|

Other Industries

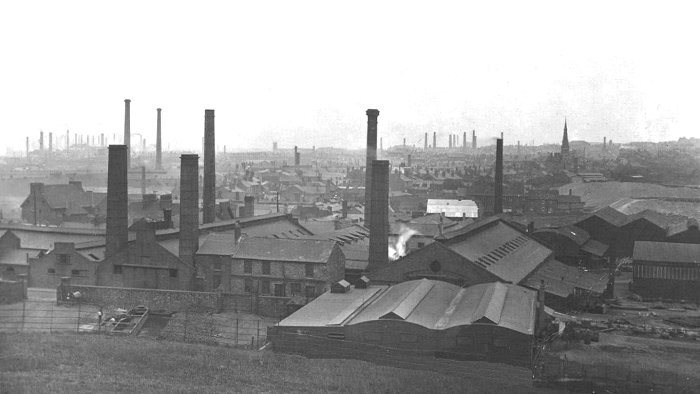

Wednesbury was at the centre of a

vast area of industrialisation, which greatly affected

the landscape and everyday sights and sounds.

In 1854 John Nock Bagnall published

his book "A History of Wednesbury in the County of

Stafford" which includes a chapter describing Wednesbury

as it was at the time. In the book he describes the view

from Church Hill at night:

|

Notwithstanding the great change that

has taken place in the appearance of the

surrounding country, there are but few

places which afford so extensive and

striking a panorama of the mine and

metal district as Wednesbury Hill,

"taking in," as a modern historian

expresses it, "within its lofty glance

the burning, fiery furnaces of West

Bromwich, Tipton, Coseley, Bilston, and

Darlaston; the horizon, miles upon

miles, dotted about with smoking,

blazing coke hearths, appears under the

black, sooty roof of nightfall, like a

large illuminated minster, devoted to a

ritual of the ancient Parsees, or fire

worshippers, and eclipsing the very

clouds of heaven in their gigantic

wreath of incense.

And a strange, wild, savage music seems

to accompany these loud litanies; bell

and ball, hammer and shears, crank and

chains, wheels and rolls, steam, blast

and engine screams, yell and howl, and

shriek and roar and hiss, and above them

all, the big shout of the forgeman, or

call of the collier, seems ever and anon

to set them yelling, howling, shrieking,

roaring, and hissing with a renewed grim

energy, as if they were resolved to

deafen every other tone of mortal sound

except their own hideous minstrelsy.

And when the mild, quiet moon looks down

at times upon the riot, like a 'blue

light' on a field of fireworks, so

stillness looks more still in the

contrast of the rioting, and she seems

timidly to steal away faster than usual

through the mountain masses of drifting

smoke clouds, that irreverently smoke

her face as if she was a common street

lamp.

The stranger shudders as he beholds the

scene. Far as the eye can reach it is a

series of fires; there seems to be too

much fire and too much fury to be ever

put out again. The dread is that it must

grow and spread beyond its flaming

boundaries, till the whole realm be in a

general blaze, which all its island

waters cannot quench, and bonny England

become a holocaust."

|

|

Today the scene couldn't be more

different. It is now a tranquil scene, only broken by

the roar of traffic on its way through the town, and

illuminated at night by countless street lamps,

enveloping the whole area in an orange glow.

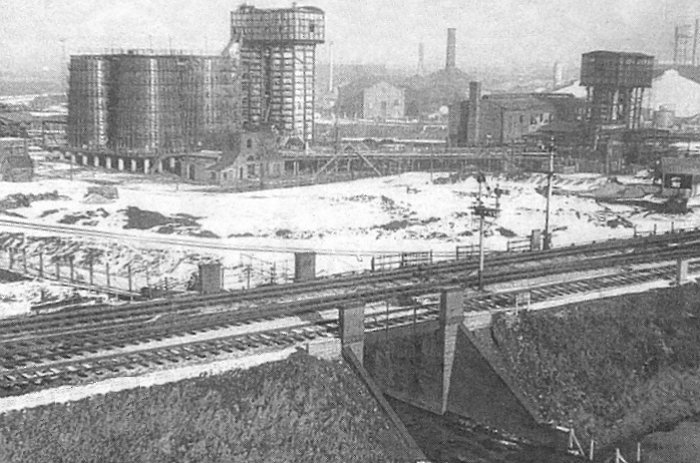

Industrial Wednesbury. From an old

postcard.

|

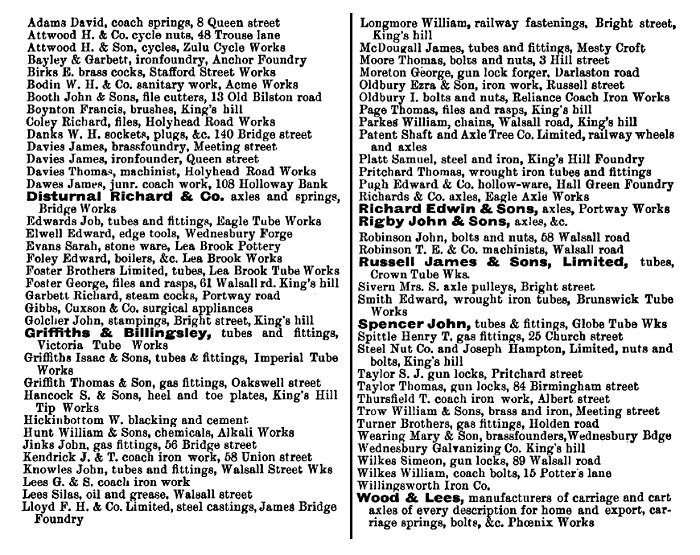

Wednesbury

manufacturing companies, listed in Peck's 1896

to 97 Circular Directory:

|

Iron and

Steel

The earliest references to iron

mining in the area are from 1315 but there are no

records of iron smelting until the 16th

century. Much of the local ore would have been exported

to other towns until the later part of the 18th

century when the growth of local industry provided a new

market. Early iron making used large amounts of

charcoal, and so much of the local woodland would have

disappeared in the process. The locally found iron ore

would have been heated with a large amount of charcoal

in a bloomery, consisting of a hearth of stones, covered

by a dome of clay. A constant blast of air would be

applied using bellows, and a spongy, metallic bloom of

iron would be the result. The bloom would then be

reheated and worked down with a large hammer to remove

some of the impurities (slag and clinker), to make the

iron hard enough for forging. The end product would then

be wrought into bars or rods for the production of

horseshoes, nails or tools.

In 1597 there was a water-powered iron mill (a

forge) owned by William Comberford and leased to William

Whorwood, which is mentioned in the records of the

Quarter Sessions. Two of the employees were Blaise

Uyntam,

a finer, and William Heeley, a hammer man. In

1606 Walter Coleman leased the forge for 21 years. It

had finery and chafery hearths. In 1708 it was owned by

Richard Shelton and leased to John Willetts, who

probably used it as a rolling mill.

|

| In 1726 he is listed as a saw maker. The forge was

possibly at Wood Green and later known as Wednesbury

Forge, owned by the Elwell family and situated at the

confluence of the southern and western branches of the

Tame. The power came from two water sources, which were

dammed, and drove waterwheels from the floodgates. The

wheels would power a large hammer consisting of

a timber beam

bound with iron hoops (the helve), set in an iron pivot

(the hurst). A cast-iron head weighing 7 or 8 cwt would

be fitted to the end of the helve, and this would fall

onto the iron bloom placed on the anvil below. The

hammer was operated by cams and large wooden pegs fixed

in a drum. At intervals the iron would be removed from

the anvil and reheated, the process continuing until it

had been converted into wrought iron.

There were two

types of hearth at the forge, the

finery and the chafery. Both would have burned charcoal

and been fed with air from bellows. In the smaller

finery the lump of iron was re-melted

to produce a bloom; a lump of iron with slag. |

|

The bloom would be hammered to

consolidate the iron and remove much of the slag. It

would then be reheated in the larger chafery and

hammered to draw it out into a bar of various widths and

lengths suitable for blacksmiths, coopers, nail

makers, toolmakers, and wheelwrights.

The chafery would have held several bars at a time,

all in various stages of production. |

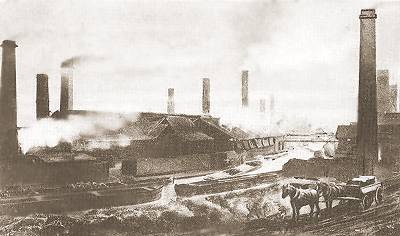

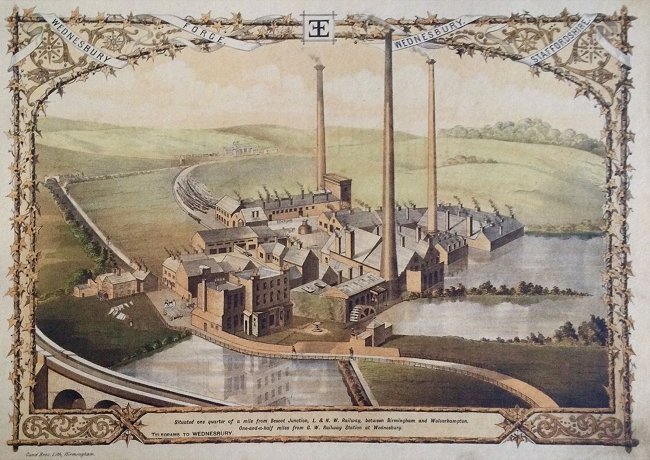

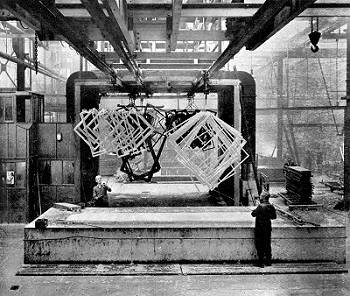

| The Patent Shaft &

Axletree Company at the turn of the 20th

century. |

|

|

In 1675 Frederick de Blewstone from

Germany constructed an experimental furnace in the town,

in an attempt to smelt iron using coal, traditional

charcoal being in short supply. Unfortunately the

attempt failed because of contamination from the

sulphurous gasses emitted by the coal.

By 1785 there were 4 forges in the

town:

| Wednesbury Forge,

Wood Green |

| Adams’s Forge,

Camp Hill Lane |

| Sparrow’s Forge,

Fallings Heath |

| The iron mill at

Wednesbury Bridge |

Adams’s Forge opened in Camp Hill

Lane around 1760 in the middle of the Seven Years War.

The business sold special quality iron to the

government, made from specially selected scrap. As the

forge was situated on the south side of the town, well

away from any natural watercourse, the hammers were

powered by a horse gin. This was superseded by one of

the earliest Watt steam engines in the area, and

supplied with water from a large reservoir extending

from Camp Hill Lane to Camp Street, possibly from a

spring. Unfortunately unhealthy gases arose from the

water and so in 1869 the company moved to Ridgeacre,

West Bromwich.

Sparrow’s Forge was run by Mr.

Edwards in partnership with Edward Elwell, who later ran

Wednesbury Forge. It was situated next to Forge Pool and

Forge Pool Colliery, just off Sparrow’s Forge Road, now

called Park Lane. The forge was initially powered by a

horse gin, and later used water from the adjacent Forge

Pool, which flowed into Willenhall Brook. By 1851 it

became Heath Works, owned by Addison

Russell, and sometime before 1900 the works

closed, and the buildings were demolished.

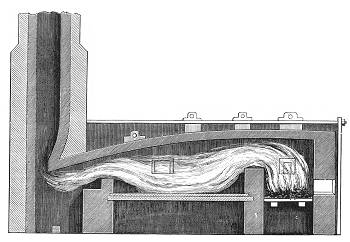

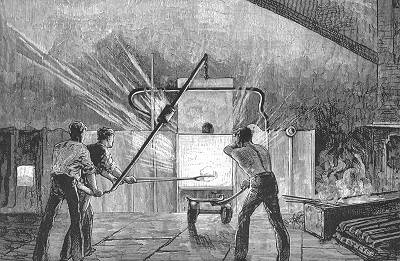

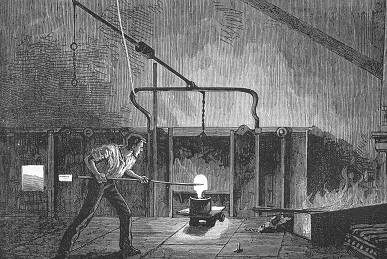

The most common method of producing

wrought iron from pig iron in the 19th century was

puddling, invented by Henry Cort in 1784.

|

|

A section through a puddling

furnace. |

Pig iron or scrap cast iron was melted in a puddling

furnace and stirred with a long pole, which reduced the

carbon content by bringing it into contact with air, in

which it burned.

The puddling furnace heated the iron by reflecting the

exhaust gases from the fire down onto it. In the drawing

opposite, the iron would be placed in the central

section. Because it was not in contact with the fire,

cheaper, poor quality fuel could be used. After puddling

the iron was hammered and rolled to remove the slag. |

| The iron mill at Wednesbury Bridge opened in the 17th

century and may have been built by William Comberford,

who planned such a mill in 1606. In 1761 the buildings

were owned by John Wood, the son of ironmaster William

Wood who lived at the Deanery in Wolverhampton. |

| John obtained a patent in 1761 for making malleable

iron from pig iron. He also melted selected scrap, and

produced iron that was as good as the best Swedish iron

of the day, often being used by the local gun barrel

makers. In 1816 the works included a lift hammer, a tilt

hammer, and sufficient warehouses for storing scrap, and

finished iron. According to F.W. Hackwood, John lived

“in great splendour” in the town, and was buried there

after his death in 1779. |

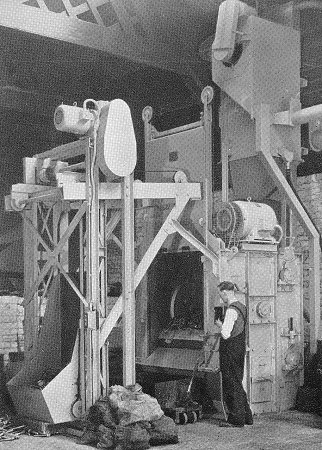

Puddlers at work. |

|

The first coke furnace in the town

was at Hallens’ Ironworks, which stood by the canal on

part of the site later occupied by the Patent Shaft

Steelworks. The following description of the works is

from Aris’s Gazette of 6th January, 1800:

A capital set of ironworks,

consisting of a blast furnace, foundry, boring mill,

forges, slitting and rolling mills, pattern and smiths

shops, warehouses, six workmen’s houses and every

suitable convenience for carrying on a very extensive

trade, advantageously situated on the banks of the

Birmingham Canal at Wednesbury: the whole comprising of

about two and a half acres of freehold land with

valuable mines of coal, ironstone and clay under the

same; together with all the machinery, implements and

tools now on the premises.

By 1830 there

were only two furnaces in the town that were used for

iron smelting, which is surprising considering that

large amounts of iron ore were mined locally. The first

was Matthews and Company who ran Broadwaters Furnaces.

They had 2 furnaces which produced 6,368 tons of pig

iron in 1830. The second was Lloyds and Fosters at Old

Park Iron Works. In 1823 they had one furnace which

produced 2,600 tons of pig iron in 1823, and in 1830

there were two furnaces producing 5,280 tons of pig

iron.

|

|

Tapping a puddling furnace. |

Marshall & Mills who ran Monway

Iron Works produced the best gun barrel iron in the

world. Their customers included the Birmingham gun

makers, and the British and American governments. By

1844 their iron sold for £44 a ton.

Also in the 1840s Adams & Richards of

Bridge Street were producing coach springs. |

| |

|

Read a report from 1843

about

the employment of children in

the town |

|

| |

|

|

White’s

directory of Staffordshire from 1851 lists the following

iron and steel companies in Wednesbury:

|

George Adams & Company,

Camp Hill Lane |

|

John Bagnall & Sons,

Imperial Works, Leabrook |

|

Colburn & Groucett,

Broadwaters |

|

Fletcher, Rose & Company,

Victoria Works, Leabrook |

|

Lloyds, Fosters &

Company, Old Park Works |

|

John Marshall, Monway

Iron and Steel Works, Leabrook |

|

Maybury & Williams,

Leabrook |

|

David Rose, Moxley Forge |

|

Addison Russell, Heath

Works |

|

Thomas Wells, Moxley Iron

& Steel Works |

Others included

Gospel Oak Ironworks owned by Philip Williams & Sons,

Brunswick Iron Works, owned by Henry Pitt, and Bull's

Bridge Ironworks owned by Molineux & Company.

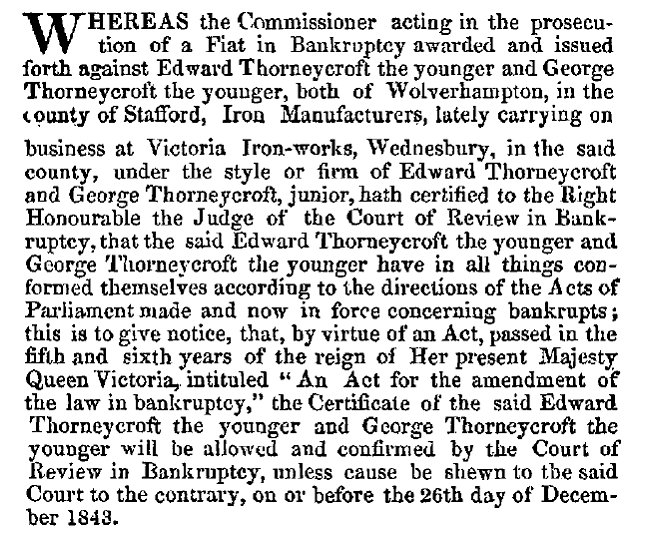

The Victoria

Ironworks at Leabrook were run by the Thorneycroft

brothers, Edward and George Bernard Thorneycroft, who

also ran Shrubbery Iron Works in Wolverhampton. Their

business in Wednesbury was declared bankrupt, as can be

seen from the notice below. The factory was then

acquired by

Fletcher, Rose & Company

and in 1852 by the Patent Shaft and Axletree Company.

From the London Gazette, 5th

December, 1843.

Most of the

early iron and steel works closed as a result of the

depression of 1875 to 1886 after which the main players

were the Old Park Works, the Patent Shaft, and F.H.

Lloyd at James Bridge Steel Works.

Wednesbury had

many foundries including:

|

John Deyrick, established

in 1818 |

|

Addenbrooke & Lloyds

Fosters, established in 1829 |

|

Edward & John Blakemore &

Company, brass and iron, Camp Street |

|

J.H. Blakemore, brass &

iron. Trouse Lane |

|

Thomas Elwell, Bull Lane |

By the 1850s

Wednesbury had secured a monopoly of the new iron tube

trade and had become the largest local supplier of iron

to the railways.

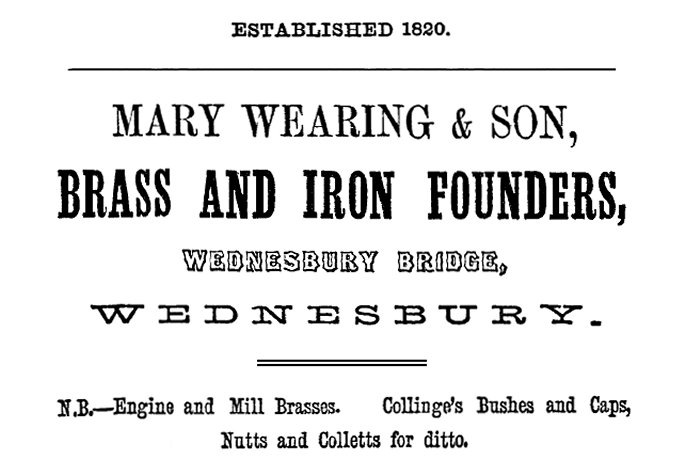

An advert from 1861.

Wednesbury Forge

Wednesbury Forge

was leased by Edward Elwell in 1817 and purchased

by him in 1831. His father, William Elwell, an

ironfounder at Walsall, became Mayor of the town in 1778

and 1787. Edward trained as a surgeon and served with

the Royal Artillery from 1807 to 1811. After returning

to Walsall and practicing there for a while he set

himself up as a maker of edge tools at Sparrow’s Forge

in Wednesbury.

Elwell's Pool and Forge.

|

|

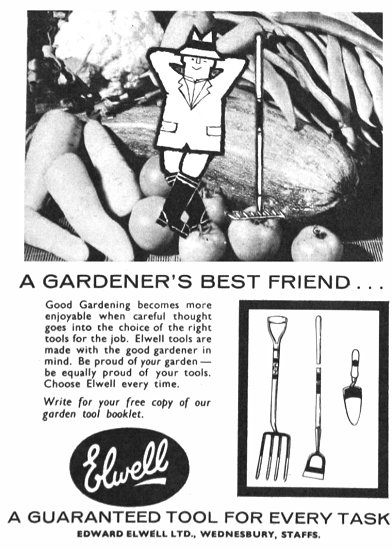

An advert from 1949. |

The Elwell family had another

industrial link with the town because Edward’s uncle,

Edward Elwell established an ironworks in Wednesbury

producing cast iron holloware. It later became Hill Top

Foundry.

| |

Read about

Hill Top Foundry |

|

|

In 1831 Wednesbury Forge consisted

of a forge or iron mill, a grinding mill which had

previously been a windmill, 2 mill pools covering 25

acres, with a watercourse, a house and 13 cottages,

which were previously workshops.

The machinery at the

forge was driven by steam and water power, and the water

rights provided a worthwhile income from the canal

company and other local firms. By 1851 management of the business

had passed into the hands of Edward’s son, Edward

junior.

|

Unfortunately Edward junior died prematurely and so

his father, now elderly, resumed control of the business

until his death in 1869.

During the American Civil War (1861 to 1865) the company

sold large quantities of edge tools to America, greatly

benefiting from the war, and also exported its products

to many countries. The company's catalogue listed over

1,200 types and sizes of heavier hand tools, such as

axes, forks, hoes, pick axes, shovels, and spades. By

1889 there were around 200 employees. |

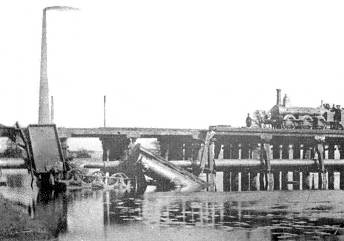

A railway accident at Elwell's

Pool in 1859. |

Wednesbury Forge. From the 1869 Elwell

catalogue.

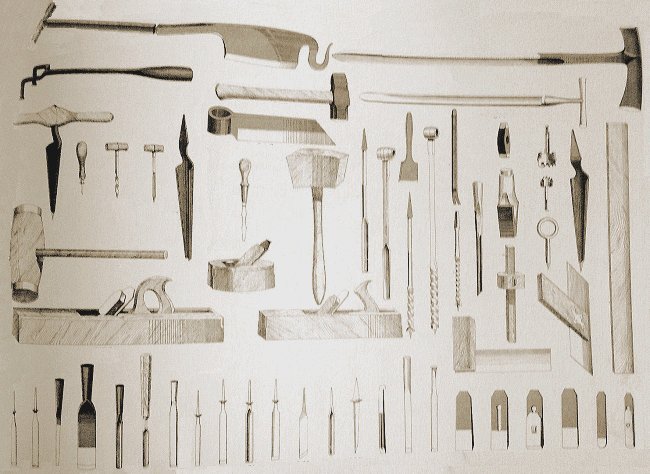

Elwell tools from the 1869 catalogue.

More Elwell tools from the catalogue.

More of the wide range of Elwell tools

made in the 1860s.

|

An advert from 1962. |

Edward Elwell never recovered from

the death of his son and became a sad and morose man. He

helped to establish St. James’ Church and a school for

the children of his workmen. After his death Alfred Elwell, a grandson, took over the running of the

business, and on his death in 1902 it became a private

limited company. Two years later the water wheels were

replaced by water turbines.

Around 1930 Edward Elwell Limited and

the Chillington Tool Company of Wolverhampton combined

and formed a holding company; Edge Tool Industries

Limited, and in 1937 the firm displayed a range of tools

at the British Industries Fair, including agricultural

tools, axes, billhooks, choppers, cleavers, earth

borers, edge tools, forks, foundry ladles,

hammers, hatchets, hoes, horticultural tools, matchets,

picks, road contractors' tools, shovels, spades, and

slashers.

In 1962 Eva Industries acquired

Edge Tool Industries Limited, and in 1967 Spearwell

Tools was formed to merge the gardening and agricultural

interests of Spear and Jackson and Eva Industries. |

|

Spearwell Tools was jointly owned by the 2 companies,

but after several years of losses, Spear and Jackson

acquired the whole group, taking over Wednesbury Forge

in 1970. In 1995 the company became Spear and Jackson

plc.

Wednesbury Forge continued to

produce tools until Christmas 2005, when the factory

closed. The administrative, warehousing and maintenance

sections continued to operate throughout part of 2006.

In 2007 the buildings were demolished, and the site

cleared.

A company letterhead.

A close up view of the factory from the

above letterhead. On the left is the Elwell family's house.

|

| |

|

| Read about Old

Park Works and The Patent Shaft & Axletree Company |

|

| |

|

|

|

|

Read about

Britain's largest foundry -

F. H. Lloyd & Company Limited |

|

|

|

|

|

| |

|

|

Read about Crown Tube

Works and Tube Making |

| |

|

| |

|

|

Read about Richard

Garbett and the Monway Gas, Steam and Water Cock

Manufactory |

| |

|

|

|

|

Read about John

Bagnall & Sons at Lea Brook |

| |

|

An advert from 1851.

An advert from 1861.

|

In the 1860s Josh. & Thos. Davies

manufactured a wide range of products, including high

and low pressure steam engines on the vertical direct

action, beam and horizontal principles, steam donkeys

for feeding boilers, improved metallic pistons and

safety valves without stalk or guide, winding and

pumping machinery, and brakes for collieries, hydraulic

presses, lift and force pumps by hand or power, portable

mounted steam threshing machines, improved water heaters

by waste steam, blowing fans by hand or power, hoisting

crabs and cranes, circular saw and rack benches,

shearing and punching presses, pipe fittings, nut and

bolt screwing machines, forge hammers, and boring and

grooving machines for coach axle work, sluice glan plug,

valve and other cocks, lathes, carriage shafting,

pulleys and couplings, etc. The firm also carried out

turning, boring, planing, fitting, shaping, and repairs

done to order.

The firm's small steam engines were

as follows: |

|

Other

Companies and Products

Henry Hope

& Sons Limited. Windows

|

|

An advert from the early 1960s, |

The company started in 1818 in

Birmingham and started to produce metal casements in

1819. In between 1845 and 1857 they made all of the

windows for the Houses of Parliament, and by 1900 their

main product was metal windows.

In 1904 the company purchased some

land at the corner of Dartmouth Road and Halford's Lane,

Smethwick and in 1905 built the Halford Works. In 1919

the whole business was transferred there, and by the

late 1950s the factory covered around 10 acres.

The company acquired a 37 acre, old

coal mining site in Wednesbury in 1938 and built a new

works there which included a hot dip galvanising plant.

The plant included a 120 ton bath of zinc at a

temperature of 852 degrees Fahrenheit.

|

| By 1957 Hopes made over 500 types and sizes of

windows and installed a specially designed, highly

mechanised galvanising plant at Wednesbury for the

production of reversible steel windows for multi-storey

flats. The company had a large export market and in

1965 merged with another metal window manufacturer, the

Crittall Manufacturing Company Limited of Braintree to

form Crittall-Hope Limited. Braintree then became the

new company's headquarters. |

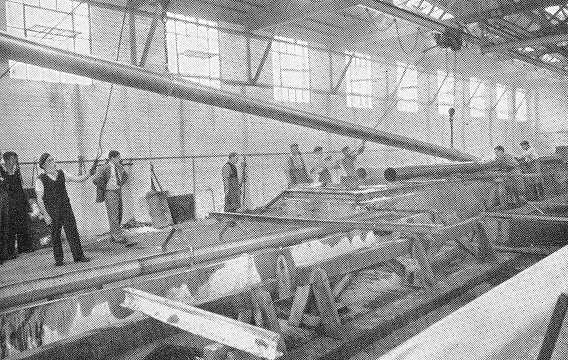

The hot dip galvanising tank. |

Hope's assembly and storage department.

Part of Hope's mechanised galvanising

plant.

| |

|

|

Read about William

Mills Limited, producer of accurate aluminium castings |

| |

|

| Read about Wednesbury's

electrical equipment manufacturers:

William Sanders, and The

Power Centre. |

|

| |

|

|

An advert from 1851.

An advert from 1865.

An advert from 1896.

|

| Crown Metal

(Wednesbury) Limited Crown Metal

(Wednesbury) Limited was founded in 1919 by W. G.

Hitchman, and became a limited liability company in

1952. At the time, the Managing Director was the

founder's son. The non-ferrous foundry used a range

of alloys including brass, gunmetal, phosphor

bronze, and high tensile alloys of aluminium bronze,

and manganese bronze. Alloys were also made to

individual customer's requirements. Castings were

supplied to many industries including

manufacturers of machinery, hydraulic equipment,

electrical equipment, and ship builders, varying in

weight from a few ounces to five hundredweights.

They were supplied in small or large quantities as

required. The firm prided itself in its quick

service, especially when castings were needed for

plant maintenance. |

An advert from 1954.

| J. Frankel

(Aluminium) Limited First class aluminium

alloys were produced in Wednesbury by J. Frankel

(Aluminium) Limited at Victoria Works, Alma Street.

The company was incorporated on 17th January, 1948.

Before the year was out the firm began to refine

aluminium on the site of the former Globe Ironworks

in Charles Street, Walsall. By 1974 the factory was

producing aluminium alloy ingots from scrap, for use

in foundries, rolling mills, and steelworks. In May

1977 some of the firm's buildings in Bridgeman

Street, Walsall were sold to the South Staffordshire

Waterworks Company for £105,000.

Unfortunately the company only had a short life.

The following notice appeared in the London Gazette

on 8th October, 1982:

|

J. Frankel

(Aluminium) Limited

At an

extraordinary general meeting of the

above named company, duly convened,

and held at the Holiday Inn, ATV

Centre, Birmingham, on 15th

September 1982, the subjoined

extraordinary resolution was duly

passed:

That it has

been proved to the satisfaction of

this meeting that the company cannot

by reason of its liabilities

continue its business, and that it

is advisable to wind up the same,

and accordingly that the company be

wound up voluntarily, and that

Bernard Phillips, of New Cavendish

House, 18 Maltravers Street, London

WC2 R3EJ and David Zackheim, of 48

Welbeck Street, London W1M 7HE, be

and they are hereby appointed joint

liquidators for the purpose of such

winding-up. |

|

|

An advert from 1954.

|

Roberts & Company (Wednesbury) Limited The

firm, based in Franchise Street, was founded in 1919

and became a limited liability company on 22nd

August, 1931.

It specialised in the production of galvanised

steelwork for overhead electrical transmission

lines, carried on wooden poles.

The firm had a large, well-equipped forge and

bending shop where special steelwork of all kinds

was produced including motor body parts, hinges, tow

bars, towing brackets, and signal ladders for

railways.

The firm also specialised in flame-cut and welded

fabrications.

Unfortunately the business, like many others,

suffered during the recession in the 1990s. The

company went into receivership on 17th May, 1993,

and went into voluntary liquidation on 31st January,

1998. |

An advert from 1954. |

|

The text above and the advert

below were taken from the 1918 Wednesbury Official

Handbook. |

An advert from 1954.

An advert from 1956.

An advert from 1958.

An advert from the mid 1950s. Courtesy of

Christine and John Ashmore.

An advert from 1958.

|

The text above and the advert

below were taken from the 1918 Wednesbury Official

Handbook. |

|

Quilliam

Limited. Jute Bag Manufacturers

|

|

An advert from the early 1960s. |

Quilliam Limited manufactured all kinds of jute

sacks and bags for industrial use at Victoria Works,

Potter's Lane.

They produced new and reconditioned sacks for all

types of small metal components, steel strip and wire,

nuts, bolts, nails, washers, rivets, stampings,

castings, and chains.

The factory survived until the early 1960s when it

was destroyed in a disastrous fire. |

| |

|

| Read about Edwin Richards &

Sons who made coach axles, springs, and fittings. |

|

| |

|

|

Another local company,

with a similar name, supplying the same range of

products as Edwin Richards & Sons was based in

Hobbins Street, off Portway Road. This advert is

from the 1909 Ryder's Annual.

The Ordnance Survey map from

that time does not show any obvious factory in

Hobbins Street, only houses. There were more

sizeable buildings at the the ends, fronting on the

Holyhead Road, and in Portway Road, but that is all.

It could be that Richards &

Company were suppliers of Edwin Richards & Sons'

products, and possibly run by a member of Edwin

Richards' family. |

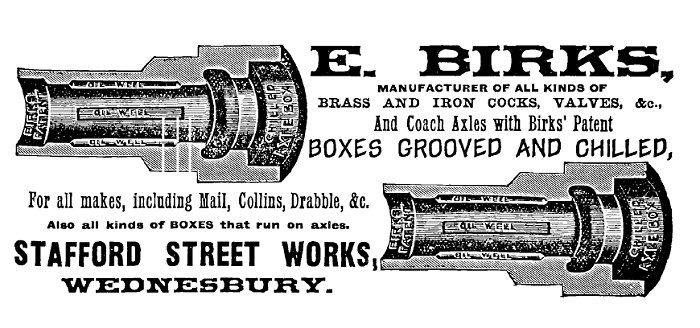

Another coach axle manufacturer. The

advert is from 1861.

|

Another advert for John

Rigby & Sons who were based at Phoenix Works.

This advert is from 1896. |

| Wednesbury also had at

least one cycle maker.

S. J. Taylor is listed in Peck's 1896 Trade

Directory of Birmingham. The address given is Apsley

Place, Pritchard Street, Wednesbury.

The advert opposite is from

Ryder's Annual, 1911. |

|

|

The advert opposite is

from the 1909 edition of Ryder's Annual. |

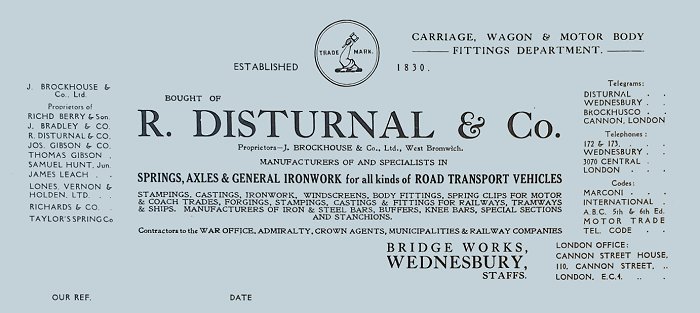

Richard Disturnal & Company also

produced axles. The advert is from 1896.

|

From the 1918 Wednesbury

Official Handbook. |

|

|

|

|

Two

adverts from 1918.

A letterhead from

1924. |

|

|

Hickinbottom's Bakers

Many people will fondly remember

Hickinbottom's excellent bread, baked in the Albert

Street bakery and delivered door to door by expert

roundsmen.

The business started in 1893 when Sam Hickinbottom, a wheelwright at the Patent Shaft and

Axletree Company was on short time, and couldn't find

alternative work. His wife Martha had previously worked

as a domestic help at Priddins Bakers in Bridge Street,

where she learned the art of bread making. Because of

their financial hardship, the young couple decided to

establish their own bakery.

They rented a shop with a small

bakehouse in Lower High Street, opposite the Board

School and began to bake and

sell bread. Sam realised that the best way to sell their

bread was to take it around the local area. He began by

selling bread to his ex-workmates, delivered in a small

basket. He soon acquired a hand cart. Sales were good

and so the Hickinbottoms acquired a pony and cart.

|

|

An impression of

Hickinbottom's first shop in Lower High

Street. |

|

Within a short while the business

moved across the road into larger premises with a new bakehouse. Martha soon became pregnant and had the job

of bringing-up her first son Joe, followed by two others

Bert and Len. Sam then employed a baker and was able to

greatly increase the product range.

Early success encouraged him to purchase a pony and

cart but such was their financial position that this was

sometimes hired out when not required for the

Hickinbottom business. The income from this hiring

helped to feed the pony.

As business increased an

opportunity arose to move to better premises. The owner

of a business opposite their shop offered to build a

small new bakehouse onto the existing building in return

for them signing a seven year lease. Sam and Martha

seized this opportunity and Sam further increased the

facilities by building a small stable for the pony and a

covered area for loading.

By the time the seven year lease

had expired the Hickinbottoms had three sons, Joe

(1893), Bert (1897) and Len (1901) and when old enough,

the boys helped in the business by delivering bread in

three wheeled baskets. Despite this help, Sam did not

usually finish work on a Saturday until between 8pm and

9pm. |

|

|

In 1906 at the age of 13, Joe started

classes in shorthand, typewriting and book-keeping and

began work at Stockdale and Sargent, solicitors, in

Lower High Street. The Senior Partner wanted Joe to take

Articles and become a lawyer, but instead he took his

father's offer of joining the family business.

The business became extremely successful. By the

First World War, Sam had been joined by his three sons,

and had moved into a larger premises in Victoria Street

with better facilities, including two Cornthwaite ovens.

Only the best ingredients were used including top grade

flour from Rank's Flour Mills. The bread

gained a deserved reputation for high quality.

During the war the business thrived because other

foods were in short supply and so the demand for bread

greatly increased. By this time Joe was going out with

Annie Lett of Tipton, whom he had met at Camp Street

Sunday School. She later became his wife and was recruited into

the business to take charge of a horse and cart to help

with deliveries. |

|

The firm soon outgrew the Victoria Street premises

and so a larger bakery was built nearby in Victoria

Street. It included a lot of second-hand equipment from

Birmingham bakeries, and opened in June 1923. The

employees even hauled 30,000 glazed bricks for the

building, to the site, after normal working hours. The

second-hand equipment was slowly updated, and the firm

acquired its first motorised van and a large horse-drawn

flat wagon to transport 25 tons of flour weekly, from the nearby GWR goods

depot to the bakery. The second hand equipment was

gradually updated. Sam died in 1939 and his eldest son Joe became

Managing Director.

In 1951 Hickinbottoms joined Allied Bakeries of

London, makers of Sunblest bread. By 1960 the Victoria

Street bakery supplied around 30,000 customers, and it

became essential to extend the bakery in order to cope

with increasing demand. The Hickinbottom brothers stayed

in control of the Wednesbury operation, Joe as Managing

Director, Bert as Transport Director, Len as Sales

Director and Bert's son Geoffrey as Sales Manager.

The firm decided to build a new bakery at Wednesbury

and if possible acquire the area around the existing

bakery so that the new bakery could link-up with the

existing buildings. Over the next two years Bert

Hickinbottom set about purchasing adjoining properties, which were

demolished to make way for a new bakery.

In 1961 the family lost two members

from the second generation, Bert and Len. Third

generation Geoffrey was appointed Managing Director and

his cousin Michael, Director, and second generation Joe

became Chairman.

Building work soon got underway and the

new Electric Bakery in Albert Street opened in May 1963.

At the time the bakery supplied around 30,000 retail

customers, 800 wholesale customers, and employed 180

people. The company operated eighty vehicles and had its

own maintenance department.

Michael Hickinbottom soon became Chief Executive of

the group, leaving Geoffrey in charge of the operation

at Wednesbury. In 1977 Geoffrey decided to retire to

Norfolk. At the time there were 600 employees and well

over 200 vehicles at the Wednesbury site. Soon the Hickinbottom name ceased to be used

and door to door deliveries were

discontinued. The Wednesbury bakery closed in 1989 and

production was transferred elsewhere. Demolition of the

bakery soon followed, to make way for the Mecca Bingo

Club, which stands on the site today. |

|

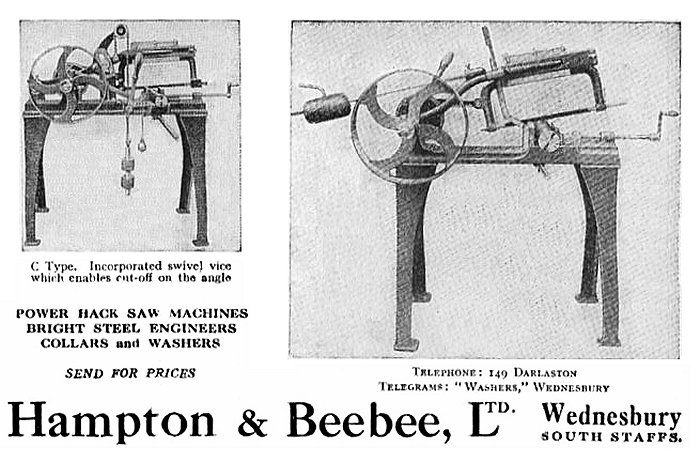

The Steel

Nut & Joseph Hampton Limited. Fastenings, Steel Bars,

Tools |

| The Steel Nut & Joseph Hampton Limited made a wide

range of products at their Fallings Heath works. As well

as nuts, bolts, set screws, and studs they produced a

wide range of bright drawn steel bars, and tools,

including vices for wood and steel, clamps, dowelling

jigs, holdfasts, and wood planes. In 1955 the company

produced its patented quick release screw vice. The

factory was known locally as "the Woden". For

a detailed history look at the

Darlaston industry

section on this website. |

|

|

|

|

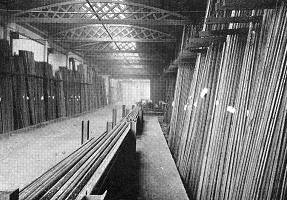

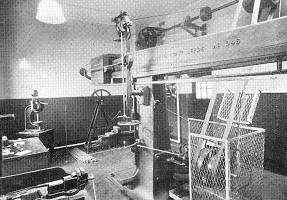

Two views of the

Steel Department. |

|

The Steel Store. |

|

The Test House. |

Another nut and bolt manufacturer. The

advert is from 1861.

Another nut and bolt maker in 1861.

| |

|

| Read about

Samuel Platt Limited based at King's Hill

Foundry. |

|

| |

|

| Read about

Prodorite Limited.

A well known and

important manufacturer. |

|

| |

|

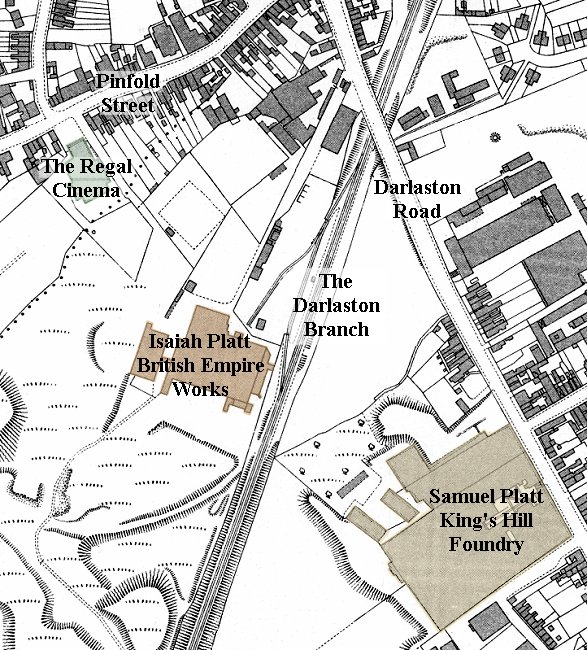

| Isaiah Platt Limited

The location of

Isaiah Platt's British Empire Works.

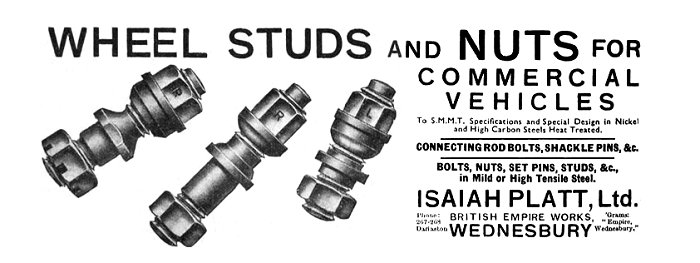

An advert from

1938.

| The

following

description is

from his

obituary,

produced by the Institution of

Mechanical Engineers in 1931. Isaiah

Platt, O.B.E., who was born in

1860, was the youngest son of the late

Mr. Samuel Platt, founder of the

firm of Messrs. Samuel Platt, King's

Hill Foundry, Wednesbury, with whom he

served his time from 1876 to 1881. He then entered the drawing office,

of which he was given sole charge in

1886, and subsequently became a partner.

In 1918 he severed his connexion with

the firm and established the firm of

Messrs. Isaiah Platt of Wednesbury,

where he built up a most successful

business. Mr. Platt was 71 years of age at the

time of his death which occurred on 1st

August 1931. He had been a Member of the

Institution since 1903. |

|

| Isaiah Platt Limited was

established 1919. It had a

capital £50,000 and employed

200 people. The directors

were: Isaiah Platt, O.B.E. (Governing), W. G. Berry

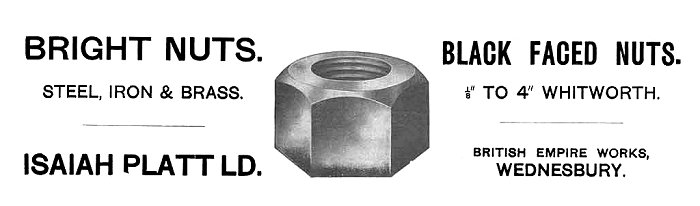

(Managing) and H. W. Wilson.

Manufactures. The firm specialised in bright steel bolts,

set-screws, studs, bright and

black faced nuts, bright drawn steel in

rounds, hexagons and squares. |

An advert from

1921.

An advert from

1928.

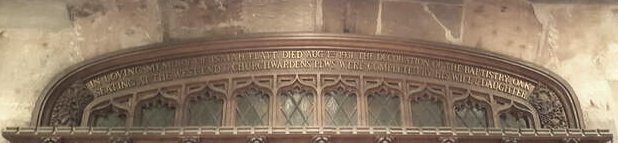

The Platt

memorial.

There is a memorial to Isaiah Platt

in the Choir Vestry at Saint

Bartholomew's Church in Wednesbury. It

reads as follows:

In

loving memory of Isaiah Platt, died Aug

1st 1931. The decoration of the

Baptistry, Oak Seating at the West End &

Churchwardens’ Pews were completed by

his wife & daughter.

|

|

|

|

|

Two adverts

from 1949. |

| There were several galvanisers in the town

including Frost & Sons of Falcon Works, Church

Street, Moxley which specialised in galvanising

electricity transmission towers for the Central

Electricity Board, and galvanising every kind of

wrought and cast iron work, and tubes and

fittings. The company had a reputation for quick

service, high quality work, and low prices. |

|

|

|

|

An

advert from 1954. |

|

A shot

blasting machine. |

|

Galvanising tubes,

forty feet long and eleven inches in

diameter.

|

The text above

and the advert below were taken from

the 1918 Wednesbury Official

Handbook. |

|

Frost & Sons (Moxley) Limited

was founded in 1889, and initially

specialised in tube and general

galvanising. There were two

branches, one at Rough Hills,

Wolverhampton, and another at Ebro

Works, Tividale, Tipton, which

specialised in galvanising bolts,

nuts, and washers etc. by

centrifugal force. The business was

wound-up in March 2002. |

Wednesbury, like many other local town had its

share of brick makers. The very last one was

Hadley (Wednesbury) Limited, based at Brunswick

Park Brickworks in Crankhall Lane.

Hadleys started producing bricks in 1876, and

by 1950 150,000 bricks were leaving the factory

each week. Production ended in about 1960 when

the business closed. Another long-standing

Wednesbury business was Isaiah

Oldbury Limited, founded in 1861 to

manufacture coach and cart axles at

the Reliance Coach Ironworks.

The

founder, Isiah Oldbury, J.P. born at

Wednesbury in May, 1840 was Chairman

of the Wigmore Schools Management

Board, a Borough Magistrate, a

prominent member of the Liberal

Party, a Wesleyan Methodist, and

Mayor of Wednesbury in 1896 to 1898. |

An advert from 1949. |

|

Councillor

Isaiah Oldbury in his mayoral robes. |

The firm was a pioneer in the

development of trailer undergear,

and opened a factory in West

Bromwich for the production of axles

and drop-forgings. The firm had

its own malleable and grey iron

foundry, a spring shop, and a

machine shop for the production and

supply of general machined parts.

The factory was complete with a

range of drop stamps, drop hammers,

and machine tools.

Trailer axles and components were

regularly exported to much of the

world, including Rhodesia, where the

firm built-up a large export market

in heavy cart axles.

The many products included roller

bearing hubs, internal expanding

brakes, brake fittings, towing

couplings, drawbars, jockey wheels,

steel wheels, springs and fittings.

Large numbers of specially designed

chassis were supplied to

manufacturers of caravans, portable

welding compressors, and vacuum

plant.

In 2000 the company was acquired

by Skan Group Holdings and moved to

its present 2½

acre site in Wobaston Road,

Wolverhampton. |

| From Wednesbury

Faces, Places and

Industries, published in

1897: The Reliance

Coach Ironworks, owned by

the present Mayor, Mr.

Isaiah Oldbury occupy a high

and influential position in

this important branch of

manufacturing activity. It

is about twenty three years

since the present works were

started, and thirty three

years since the business was

founded by Mr. Oldbury. Its

very successful career from

the inception to the present

time abundantly testifies to

the energy and ability

brought to bear upon its

management. The works have

been enlarged from time to

time to meet the increased

demands, and only recently a

malleable iron foundry has

been added.

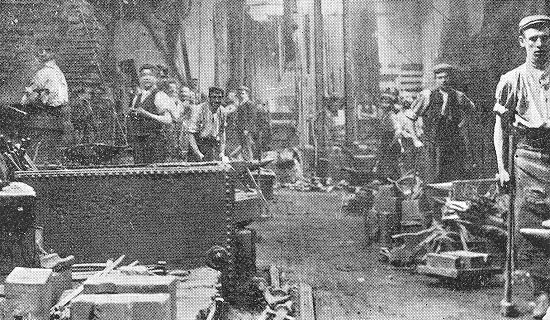

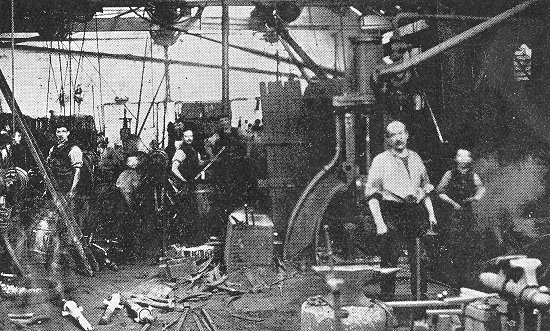

The Smithy.

They now

cover a considerable area of

ground, giving constant

employment to between one

hundred and fifty and two

hundred hands, and being

equipped with all the

requisite steam power

machinery and labour-saving

appliances to facilitate

rapid and economical

production. The chief

manufactures include coach

bolts and nuts, steps,

scrolls, dash irons, clips,

shackles, and coach ironwork

in general; also mail,

Collinges, drabbles, and

other axles, and springs.

Axle and turning shop.

For all

these productions Mr.

Oldbury enjoys a high

reputation both at home and

abroad, hence his large and

steadily increasing

connections; and it may be

stated that he is a

well-known contractor to Her

Majesty's Government, the

War Office, and Admiralty;

also to Sir W. G. Armstrong,

Mitchell and Co., Limited,

and Sir Joseph Whitworth and

Co., Limited. None but the

most durable and best

finished goods leave the

premises, whilst the

productive facilities are

such as to ensure the speedy

execution of all orders. |

|

An advert from 1954.

An advert from 1916.

M. H. Lowe Limited were one of the

oldest engineer's merchants in the

Midlands. The shop in Union Street

was a delight for anyone interested

in tools.The business was

registered on Saturday, January 4,

1947 but is now dissolved.

The firm specialised in all kinds

of engineer's supplies and equipment

for local companies, and carried

comprehensive stocks of all

reputable makes of tools. They were

the sole agents in the West Midlands

for 'Lion' brand 'G' clamps and

strap clamps, and were stockists and

technical advisers for 'Universal'

grinding wheels. Nuts, bolts, and

Allen screws were also stocked, as

well as drill chucks, pipe tools,

and precision measuring tools. |

An advert from

1954. |

|

An advert from

1954. |

The housing shortage after World

War 2 led to the construction of

many pre-fabricated houses which

were relatively cheap, and fast to

build.

Mr. H. Howard-Smith developed a

method of building

traditional-styled brick houses

quickly, by assembling factory-built

components. S. J. Smith (Bidford)

Limited was founded

to mass-produce the components, and

to build the houses in record time.

The company Chairman was Mr. H.

Howard-Smith, and the Managing

Director was Mr. S. J. Smith.

Using the Smith system, a house

could be built in half the normal

time. By the mid 1950s the firm had

built over four thousand houses in

the Midlands, at a rate of one

thousand a year, and with a labour

force of less than 500 men.

It was extremely difficult to

distinguish the houses from those

built using traditional methods. |

|

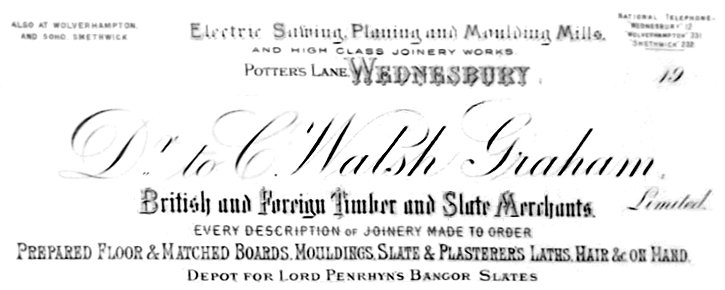

A once

familiar sight in Potters Lane was

C. Walsh Graham's timber yard. The

text opposite and the advert below

were taken from the 1918 Wednesbury

Official Handbook. |

|

The text above

and the advert below were taken from

the 1918 Wednesbury Official

Handbook. |

|

The Chance and

Hunt chemical works at Wednesbury.

An advert from

1954.

|

The text above and the

advert below were taken

from the 1918 Wednesbury

Official Handbook. |

|

|

The text above

and the advert below were taken from

the 1918 Wednesbury Official

Handbook. |

|

|

|

|

Two

adverts from 1918. |

|

|

|

|

|

|

|

Return to

Growth |

|

Return to

the contents |

|

Proceed to

Education |

|