|

Tube

Making

Crown Tube Works

The birth of one of Wednesbury’s

most famous industries took place in 1811 when John

Russell, gun barrel maker, and landlord of the Turk’s

Head Inn began to make wrought iron tubes.

|

|

At the time there was a shortage of

good quality tubing for use in steam engines, and more

importantly for distribution of the gas supply, thanks

to William Murdoch’s invention of gas lighting in 1792.

John Russell began to produce

tapered tubes which pushed together, but were very

difficult to make. As a result, John and his elder brother

James developed a hand-forged wrought iron socket for

joining parallel tubes together. Aaron Manby of Moxley

decided to manufacture the new invention, and offered

James employment at his new works.

In 1816 John decided to set up a

tube works on the corner of Wellcroft Street, Church

Hill, in partnership with James, who ran the business.

|

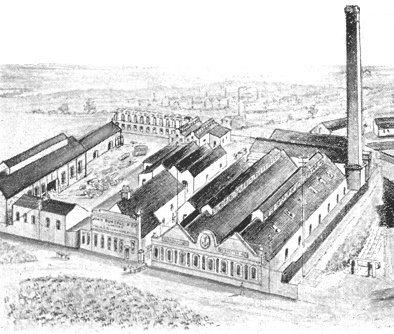

John Russell's Old Patent Tube Works at

Wednesbury. |

John Russell's trade mark.

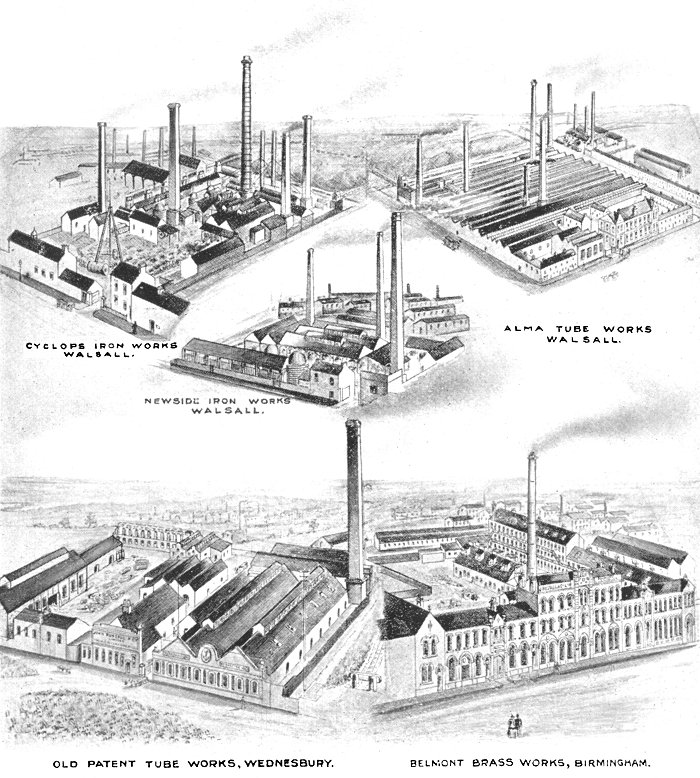

The firm's factories in 1916.

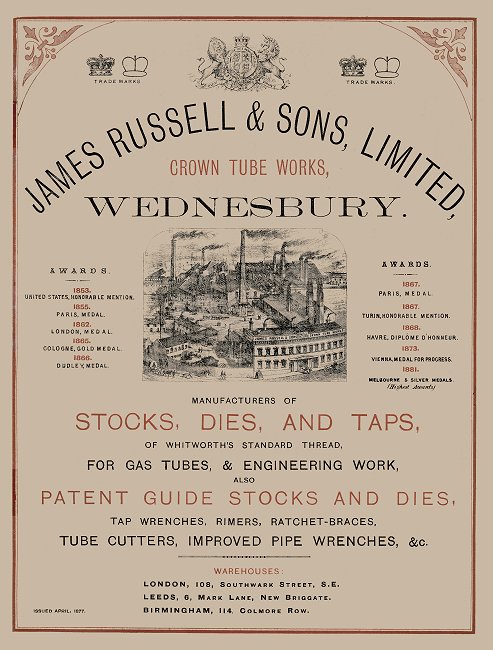

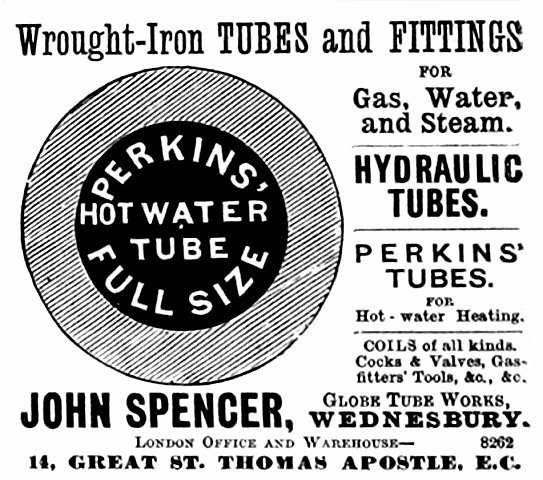

An advert from 1862.

An advert from 1899.

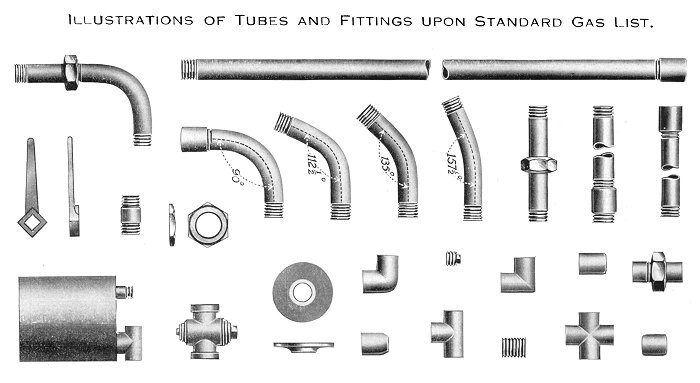

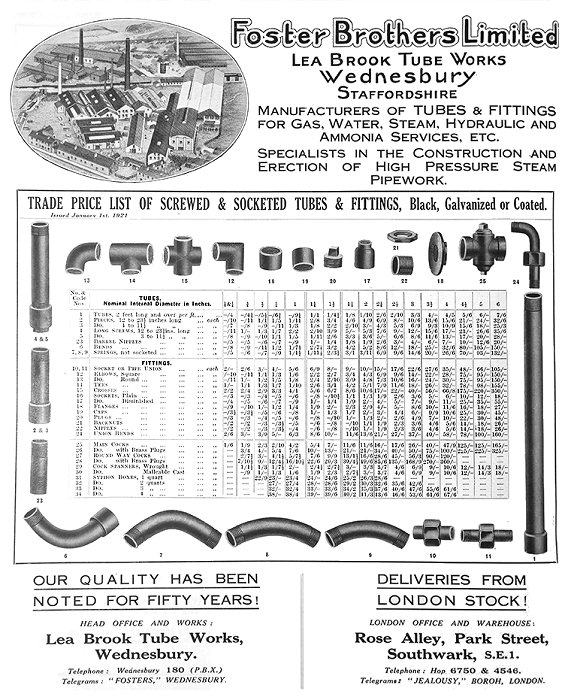

John Russell & Company Limited's tubes and

fittings on sale in 1899.

| 1. |

Tubes 2 to 14ft. long |

16. |

Plain Socket |

| 2. |

Pieces 12 to 23½

inches long. |

17. |

Diminished Socket |

| 3. |

Pieces 3 to 11½

inches long. |

18. |

Union Bend |

| 4. |

Long Screws 12 to 23½

inches long |

19. |

Iron Main Cock |

| 5. |

Long Screws 3 to 11½

inches long |

20. |

Malleable Cast Elbow |

| 6. |

Bends |

21. |

Iron Main Cock with Brass Plug |

| 7. |

Springs not socketed. |

22. |

Cock Spanner |

| 8. |

Springs not socketed. |

23. |

Syphon Box |

| 9. |

Springs not socketed. |

24. |

Flange |

|

10. |

Socket Union |

25. |

Cap |

|

11. |

Pipe Union |

26. |

Plug |

|

12. |

Square Elbow |

27. |

Back Nut |

|

13. |

Round Elbow |

28. |

Nipple |

|

14. |

Tee |

29. |

Barrel Nipple |

|

15. |

Cross |

|

|

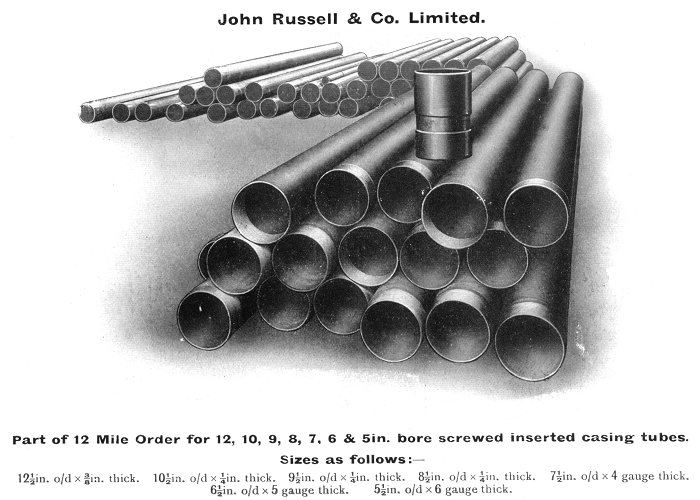

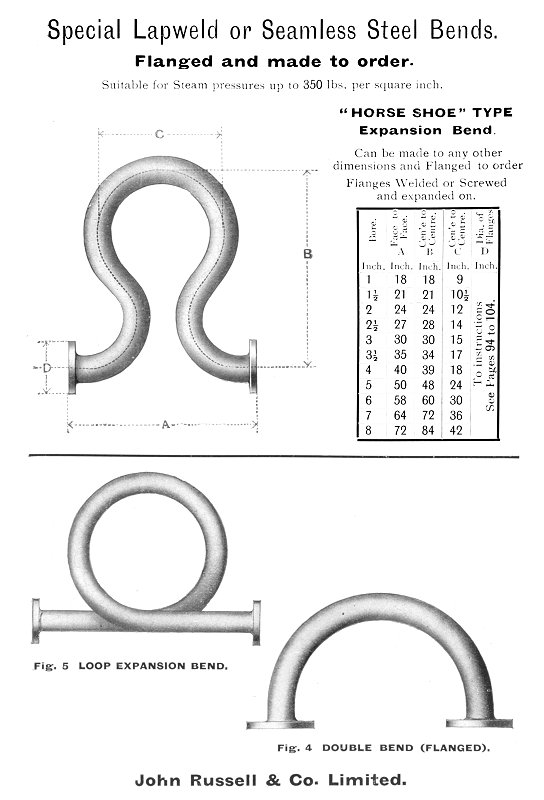

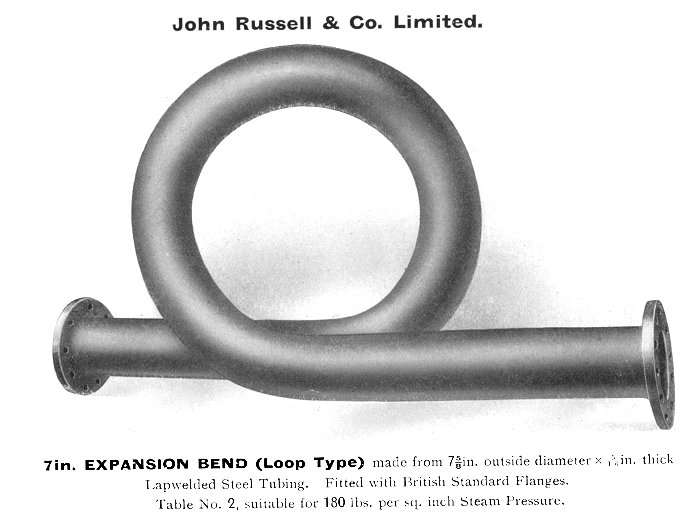

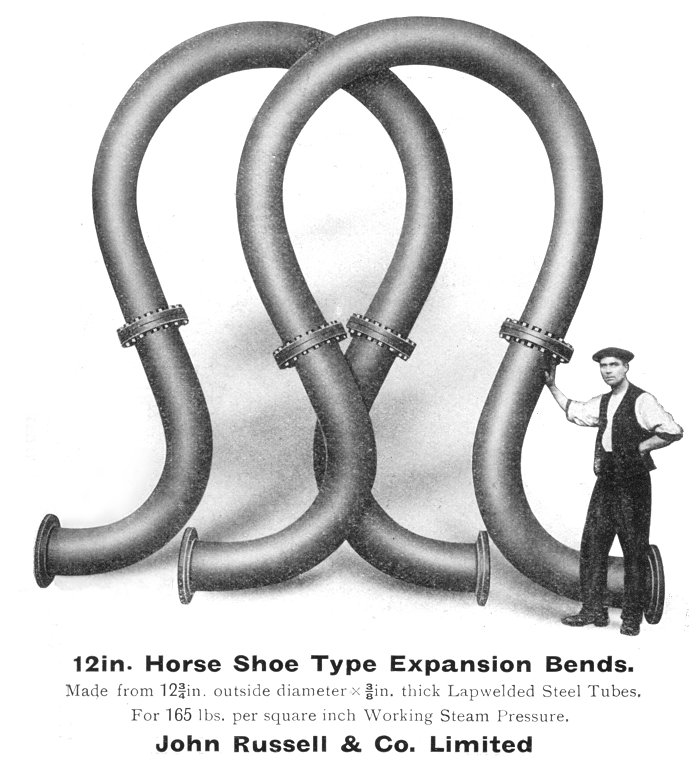

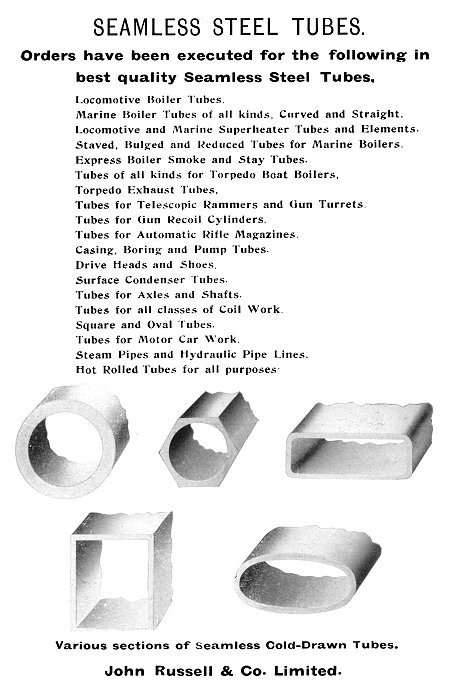

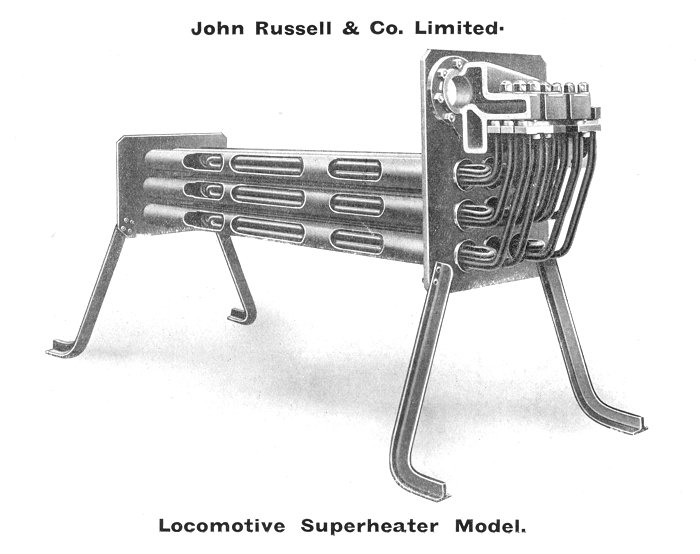

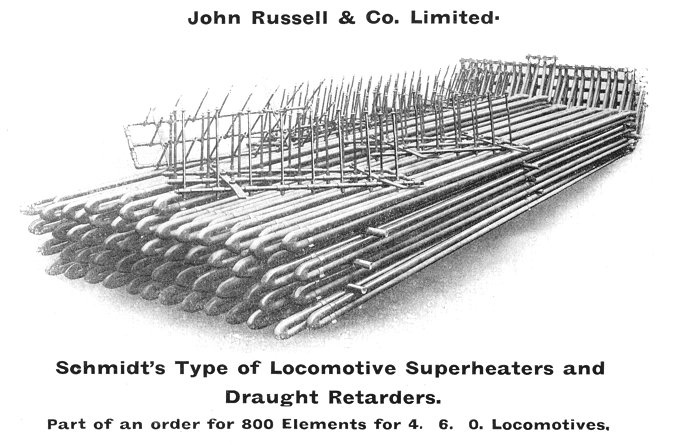

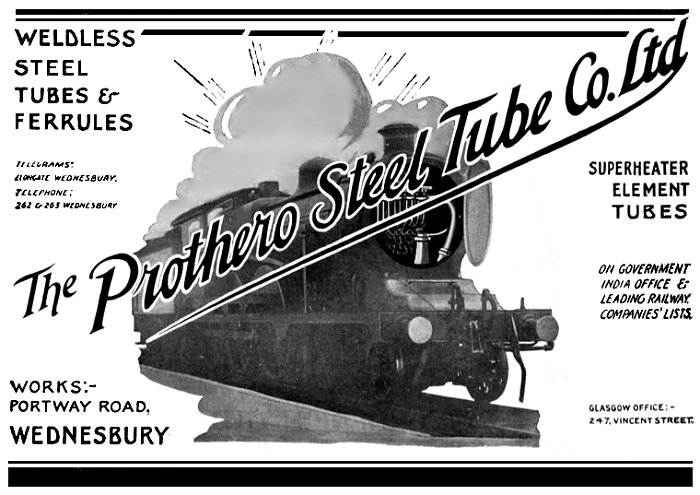

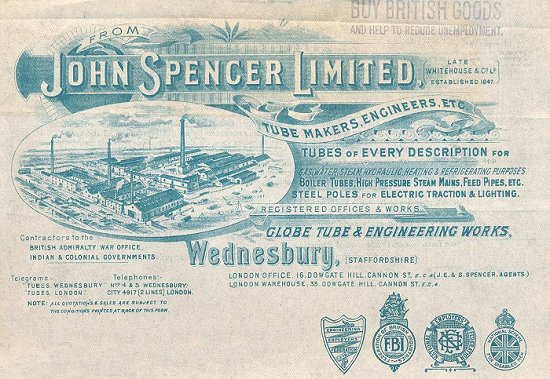

An advert from 1916.

An advert from 1916.

An advert from 1916.

An advert from 1916.

An advert from 1916.

An advert from 1916.

An advert from 1916.

An advert from 1916.

|

In 1823 James left and founded

Crown Tube Works at the High Bullen, after securing a

patent for butt welded tube. John subsequently founded

John Russell & Company. After his death in 1853 much of

the manufacturing moved to the new and larger Alma Tube

Works in Walsall, but the company also continued to use

the old Wellcroft Street works.

Tubes were originally formed from

an iron strip, or skelp as it was known, which was

heated in small sections, a few inches at a time, in a

conventional blacksmith’s fire. Each section was

hammered into shape, each side of the seam being

overlapped and hammered to form a weld.

The whole

process took a long time as many heatings and hammerings

were required to form each length of tube. The process

was expensive, and labour intensive. Many tube forgers

were employed in the works, and the tubes were produced

in lengths of around 4 feet.

As a result of the primitive

manufacturing techniques then in use, the industry

couldn’t keep up with the growing demand for tubes, and

so something had to be done to both increase the supply

and reduce the manufacturing costs.

|

An advert from 1918. |

|

Cornelius

Whitehouse. |

The solution came in 1825 thanks

to Cornelius Whitehouse who worked for Edward Elwell at

Wednesbury Forge. He heated the whole strip in one go,

in a hollow fire of the type used by the edge tool

makers at the forge. He then shaped the strip and welded

the edges of the seam in one operation by drawing it

through a pair of semi-circular dies.

During the process the tube was butt

welded so that the edges of the seam were joined without

an overlap. The process produced an accurately shaped

tube with smooth inside and outside surfaces. Whitehouse had no need for his

invention, and on Elwell’s suggestion he took it to

James Russell who agreed to help him take out a patent

for the process. |

| |

|

|

Read about Cornelius

Whitehouse |

| |

|

|

An advert from 1896. |

After the patent had been granted,

Russell purchased the rights from Cornelius on the

understanding that he would pay him the sum of £50

annually for the life of the patent. The invention

revolutionised the industry, because for the first time

tubes could be made quickly, cheaply, and in longer

lengths. Originally a man could produce around 25 four

foot lengths in a day, but now the same man could

produce 200 eight foot lengths in the same time. As a

result Crown Works now led the industry and became well

known throughout the world.

Unfortunately success came at a price. Other

manufacturers, still using the old methods, greatly

resented the company, also the tube workers who had lost

their jobs because of the introduction of the new

process, were very angry. Cornelius Whitehouse was even

fired-on by hostile demonstrators and as a consequence

always kept a loaded gun by his bedside. Russell built a

high brick wall around the works, topped with iron

spikes, to keep out the hostile crowd and prevent anyone

stealing the secrets of his process. F. W. Hackwood

mentions that some of the would-be spies even rented a

row of houses that were adjacent to the works, in the

hope of observing the process. |

|

As well as producing tubes of all

kinds, the company also made a wide range of tools for use

with the tubes, and also for use in industry generally.

The image on the left shows the front

cover of Russell's April 1877 tool catalogue. |

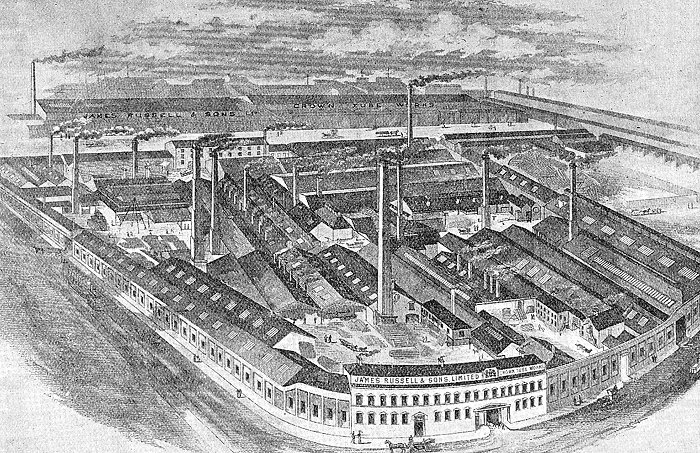

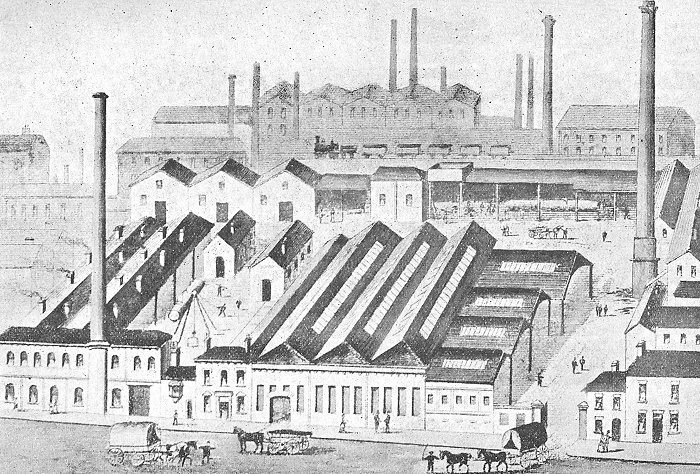

| A lovely image of Crown Tube Works

from the April 1877 tool catalogue, as seen above. |

|

| Some of the tools from

the 1877 catalogue: |

Crown Tube Works in 1905.

|

Russell had to

spend large sums of money towards legal proceedings to

protect his patent from infringement. In 1838 he

obtained a 6 year extension for the patent on the

understanding that he would pay Whitehouse £500 annually

during that time.

Crown Works became one of the town’s

most important employers and the extension of the patent

was celebrated in the town. By James Russell’s death in

1849 the works employed around 200 men who were

producing well over 4 million feet of tubing a year.

After his death the works were run by his son John James

Russell and by 1865 were producing over 5,300,000 feet

of tubing a year. John added a foundry to the works to

make tube fittings and built a mechanic’s institute for

the workers, complete with a library, classrooms and

lecture hall.

In 1866 John

found himself in financial difficulties through no fault

of his own. The company’s London agent had been

embezzling large sums of money, which resulted in the

business being transferred to a limited company; James

Russell & Sons Limited. John became chairman and most of

the shares were purchased by the company’s employees.

|

An advert from 1905. |

|

An advert from 1873. |

Crown Works retained its dominant

place in the industry in spite of other large UK

manufacturers, and exported its products to many

countries including France, Germany and Russia.

By 1889 nearly 1,100 people were employed at the works,

and before the turn of the century the company opened a

galvanizing plant at Darlaston.

The 1880s saw

the introduction of steel making in Wednesbury using the

Siemens open hearth furnace, and as a result Crown Tube

Works began to produce seamless steel tubing, but their

main products were still made from wrought iron, which

continued to be popular because it didn’t corrode when

used for water or gas.

By the turn of

the century the Crown Tube Works began to suffer from

lack of investment, which would eventually lead to its

downfall. |

|

Striker's wives and children

queuing for bread. |

In 1913 a large strike began in Wednesbury, which

effected many of the local companies.

It started on 9th May when 200 workers from Crown

Works demanded higher wages. Large numbers of strikers

gathered in the Market Place |

| The strike had a great impact on the local companies

and was a time of great hardship for the strikers. The

strike eventually ended after the employers agreed on a

minimum wage of 22 shillings a week for unskilled

labourers.

They also agreed to allow their workers to join

trades unions. |

Strikers gathering in the Market

Place for handouts of free food. |

|

The works still

relied heavily on man power. During World War One the

wages bill amounted to 27% of their sales. A proposal to

modernise the works and install the latest machinery led

to a disagreement between the directors, which got

completely out of hand. Things were so bad that the

business could not continue to operate, and as a result

87% of the capital was acquired by John Russell &

Company who set about the task of sorting things out.

The new owners

found that the factory was “a rabbit warren of small

shops impossible to supervise”. Many of the antiquated

machines were only suitable for scrap, the men were

obstructive and the foremen had no control over them.

They were very critical of the management, who had no

accurate means of stocktaking or analysis of sales, and

hardly ever visited their depots.

Crown Tube Works was bombed in

World War One during a Zeppelin raid. On 31st January,

1916, nine German Zeppelin airships left their bases to

carry out bombing raids over England. The target was

Liverpool, but two of them got lost and ended-up over

Wednesbury. One of them, L21, captained by 45 years old

Max Dietrich dropped bombs on Tipton, Bradley,

Wednesbury and Walsall before returning home. As it

neared Wednesbury, the airship flew across the

relatively dark area of Lea Brook, heading for the

brightly lit town centre. As it travelled towards the

High Bullen, bombs were dropped around King Street and

on the Crown Tube Works, setting the huge factory

alight.

Sadly one of the bombs destroyed

the house at number 13 King Street and badly damaged

number 14 next door, killing four members of the Smith

family. They were Joseph Horton Smith, aged 37, Nellie

Smith, aged 13, Thomas Smith, aged 11, and Ina Smith,

aged 7, whose body had been blown onto the roof of the

tube factory. |

|

The advert opposite and the

text below were taken from the 1918 Wednesbury Official

Handbook. |

A letterhead from 1929.

|

An advert from 1922. |

The decision was

taken to close and demolish Crown Works and temporarily

transfer the business to their Walsall factory and the

old Wellcroft Street works at Wednesbury. They

also opened a new tube works at Runcorn and built a new

Crown Tube Works at Hill Top, near the railway and the

Tame Valley Canal. Unfortunately both ventures were

unsuccessful and the company sold out to Stewarts and

Lloyds in 1929.

In 1928 Stewarts and Lloyds also

acquired another tube works in Wednesbury, the Prothero

Steel Tube Company Limited, founded in 1926. They

manufactured hot rolled and cold drawn weldless tubes.

Just before the outbreak of war in 1939 the Crown Works

were equipped with shell making equipment to produce

shell forgings as part of the war effort.

One remnant of the old Crown Tube

Works at the High Bullen remained until 1989, that was

George Croft's Bright Drawn Steels.

|

An advert from 1927. The

Prothero Steel Tube Company Limited, Portway Road,

Wednesbury manufactured hot rolled and cold drawn

weldless tubes. |

The frontage of John Russell's Old Patent

Tube Works can now be seen at the Black Country Living Museum.

|

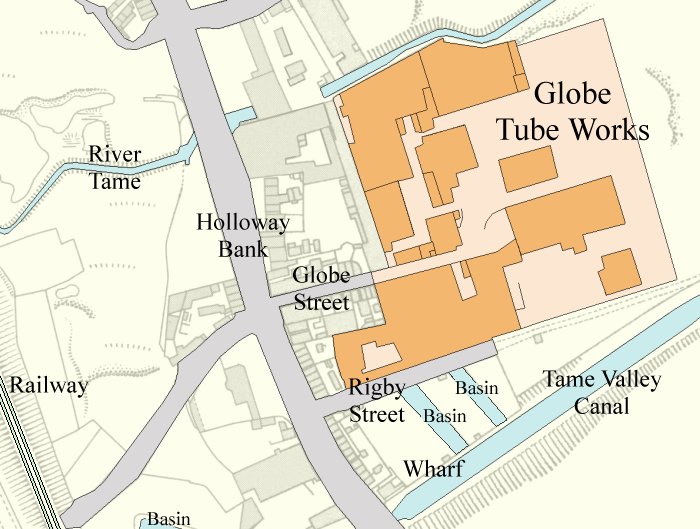

Globe Tube Works

In 1849

Cornelius Whitehouse founded the Globe Tube Works at

Holloway Bank, the first joint stock limited company in

the town. Unfortunately he was no businessman and the

company failed in the 1875-1886 depression, the only

tube works to do so. He died in poverty in 1883. The

works reopened in 1882 after being acquired by John

Spencer. The factory remained in business until 1935

when John Spencer Limited was taken over and closed by

Stewarts and Lloyds.

|

The location of Globe Tube Works.

A letterhead from 1927.

|

The advert opposite and the

text below were taken from the 1918 Wednesbury Official

Handbook. |

An advert from 1889.

|

Other Early Tube Works

In the 1850s and

1860s a number of ex-Crown Works employees set

themselves up in business making hand-forged tube

fittings. Such enterprises required little start-up

capital and mainly relied on the skill of the workers.

One of them, John Knowles, who founded Walsall Street

Works in 1850 went on to become the main producer of

tube fittings. Others tube manufacturers were Job

Edwards’ Junction Works founded in 1863, and Eagle Works

founded in 1880. The business was eventually taken over

by Wellington Tube Works.

James McDougall

founded the highly successful Hope Patent Tube Works in

1869 which became the first factory in the area to

produce weldless tubes. Sales of the tubes were

extremely high thanks to their many and diverse uses

including bicycle frames and bedsteads. In 1913

McDougall purchased the Imperial Tube Works from Isaac

Griffiths & Sons Limited.

|

An advert from 1922. |

|

The text above and the advert

below were taken from the 1918 Wednesbury Official

Handbook. |

Hope Patent Tube Works produced a

wide range of products including:

|

bedstead, blind, and

fencing tubes, and ferrules; special light

tubing; oval and flat tubing; cold-drawn

weldless tubes for cycles; boiler tubes;

electricity conduit tube; electrical

fittings; sanitary flush pipes; strong tubes

for hand rails etc; gas, steam, and water

tubes, and appropriate fittings |

The company was eventually taken

over by Helliwell's Aircraft.

|

|

An advert from 1922. |

|

|

The list of tube makers in Cope's

Wednesbury & Darlaston Blue Book of 1922. |

|

|

An advert from 1908. |

From the 1918 Wednesbury Official

Handbook.

From the 1918 Wednesbury Official

Handbook.

|

An advert from 1918. |

|

An advert from 1851. |

|

An advert from 1918. |

|

An advert from 1918. |

|

From the 1918 Wednesbury Official

Handbook. |

|

An advert from 1905. |

|

An advert from 1918. |

Eagle and Junction Tube Works.

An advert from 1865.

| Foster Brothers

Thomas Foster was an ex-Crown Works employee, who

later worked at Globe Works, Wednesbury and Ridgacre

Lane Tube Works in West Bromwich. In 1887 his two

sons, Thomas and Humphrey founded Ratcliffe and

Foster with Mr. Ratcliffe, an experienced

businessman. The business was set up at the site of

the old Lea Brook Iron Works, alongside the Walsall

Canal in Leabrook Road, where their first batch of

tubes was produced in 1888.

In 1893 Thomas Foster senior,

helped his sons to buy-out Mr. Ratcliffe and the

firm was incorporated as Foster Brothers Limited.

Unfortunately before the transaction was completed,

Thomas junior died, leaving Humphrey in charge. A

few years later, Thomas senior died. He had been

running the tube works in Ridgacre Lane, West

Bromwich, with another of his sons, John Foster. The

West Bromwich site was sold and John joined his

brother Humphrey at Leabrook Road, bringing much of

the better machinery from Ridgacre Lane with him.

By this time, Foster Brothers

was very successful, producing tubes, wrought-iron

fittings, cocks and valves, both in iron and brass.

Many of the products were exported throughout the

world. In 1902, Humphrey junior joined the firm, as

did his younger brother Kenneth in 1918. The firm

also manufactured tubes for the railway companies

and specialised in high pressure tubes and fittings.

By the 1960s the firm had

expanded with the formation of two subsidiary

companies, Foster Brothers (London) Limited, based

at Clapham and Foster Brothers Plastics Limited at

Wednesbury.

Sadly the business went into

liquidation in 1985, when liquidators were

appointed, as can be seen from the following notice

in the London Gazette.

|

|

Decline of the Industry

In the 1850s and 1860s competition

from the new tube works at Halesowen, Birmingham, and

Wolverhampton began to have an effect on Wednesbury's

tube industry.

In 1900 the town still had a monopoly on

tapered tubes that were mainly used for telegraph poles

and electric tramways. The two main suppliers were Crown

Tube Works and Globe Tube Works. |

|

America and Germany increased their import duty on

imported tubes to protect their own manufacturers, who

by 1914 were exporting large quantities of tubes to the

UK.

By World War One Wednesbury had lost its dominant

position in the industry. The largest manufacturer at

the time, Stewarts and Lloyds, of Halesowen easily

exceeded Wednesbury's total annual production.

Wednesbury's older factories were suffering from a

general lack of much needed investment. Much of the

machinery was old-fashioned and by 1906 the wages bill

amounted to 84% of the total production cost.

The town

continued to concentrate on iron tubes and by the 1930s

many of the factories had closed. |

|

In 1924 Griffiths & Billingsley

Limited, of Alma Street was purchased and closed by the

British Tube Association. In 1935 it was the turn of

Edward Smith Limited, who were purchased and closed by

the Wellington Tube Works.

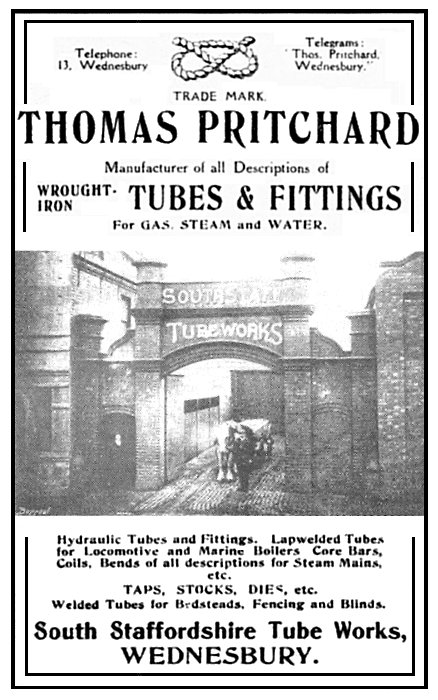

Other companies survived for much

longer. John Knowles Limited of Walsall Street was

purchased by Tipper Brothers. It was still going in the

1960s as were Thomas Pritchard & Company, and Foster

Brothers.

In 1937 a new company, founded by

Percy Newman appeared, and

built a large up-to-date factory. This was Newman Tubes

Limited in Holyhead Road who began to produce cold drawn weldless steel tubes.

In 1947 a new automatic mill was installed for

the production of electrically welded tubes.

The business became Newman-Monmore

Tubes of Western Way, one of Wednesbury's main

tube producers.

|

An advert from 1949. |

|

Return to

industries |

|