|

The Company's Products

This section contains details of some of the many and varied

products that were produced by the company from the early 1900s to the 1940's. At

this time the principal products were rotating electrical machinery, switch

and control gear, static transformers, and rectifiers. |

|

|

|

|

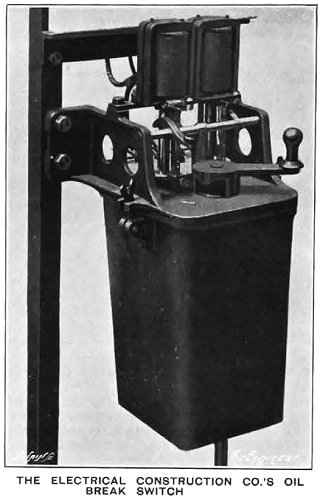

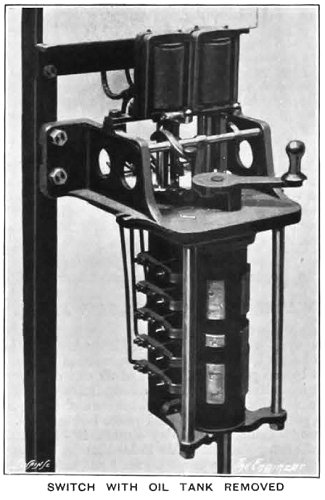

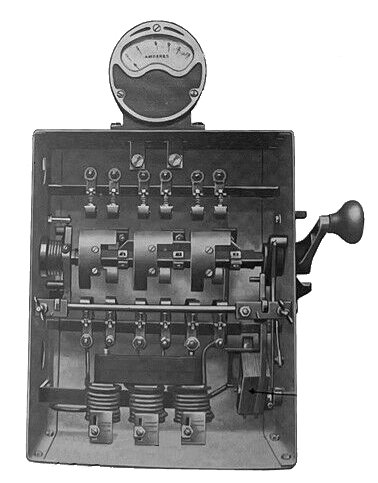

Two motor starting switches from 'The

Engineer' 25th August, 1911. |

|

|

|

|

|

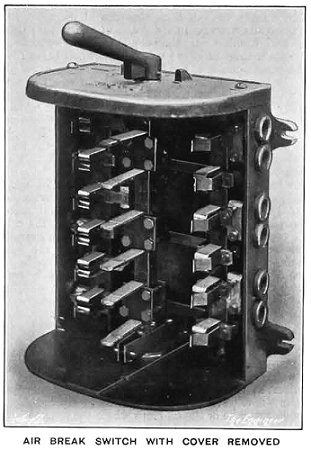

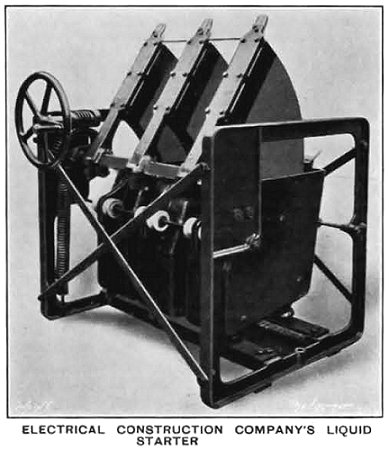

An air break switch and a liquid

resistance switch from 'The Engineer' 1st September, 1911. |

|

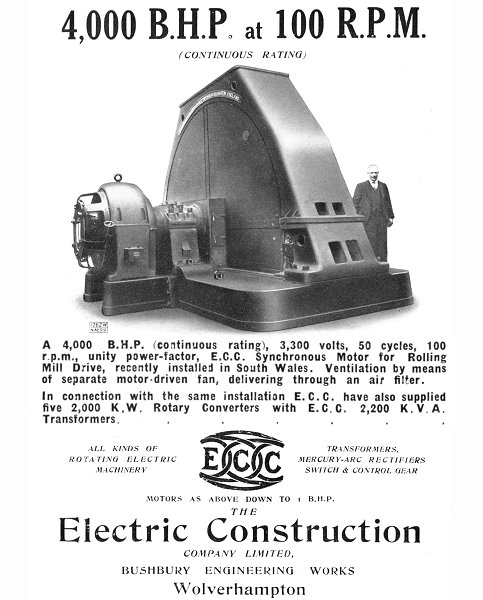

| An advert from 1920 showing an E.C.C. motor driving

a steel rolling mill. |

|

|

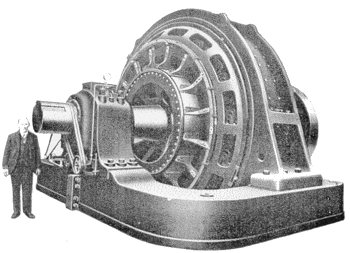

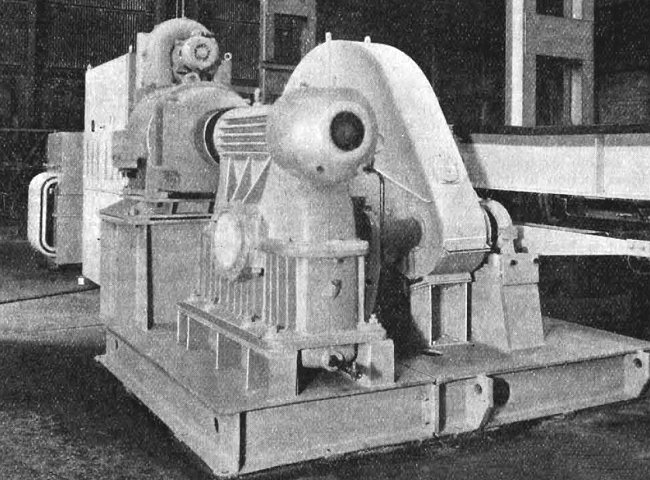

One of E.C.C.'s larger DC motors. It was installed at a

rolling mill and operated in conjunction with a steam-turbine driven

generator.

The motor was rated at 5,000 bhp., at 55 r.p.m. It was

reversible and could reverse direction from full speed in one direction,

to full speed in the opposite direction, in seven seconds. The speed

could be adjusted by varying the current in the field windings. The

maximum speed was 110 r.p.m. |

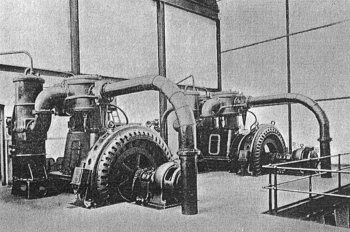

| Two synchronous three phase 600 bhp. motors, that were

used to drive air compressors in a colliery.

The motors also provided

power factor control, so that the equipment operated at its greatest

efficiency. |

|

|

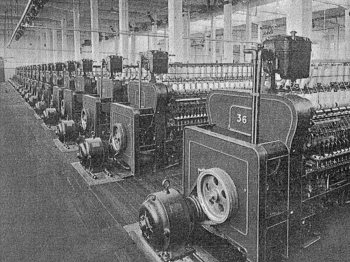

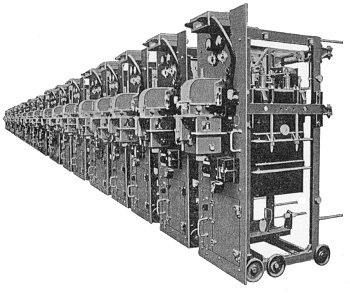

Part of a large installation at a spinning mill.

The

squirrel cage motors were capable of delivering 10 bhp., and were

driving ring-spinning frames. |

| The company produced switchgear to control all types of

AC and DC motors and generators.

Some of the switchgear, called "trucks"

was mounted on wheels to allow easy access.

The photograph shows part of

60 high tension "trucks" that were installed in a metropolitan borough

power station, to control the outgoing supplies. |

|

|

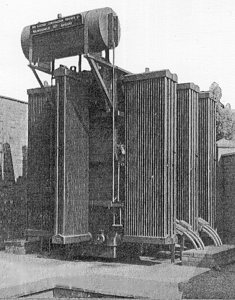

The E.C.C. built all types of transformers, up to

10,000 KVA. The photograph shows a 10,000 KVA unit of the outdoor

type, with a conservator and oil-cooling radiators. |

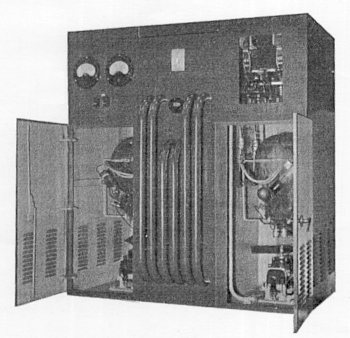

| A 2,200 volts, 65 kW rectifier unit, using two mercury

arc rectifiers, oil-cooled transformer and D.C. switchgear.

It was built

for a Corporation electricity department and delivered an output of

220 volts D.C. at 65 kW. |

|

|

A small metal-plate rectifier unit that was built for a

Government department and used to supply a wireless telegraph

communications system. |

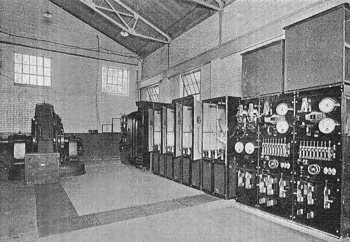

| The equipment opposite was installed in a steel works.

It consisted of a 500 bhp. motor, with a speed range of 150 to

350 r.p.m., a 750 kW rectifier unit, which provided 480 volts D.C., from

a three phase A.C. input, of 5,500 volts. There was also a second motor

that was rated at 350 bhp. The control switchgear is on the right. |

|

|

An E.C.C. patent varispeed drive, applied to a machine

tool. It consisted of a mercury arc rectifier, variable speed D.C.

motor, and the necessary control gear. |

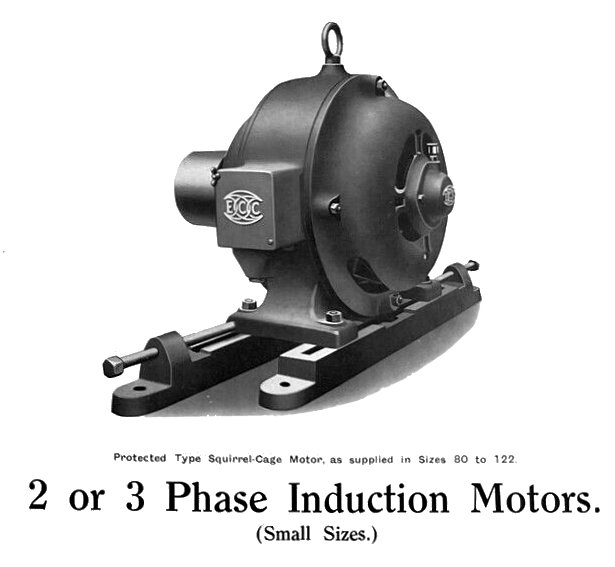

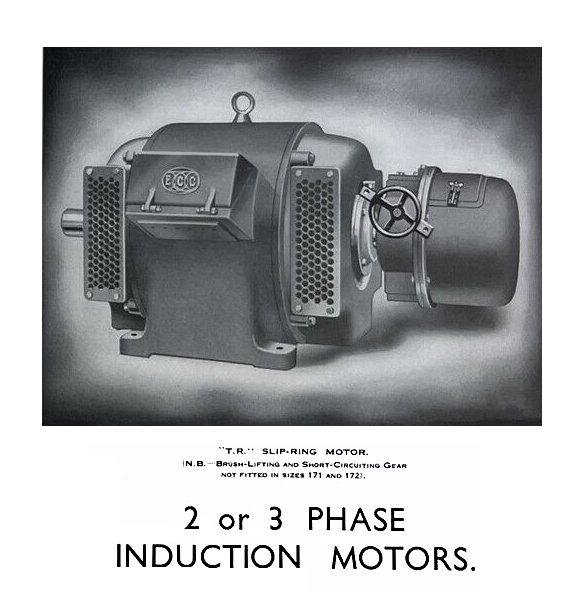

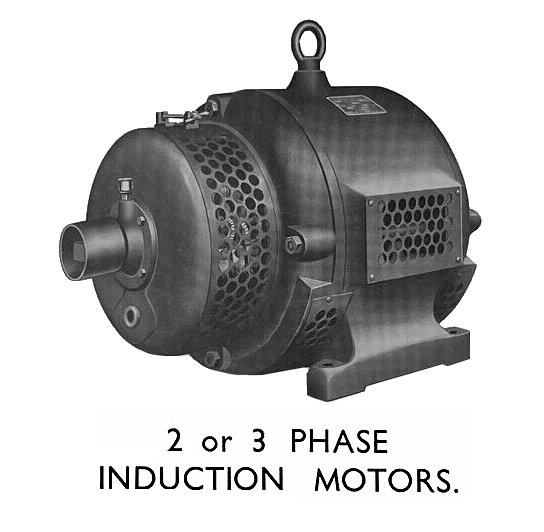

Early 1930s.

Early 1930s.

Early 1930s.

Motor starting switch from the early 1930s.

An advert from 1936.

| The following article about the E.C.C. 'Varispeed' system

appeared in 'The Engineer' on 8th November, 1946: |

|

A

Variable-Speed Power Drive

The problem of providing

variable-speed power drives is of considerable interest,

not only because it affects an ever-increasing number of

manufacturing processes, but because the solution

involves a choice between many methods, both mechanical

and electrical.

Amongst the more common electrical

methods of obtaining a variable-speed drive are change

pole induction motors, Ward-Leonard sets, AC. commutator

motors of various kinds, and, where a DC. supply is

available, the shunt-controlled DC. motor. Because of

its excellent speed characteristics, the shunt-wound DC.

motor commends itself to many engineers, but its use

nowadays tends to be restricted because of the modern

preference for individual drives in production machines,

coupled with the adoption of standard three-phase AC.

supply throughout this country. |

|

Particular interest therefore

attaches to the "Varispeed" drive developed and

manufactured by the Electric Construction Company,

Limited, Bushbury Engineering Works, Wolverhampton,

using a standard DC. motor supplied from AC. mains

through the medium of a mercury arc rectifier. The

rectifier supplies DC. separately to the armature and

field system of the motor, the two supplies being

independently variable. By this arrangement the speed

can be varied over a very wide range, as much as 1000 to

1, providing constant torque throughout this speed

range.

A simple single-phase circuit,

illustrating the principle of the system, is shown in

the accompanying diagram, in which the AC. supply is

connected to the primary of a transformer having two

secondary windings. The main secondary winding supplies

the two main anodes of a mercury arc rectifier, which

converts AC. to DC. for supplying the motor armature.

The auxiliary secondary winding is connected to two

auxiliary anodes to provide DC. for the motor field.

A maximum speed range of about 4 to 1 can be obtained

from a DC. motor of normal design by varying the shunt

field current while keeping the applied armature voltage

constant. Under these conditions the output horsepower

remains approximately constant throughout the speed

range, for the torque falls as the speed increases, that

is, as the field current is reduced. |

|

If, on the other hand, the shunt

field current is kept constant while the armature

voltage is varied, the speed of the motor varies

approximately as the applied armature voltage. By

varying the voltage supplied to the armature from zero

to maximum, an infinitely great speed range can be

obtained with constant maximum torque from the motor,

since the field current remains at its maximum at all

speeds. Maximum horsepower is therefore developed at

maximum speed.

Since the majority of drives

require maximum horsepower at maximum speed, with the

torque remaining constant at its maximum value

throughout the speed range, it is usual to use armature

control, which considerably reduces the overall size of

the motor. A further reduction in cost results from the

fact that armature control normally eliminates the

necessity for separate starting gear. The speed control

gear can be used to start the motor smoothly from rest.

A combination of armature voltage and shunt field

control can be applied with advantage in many instances

where maximum torque is required at some speed less than

full speed, or where some compromise between constant

torque and constant horsepower is required.

Assuming, however, that the field

is maintained constant, the motor speed will depend upon

the armature voltage supplied from the rectifier valve.

This voltage can be varied by anyone of several methods,

depending entirely upon the kind of drive and the speed

range required. Since the ratio of the DC. voltage to

the AC. voltage of the rectifier is fixed, a variable

DC. voltage can only be obtained by applying a variable

AC. voltage to the rectifier. In general, there are

three methods whereby the AC. and therefore the DC.

voltage can be controlled.

An E.C.C. 'Varispeed' drive for a draw bench.

The first method requires an

on-load tap-changing switch to vary the main secondary

voltage from the transformer in a predetermined number

of fixed steps. The second method employs an induction

regulator to vary the main secondary voltage smoothly

over a range designed to suit the speed range of the

motor.

The third method makes use of grid

control between the anodes and cathode of the rectifier,

giving smooth control over the DC. output voltage and

the speed of the motor. Normally the first method is

used for small machines, where a number of fixed speeds

is acceptable. With larger machines, when smooth speed

variation is important, either of the remaining two

methods can be used.

There are therefore three essential

components in the equipment; the transformer and

controller, the rectifier cubicle, and the motor itself.

All of these components can be mounted separately, which

allows considerable flexibility in layout. Wiring is

reduced to a minimum, since there are only three wires

between the rectifier cubicle and the motor (without any

intervening starter), and the fine wiring between the

rectifier cubicle and the controller.

A typical "Varispeed" installation

is depicted in the accompanying engraving, which shows a

267 hp. shunt-wound DC. motor driving an automatic draw

bench. The rectifier cubicle and the transformer can be

seen behind the main motor. This equipment, which is

entirely automatic, gives the motor a speed range of 0

to 1200 rpm. providing constant torque throughout this

range. An interesting point is the use of a forced

ventilating system which accounts, in part, for the

small size of the variable speed motor.

Since acceleration is completely

smooth throughout the speed range, the accelerating time

can be reduced to a minimum. The system lends itself

satisfactorily to automatic control, reversing duty,

dynamic braking, and rapidly variable acceleration.

Throughout the speed range the efficiency and power

factor of the system are high. It will be noted that the

rectifier has no excitation losses, since the excitation

is used to supply the field of the motor, resulting in

an appreciable gain in efficiency. |

|

|

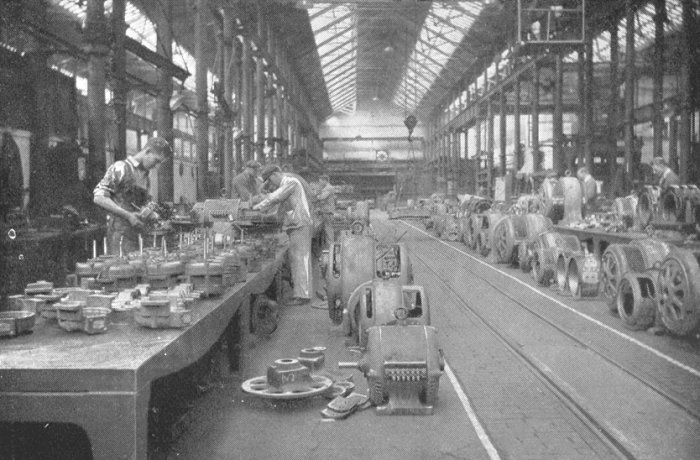

Assembling motors in 1938. |

|

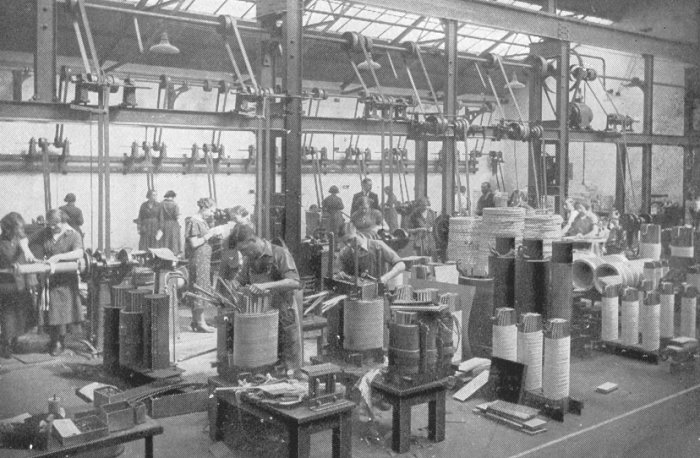

Assembling transformers in 1938. |

|

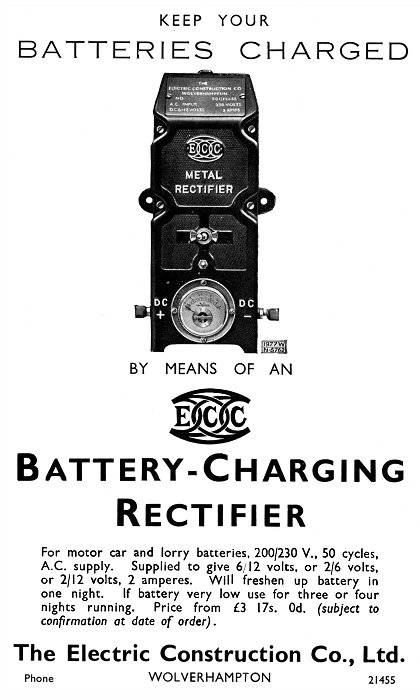

An advert from 1942. |

An E.C.C. battery charging rectifier. Courtesy of

Tamlin Roberts.

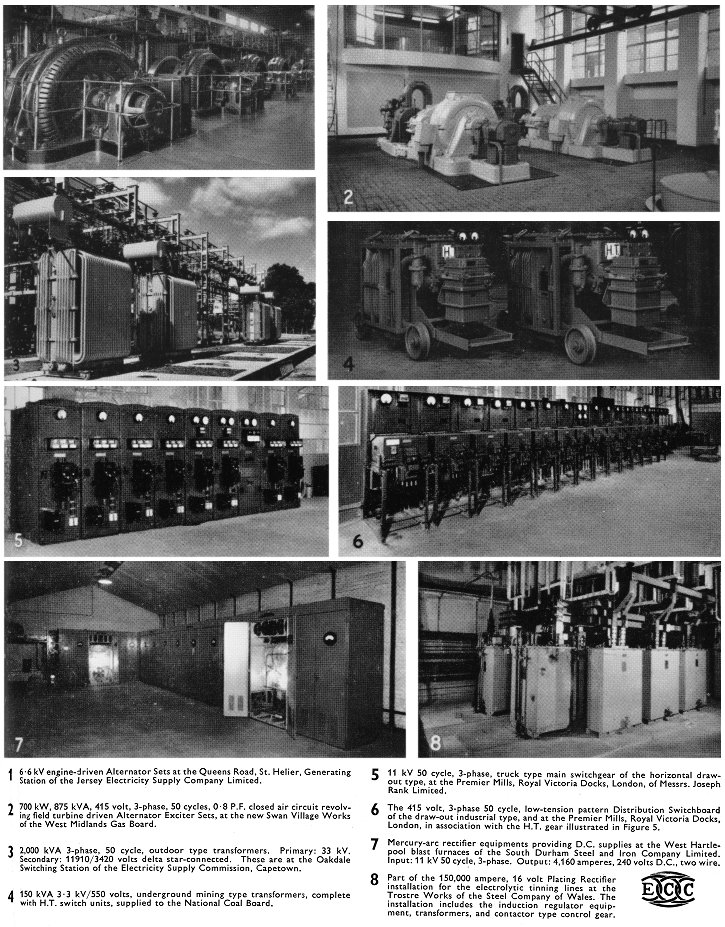

An advert from 1956.

|

|

|

|

|

| Return to

Bushbury Works |

|

|

|

Proceed to the

Later Products |

|