|

Coal

Mining

Willenhall stands on part of the

South Staffordshire coalfield, where the middle coal

measures are found, known locally as the ten yard seam.

It forms a gently folded shallow syncline that outcrops

in a wide arc from Dudley through to Darlaston and

Willenhall, and consists of 12 to 14 closely overlying

seams, giving the appearance of a single bed of coal. It

is usually less than 400 feet below the surface, and in

many places can be found just a few feet underground.

The coal measures also extend south

westwards towards Bilston and Wolverhampton, and north

eastwards towards Bentley. The geology on the northern

side towards Wednesfield is quite different. It consists

of a dolerite sill, with mudstones, and sandstones to

the north.

Coal became an essential raw

material for the developing industries in the Black

Country, particularly for iron and steel making, and the

expanding railway network. As a result many parts of the

area were heavily mined, and large numbers of people

moved into the town to work in the mines.

There were a number of deep mines,

which employed many people, often excavating sizeable

caverns underground to fully exploit the 10 yard seem.

Columns of coal were used to support the roof instead of

wooden props, and so many tons of coal must have been

lost in this way. |

|

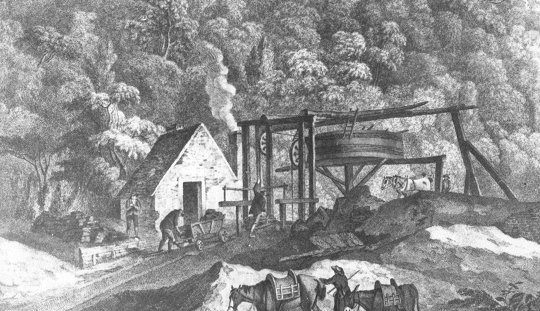

A typical bell pit. |

Most of the mines were simple bell

pits, in which a central shaft was dug down to the coal

measures, and widened at the bottom as coal was removed.

As much coal as possible was removed until the roof

showed signs of collapse, at which time the pit would be

abandoned, and a new replacement dug nearby.

As a result, much of the mining

land was covered in abandoned bell pits, and in the

course of time consisted of a pattern of hollows,

separated by small spoil heaps. Each hollow was above an

old shaft, which sometimes filled with water, to form a small pool.

Some of the pits, called gin pits,

had horse-driven winding gear at the top of the shaft.

They were a common sight in the Black Country. |

| Pits were dug in much of the land that surrounds the

town centre. Many were to be found around Moseley,

Portobello, Little London, Lane Head, Short Heath, and

New Invention. Portobello grew as a result of the brick

making industry, but soon turned into a thriving mining

community as large numbers of people moved into the

area. It became covered with tiny back-to-back houses,

surrounding courtyards with shared toilets, and washing

facilities. Lane Head and Sandbeds were small hamlets

until they were expanded to cater for the thriving mining

community. |

A map showing the approximate

location of some of the mine shafts in the Willenhall

area. In reality there would have been many more,

because large numbers of small pits were never recorded. |

| Mining in Willenhall got off to a late start

compared with neighbouring towns, because much of the

coal was to be found on land belonging to the Deanery

and the Prebends. In 1811 the Reverend Edward Legge,

Dean of Wolverhampton obtained statutory powers to grant

leases for coal mining on church-owned land. Each of the

small pits, which dominated the area, was run by just a

few men who became known as 'butty colliers', or 'butties'.

Some of the larger collieries were New Priestfield

Colliery, off Bilston Lane, owned by William Ward & Son,

and linked to New Priestfield Iron Works, and the

Birmingham Canal by a tramway. Moseley Hole Colliery,

near Moseley Road, was named after the De Mollesey

family of Bilston, and run by the Chillington Iron

Company. Osier Beds Colliery, near Moseley Road was so

named because of the 'osier' willow trees which covered

the area, and were used for basket making. Beacon Hill

Colliery, which stood near to Beacon Road was owned by

J. Brewer of New Invention, and linked to the Wyrley &

Essington Canal by a tramway, later used by the nearby

Short Heath Colliery.

Others included Bunker’s Hill

Colliery, off Bunkers Hill Lane, Merrill’s Hole

Colliery, Bull Plack Colliery, and Trentham Colliery,

all off Noose Lane, and Willenhall Colliery off Stringes

Lane, owned by Fletcher, Solly & Urwick Limited, which

owned Willenhall Furnaces.

The following is a list of working coal mines in

Willenhall in 1869 and 1870:

|

Colliery |

Owner |

Colliery |

Owner |

|

Albion |

Harper and

Company |

Nimmins |

Dodd and

Southan |

|

Anson |

Earl of

Lichfield |

Noose Lane |

Bate and Son |

|

Barr Croft |

J. Hill and

Company |

Pool Hayes |

Pool Hayes Colliery Co. |

|

Bomans Harbour |

H. B.

Whitehouse |

Pool Hayes |

Samuel

Fenn and family |

|

Boltoney Bay |

J. Yardley and

Company |

Pool Hayes

Meadow |

Chillington

Iron Company |

|

Bull Pleck |

Messrs

Groucott |

Pool Meadow |

Bradley and Robinson |

|

Clothiers |

John Hill and Company |

Portobello |

H. Ward |

|

Coppice |

J. Bagnall and

Sons |

Portobello

Bridge |

Fletcher,

Solly and Urwick |

|

Crescent |

J. Bagnall and

Sons |

New Portobello

Bridge |

Fletcher,

Solly and Urwick |

|

Crescent |

Addenbrook and

Company |

New

Priestfields |

William Ward

and Son |

|

Crescent |

W. Hartshorne and Company |

Robin Hood |

J. Simpkin |

|

Crescent |

Crescent Colliery Company |

Rose Hill |

Chillington

Iron Company |

|

Lane Head |

W. Mannix and

Bate |

Rose Hill |

Brown and

Spittle |

|

Lane Head Bridge |

Joseph Hawkins |

Sand Beds |

Fletcher,

Solly and Urwick |

|

Little London |

Trentham

Colliery Company |

Somerford |

Messrs Barker |

|

Little London |

Solly and Urwick |

Spring Bank |

Springbank Coal Company |

|

Little London |

Mark Gallear and Company |

Tame Mill |

Johnson and

Company |

|

Moat Field |

Dodd and

Southan |

Tame Mill |

Jos. Hincks |

|

Moseley Hole |

Chillington

Iron Co. and Others |

Trentham |

Isiah Hill and

Company |

|

Neachells |

S.

Croucutt & Sons |

Welsh End |

Isiah Hill and

Company |

|

Neachells |

John Sparrow |

Willenhall |

William Ward

and Sons |

|

Neachells Hall |

Barbersfield

Company |

Willenhall |

John Yardley |

|

Neachells |

H. B.

Whitehouse |

Willenhall |

Willenhall Colliery Company |

|

New Neachells |

P. Williams

and Company |

Willenhall |

Thomas Challoner |

|

New Cross |

H. B.

Whitehouse |

Willenhall |

George Hyde |

|

|

|

|

In the 1870s things started to go

wrong. A depression in the iron trade led to a fall in

the price of coal, which in turn led to the closure of

many mines. A long strike took place in the coalfield,

during which all labour was withdrawn. Pumping engines

were not operated, and many mines flooded. In 1870 it was

estimated that around 150 million tons of coal, and 20

million tons of iron ore were under water in South

Staffordshire.

Godson's map of Willenhall,

produced in 1800 shows a pumping engine near to the

junction of Bilston Road and Moseley Road. It is

described as a Crocket and Stokes engine, which would

have been steam driven, and used to pump water from

nearby mines.

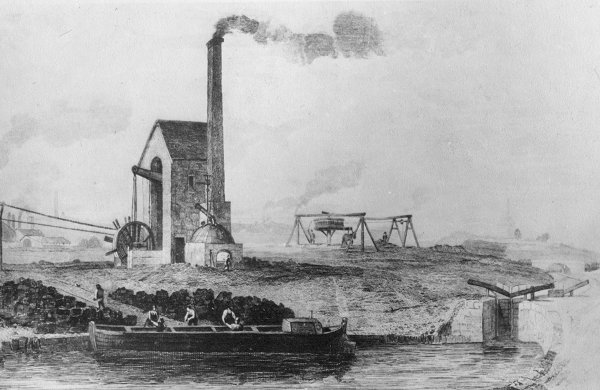

A typical gin pit. Courtesy of

David Evans.

Some mine owners would not use a

pumping engine because they were also draining their

neighbour’s pit at their own expense. Pumping also

altered surface drainage, because the water was run into

streams, which percolated back into the mines.

A petition to Parliament led to the

South Staffordshire Drainage Act of 1873. Under the

terms of the act, a Board of Commissioners was created

to raise money to fund pumping operations. A rate of one

penny per ton of coal, slack, and fire clay was levied

on the mine owners, but initially little progress was

made. In 1878 greater powers were granted to the

commissioners. During the next 10 years £100,000 was

spent on pumping water out of the deeper mines. In 1886

the levy was raised to nine pence per ton of coal, slack

and iron ore, three pence per ton of fire clay, with an

addition of one penny per ton for surface drainage.

Water courses were straightened, and made watertight by puddling the beds with clay. In spite of all the efforts,

the drainage problem was never solved, and the

Commission was largely ineffective.

A steam-powered winding engine,

and a gin pit. Courtesy of David Evans.

In 1896 W. Beattie Scott, H.M.

Inspector for the South Staffordshire mining district

compiled a report which listed all of the coal mines in

operation at the time. The mines in Willenhall were as

follows: |

|

Owner |

Colliery |

Underground

Workers |

Surface Workers |

Type of coal |

| A. Lowbridge, Short Heath |

Lanehead Bridge |

5 |

3 |

manufacturing |

| B. Piggott, Bilston Rd, Willenhall |

Mabbs Bank |

15 |

5 |

manufacturing |

| W. Bickley, Short Heath |

Pool Hayes |

104 |

26 |

manufacturing and steam |

| Samuel Habley, Short Heath |

Short Heath (part) |

3 |

2 |

|

| Head & Co. Short Heath |

Short Heath (part) |

6 |

3 |

|

| Joseph Tipper, Spring Bank |

Spring Bank |

2 |

1 |

manufacturing |

| S. Lester, Stringes Lane |

Stringes Lane |

11 |

4 |

manufacturing |

| G. H. Callear, Willenhall |

Trentham |

7 |

2 |

|

| The following list of Willenhall mines, compiled in

1908, is from Ancestry.com. It only includes four

working mines: |

|

Colliery |

Owner |

| Sandbeds (not working) |

T. Nicholls, Fairfield House, Willenhall |

| Bull Pleck |

Southan Brothers, Willenhall Road, Moseley Village |

| Junction |

Southan Brothers, Willenhall Road, Moseley Village |

| Neachells (closed in 1907) |

Southan Brothers, Willenhall Road, Moseley Village |

| Osier Bed |

Samuel Spruce and E. Powell, 10 Victoria Place,

George Street, Ettingshall |

| Rose Hill |

Samuel Weaver, 7 Walsall Road, Willenhall |

| Within a few years it was all over. The Willenhall

mining industry had lasted around 100 years, during

which time large numbers of people had moved into the

area to work in the mines. By 1910 the industry had

become less important. Large amounts of coal were

transported daily on the Wyrley & Essington Canal from

coalfields around Cannock, and also on the Bentley

Canal from coalfields near the BCN. |

|

|

|

|

|

Return to

The Workhouse |

|

Return to

the contents |

|

Proceed to

Local Government |

|