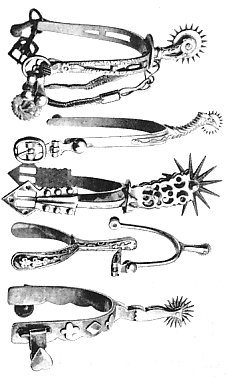

Examples of Walsall-made spurs. |

|

Messrs.

John Dewsbury & Son, Bridle Bit and Nickel

Plating Works, Littleton Street

A visit in 1897 by members of the

Institution of Mechanical Engineers

These works were

founded by the late Mr. John Dewsbury in

1840 in Duncalf Street, Walsall, and the

increasing business was soon afterwards

removed to Littleton Street. Here bridle

bits are produced in all qualities, sizes,

and patterns; among the novelties are bits

made with India rubber mouthpieces for

tender mouthed horses, the chains inside

being tested to stand a pull of 500 lbs.;

and medicine drenching bits, by which

medicine may be easily given to horses and

cows.

Besides the usual

japanned, tinned, and nickel plated goods,

bits in solid nickel silver are extensively

made. In the new nickel plating process

steel articles are placed in a perforated

cage, through which runs a brass rod

connected electrically by its bearings with

the rods that suspend it; the cage is spun

in the green solution of nickel, and as the

articles jolt about inside they take on the

metal and polish themselves against one

another. Some bits are cast, but most are

forged; and skilful work is required to

snake the two halves of a light snaffle

exactly alike. For making rings, a rod of

steel is drawn from the forge, twisted

round, run through a hole, welded, and

moulded to shape with a few blows on a plug;

the extra metal at the joint is removed by a

file.

The first polishing

takes place in revolving cans amid sand and

water or emery and oil; the last is

performed on calico wheels with tripoli

rubbed on from the cake. An interesting

process is the making of moulds from the

drawings. A piece of lead is carved to

resemble the drawing as nearly as possible,

from which a mould is taken in sand, and a

casting made; the latter is then carved

until it truly represents the drawing, and

is then moulded, and another casting taken

from it, which becomes the lead pattern for

future use. The number of workpeople

employed is 100. |

|

|

In 1971 the old established firm, Boak

Currying Company Limited, was acquired by James Garnar &

Sons Limited of London. The name of the company was then

changed to Garnar Boak Limited. Mr. R. G. A. Boak continued

as Managing Director, and new machinery and working methods

were introduced to increase production.

This enabled the business to extend its

market share, particularly abroad. The high quality products

include pigskin leather, hide, E.I. Kips and calf leather

which is ideally suited for the production of saddlery,

bridle, and fancy goods.

|

Garnar Boak Limited's factory can

be seen on the left of Bridgeman Street, with the Anchor

pub on the right. Sadly the factory was destroyed a few

years ago after a mindless arson attack. Taken by

Richard Ashmore. Courtesy of John & Christine Ashmore. |

|

Another successful business, the

Vantage Leathergoods Company, founded in 1899, manufactures

a wide range of leather products from many types of leather.

The products, which carry the 'Vantage' trade mark, include

ashtrays, billfolds, folio cases, brushes and brush sets,

pocket flasks, key purses, manicure sets, notecases,

shoe-shine kits, spectacle cases, stud boxes, tobacco

pouches, travel slippers, wallets, wet packs, and writing

cases. |

|

Invoice letterhead from the

1960s, from Butler Brothers, leather supplies. |

| Specialities (Leather) Limited, founded just before

the First World War, produced a range of purses,

wallets, tobacco pouches, and shopping bags, etc. that

were sold both at home and abroad. They also produced a

range of novelty goods under the name of "St. Crispin".

The firm initially had premises in Bridge Street,

Walsall, but due to early growth larger premises were

soon required and so the firm moved to Stafford, where

it stayed for some time. Several years later a new

purpose-built factory was erected at Goscote where goods

were made on a conveyor belt system, the first time this

technique had been used in the leather trade. All went

well until the Second World War when the factory was

requisitioned. In order to carry-on with production of

fancy leather goods, the firm used other factories, some

as far away as London. Although recovery was difficult

after the war, the company prospered, soon producing a

range of over two hundred items at four sites in

Walsall, including a wide range of shopping bags.

|

An advert from 1954.

| |

|

| Read about Joseph Carver's

firm which produced whips, then moved into engineering |

|

| |

|

|

Return to

Walsall Industries |

|