|

A history of Joseph Evans and Sons

Joseph Evans & Sons (Wolverhampton) Limited made all

kinds of pumps, from the smallest to the largest. Pumping was one

of the most important activities in industry. One of the earliest

applications of steam power was pumping water from mines, which allowed

mining companies to fully exploit their mineral deposits. Pumps are

essential for distributing mains water and gas, and for many industrial

processes. They are also used for agriculture, for the oil industry, and

for domestic purposes. They have almost endless applications.

Joseph Evans & Sons produced a wide range of pumps, of

all kinds, and all sizes, and became extremely successful, selling their

products throughout much of the world. The business was founded by Joseph Evans in 1810,

possibly in the Culwell area of Wolverhampton, after which the various

factories were named.

The first reference to the company I have found, is in

William White's 1851 History, Gazetteer and Directory of Staffordshire.

It is listed under Ironfounders as Joseph Evans, in Wednesfield Road. So

it must have been near the Cul Well.

|

| The firm is also listed in Harrison, Harrod & Company's Directory & Gazetteer of

Staffordshire, for 1861.

Again it is listed under Ironfounders, but this

time Culwell Foundry is on Cannock Road, so at some point the business

must have moved to new premises.

By 1862, Culwell Foundry had moved to Southampton

Street.

|

The location of Culwell Foundry in

Southampton Street. |

|

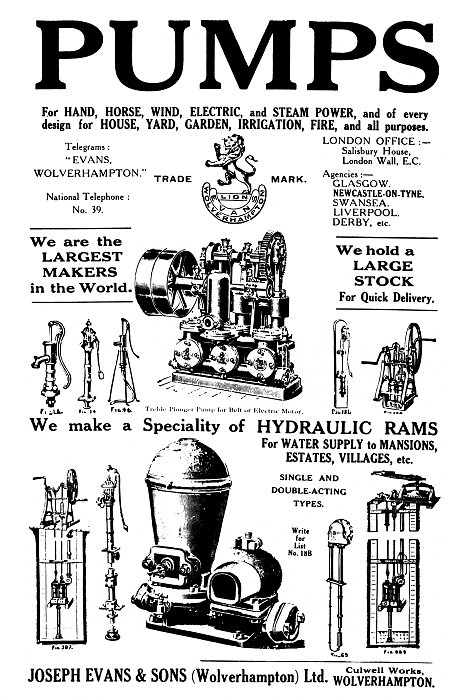

An advert from 1862. |

|

The location of Culwell Works in Woden

Road, Heath Town. |

The firm is listed in the 1892 Wolverhampton Red Book under Ironfounders, as Joseph Evans & Sons, Southampton Street.

Within five years the company had moved to its final

home, Culwell Works in Woden Road, Heath Town. The factory is shown on

the 1901 Ordnance Survey map, with all of the buildings present.

Woden

Road was a new development, it is not shown on the 1881 Ordnance Survey

map.

|

|

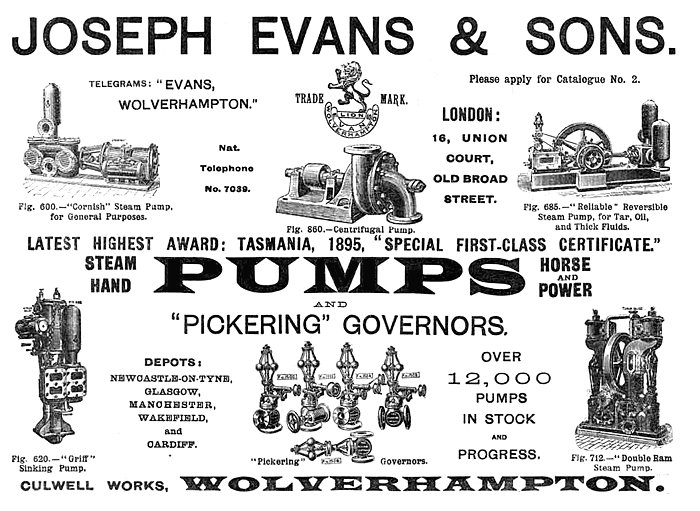

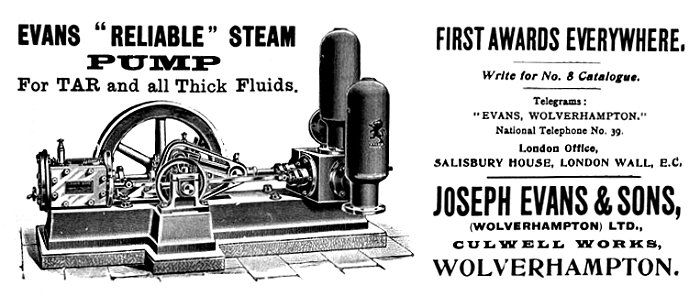

An advert from 1897. |

|

Clearly the company expanded rapidly, and possibly

quickly outgrew the earlier premises. Culwell Foundry in Southampton

Street is still shown on the 1901 map, but it is marked as disused.

The final factory in Woden Road may well have been built

there because of its close proximity to the London & North Western

Railway, and its Goods Station, from where a railway line ran into the

factory.

The company's early pumps were driven by horses or

bullocks, as can be seen in the first catalogues. One advert states that

the firm "can specially arrange our gears so that with bullocks walking

at the rate of 1½ miles per hour, the

crankshaft would make 30 revolutions per minute." Another states that

"calculations are based upon strong, powerful horses or ponies being

used. If inferior animals are substituted, the heights given will of

course not be obtained."

|

| The firm exhibited its products for the first time at

the Royal Agricultural Society's Show at Wolverhampton in 1871. The

display included horse-drawn pumps, and steam pumps. Their products were

again displayed at the Royal Agricultural Show at Birmingham in

1876, including the successful 'Reliable' steam pump, which was

available in a variety of forms.

The firm also had a stand at the 1881 Royal Agricultural Society's Show,

in Derby. Exhibitions became a valuable marketing tool.

Evans pumps were

also displayed abroad, at exhibitions, including ones in the USA, France, Australia, and

Austria. Gold medals were awarded for Evans' pumps at an exhibition in

Paris in 1867, and 1878, New York in 1872, Philadelphia in 1876, Vienna

in 1873, and Melbourne in 1889. |

The company's trade mark. |

The following is from 'The Engineer', 13th June, 1884:

Engineering at the Staffordshire

Exhibition

The machinery and industrial sections in the

Wolverhampton and Staffordshire Industrial and Art

Exhibition, which was opened on May 30th, and will

remain open until the end of October, are well-filled

with excellent specimens of engineering and similar

work.

As usual, several novelties are

shown by Messrs. Joseph Evans and Sons, engineers, of

the Culwell Foundry, Wolverhampton. As perhaps the

largest pump makers in the kingdom, they are, of course,

strong in this particular class of exhibit.

There is a double ram pump with 14

in. cylinder, 10 in. ram, and 11 in. stroke, and pumping

11,900 gallons per hour. The crank, crank pin, crank

shaft, and eccentrics, are all in one forging. The

"kite" is inverted, so that the momentum of the flywheel

is communicated to the ram direct. There is also a

portable Cornish steam pump and boiler; Tonkin's patent,

specially made for the water department of the

Birmingham Corporation for low lifts in emptying mains,

water pipes, etc. By the motion of a lever, one can

either exhaust into the chimney or into the suction

pipe, thus at once avoiding an escape of exhaust steam

in the chimney and producing a vacuum to assist the

pump. In the suction pipe is an enlarged chamber filled

with a grill to keep out stones. It can be immediately

cleared out by sliding open a door underneath.

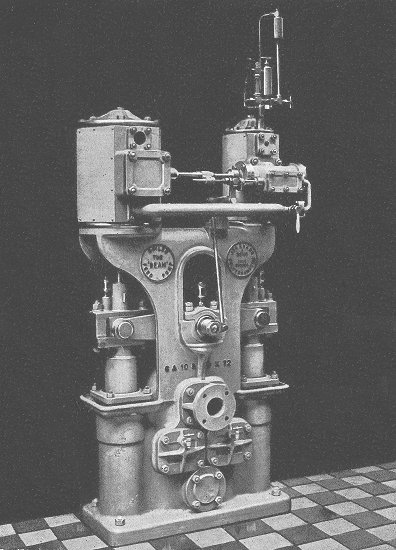

The Premier air pump and compressor

is convertible by a quarter turn of a lever on the same

principle as that in the Birmingham specialty. The firm

shows also an improved hydraulic press pump, and yet

working up to 5,000 lb. the square inch. The cylinder is

6in., with 6in. stroke, and ⅝ in. ram. Phosphor bronze

is used for the pump barrel and

valve chambers. |

|

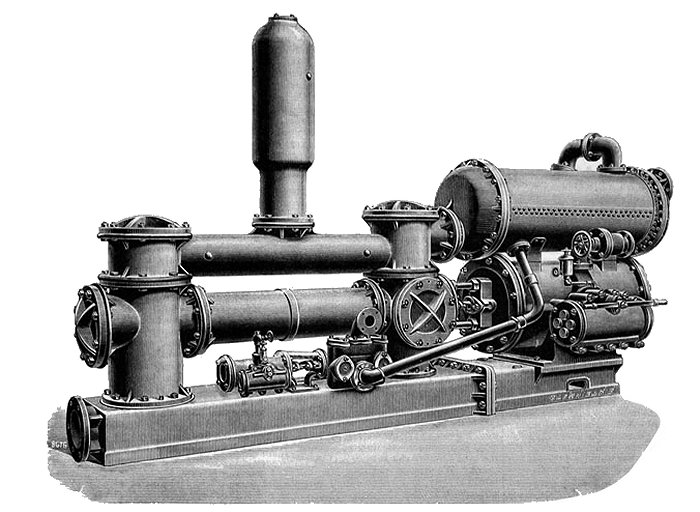

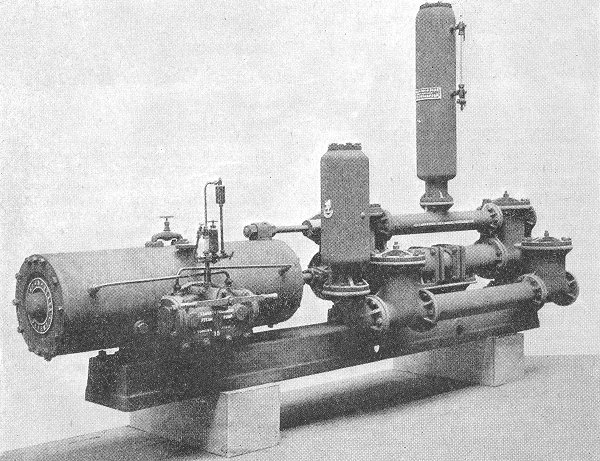

A direct-acting 'Cornish' pumping engine from

1888.

An advert from 1904 which shows some of the firm's

hand-operated pumps.

|

An advert from 1906.

|

In 1878 the firm became a Public Company, and by 1888

was producing a wide range of products. The catalogue for that year

includes hydraulic rams, steam engines, stamps, pumps, pumping machinery

and fittings. The machines were sold throughout the world.

An article in

'The Engineer' magazine in October 1892 describes a Compound Condensing

Duplex Pumping Engine for the water supply of Managua, Nicaragua, and

another article from August 1897 describes a pumping engine that was

supplied to the Miike coal mines in Japan.

In

1902 the company exhibited at the 1902 Wolverhampton Exhibition with a

Cornish steam pump and a vertical compound beam feed pump.

Evans

also supplied a battery of boiler feed pumps for use on the exhibition site. In

1907 Joseph Evans & Sons was Incorporated as a Private Limited Company,

and by 1914, there were several hundred employees.

By 1906 the company claimed, in its adverts, to be the

largest maker of pumps in the world.

|

|

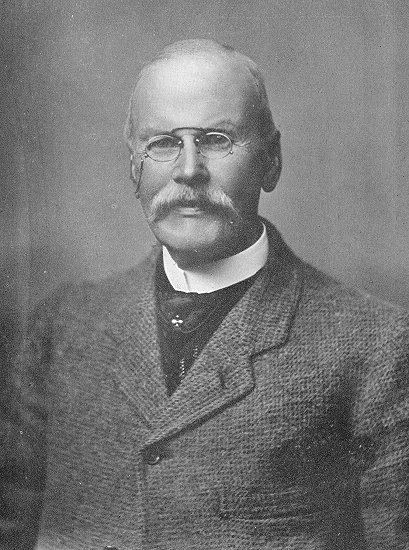

Joseph Evans died in February, 1908. Here

is an obituary from an unknown newspaper:

The death has taken place, at his

residence, the Lindens, Wolverhampton, of Mr. Joseph Evans, the

principal partner in the well-known firm of Messrs. Joseph Evans

and Sons (Limited), engineers, of the Culwell Foundry, Heath

Town. The deceased was the son of the late Mr. Joseph Evans, who

established the Culwell Foundry, in Wolverhampton. The business,

however, expanded to such an extent that new works had to be

erected at Heath Town. On the death of his father Mr. Evans

became a partner with his brother, Mr. William Evans (who

survives him), and since then the three sons of the deceased

have joined, the firm. Mr. Evans had been in failing health for

about two years, but he was able to attend to business up to a

fortnight ago. Mr. Evans was a staunch Churchman, a

Conservative, and firm believer in the Tariff Reform movement.

He was a. county magistrate, and sat at Wolverhampton. He was

sixty four years of age. A short time ago he gave three pieces

of sculpture to the Wolverhampton Art Gallery. "Psyche Borne by

Zephyrs," "Meditation," and "The Dancing Girl." |

Joseph Evans, J.P. |

An advert from 1909.

|

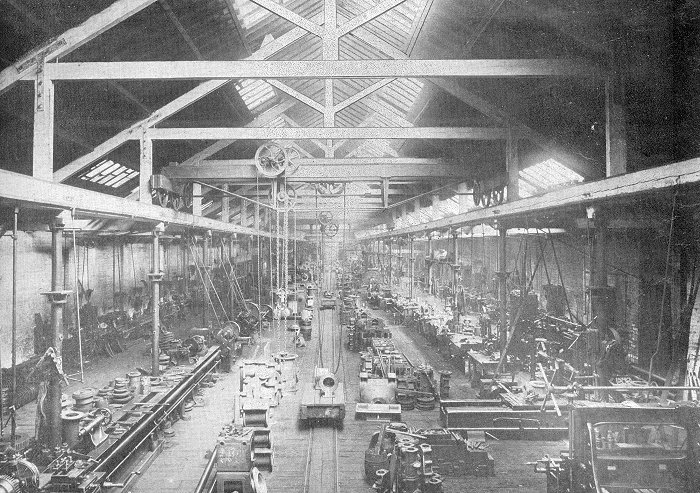

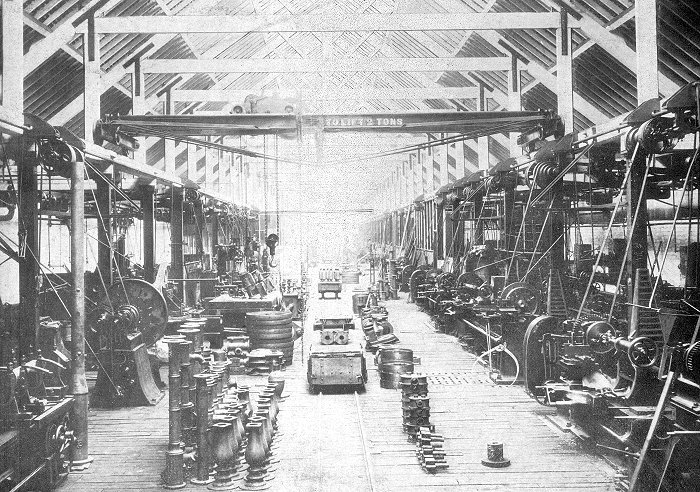

The Fitting and Machine Shop. |

|

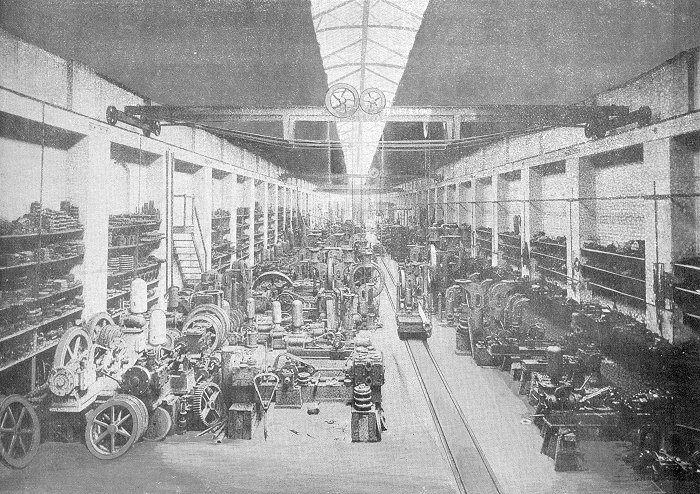

The steam pump department. |

|

The Hand and Power Pump Department. |

|

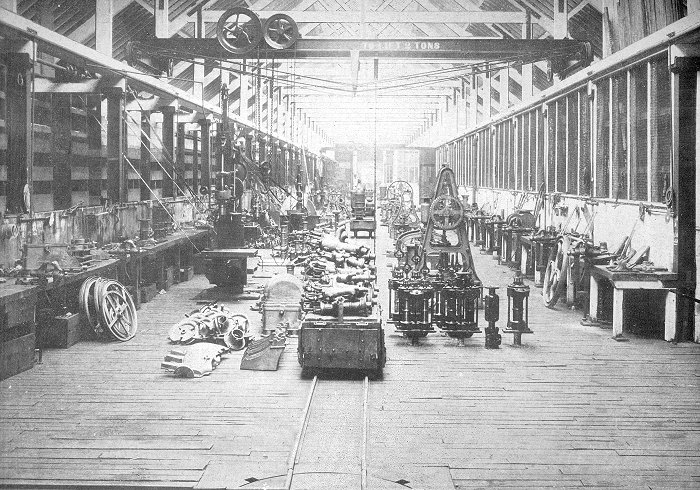

Another view of the Fitting and

Machine Shop. |

|

From 'The Engineer', 7th February, 1908. |

During the First World War the company supplied a range

of pumps to the War Department, including pumps for emptying flooded

trenches in France.

After the war, Lloyd George arranged for one of the

Evans family to be knighted.

The Baronetcy was given to Walter Harry

Evans, rather than to his older brother Osmond, who was not married and

so had no children. The second baronet is Sir Anthony Evans.

|

The company's letterhead.

An advert from Engineering Journal, 1909.

A 'Cornish' steam pump from 1902.

|

Other products were also produced at the foundry

including "Pickering" governors for steam engines, and all of the

cylinder castings for A.J.S. motorcycles. Jack Stephens, a member of the

family who founded and ran A.J.S. had served his apprenticeship at

Culwell Works.

During the second world war, Evans produced

the large pumps that pumped the oil through PLUTO (Pipe Line Under The

Ocean) which supplied the invasion forces after the Normandy

landings.

In

1944 Joseph Evans & Sons was taken over by Newman Industries of Bristol.

They were Electrical and Mechanical Engineers who specialised in

electric motors and built tractors.

Seven years later, Joseph Evans &

Sons was was sold to another pump manufacturer, the Pulsometer Engineering Company of Nine Elms Iron Works, Reading and

London.

|

A vertical compound 'Beam' feed pump from

1902. |

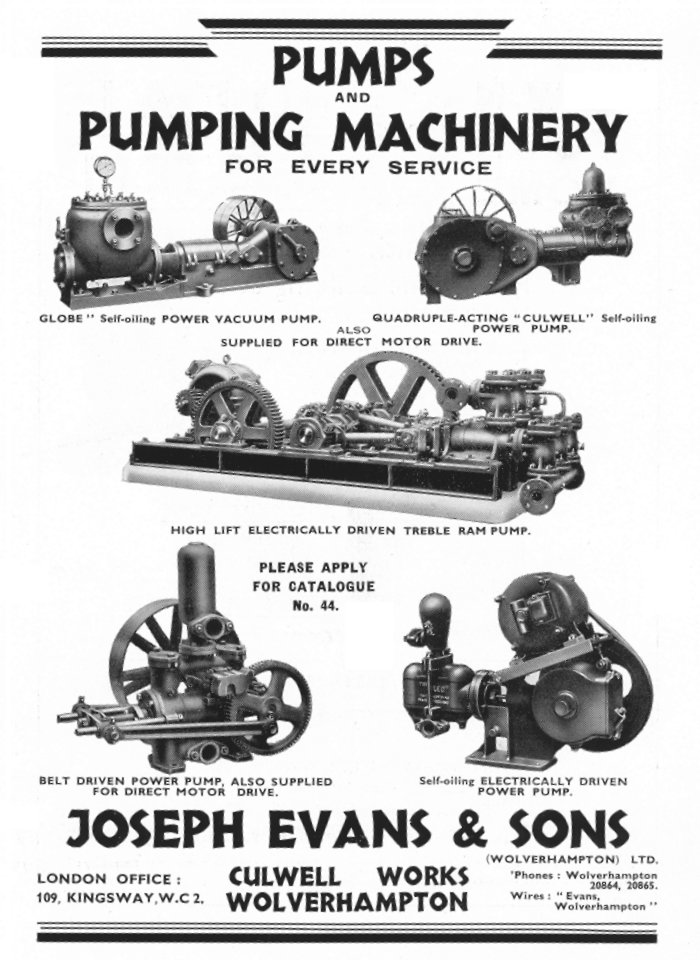

Another advert from Engineering Journal, 1909.

An advert from 1914.

An advert from 1912. The vast size of

the undertaking can be seen from the large number of pumps

in stock and in progress. |

An advert from the early 1930s.

|

An advert from 1953. |

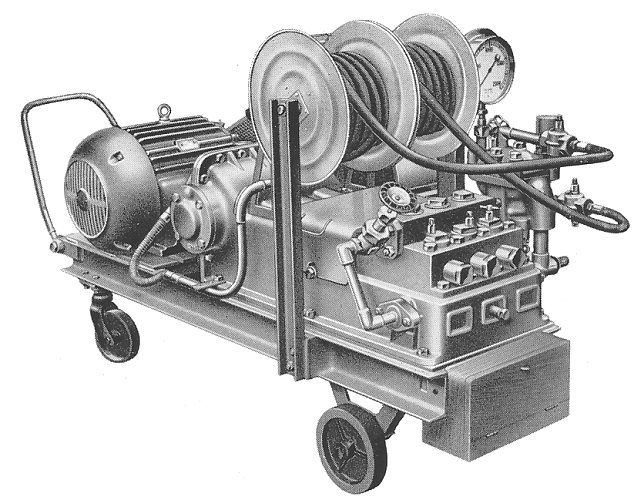

During the 1950s, Joseph Evans & Sons developed and

manufactured hydraulic high pressure cleaning units, using aerated water

at high pressure for difficult cleaning operations. The company also

developed a highly efficient piece of equipment for the water infusion

of coal, which forced water under high pressure into coal at the working

face, in collieries.

Experiments had shown that when water was infused into the coal,

the dust arising during the coal extraction process was considerably

reduced.

Also the infused coal tended to break-up more easily into sizes

suitable for handling by the mechanised plant, which was frequently in

use.

The Evans Water Infusion Pumps also reduced the amount of

shot firing that was required at the coal face. |

|

In conjunction with the parent company, Joseph Evans had

also been active in the design and manufacture of a new standard range

of centrifugal pumps, described as the 'Unistream Pumps'.

They had many

interchangeable parts and were suitable for mass production to lower the

cost, and make spares readily available.

The pumps could be supplied

with special parts for dealing with corrosive liquids.

In

1956 Pulsometer was acquired by Camp Bird Limited, a general mining

company and holding company, of Dover Street, London, and in 1957

Pulsometer was sold to the merchant bank, Philip Hill, Higginson and

Company.

By the 1960s the products included oil refinery

process pumps, pumps for mining, and pumps for municipal water supplies,

and drainage and sewage.

|

An advert from 1956. |

The Evans high pressure cleaning unit.

An advert from 1958.

| It seems that Culwell Works closed in the mid 1960s. It is listed in the 1964 Kelly's Directory, but not in the 1965 edition,

although it is still listed in the 1965 Wolverhampton Official Handbook. It

is a sad end to such a once-prominent, and long surviving manufacturer. |

|

|

|

| Culwell Works is now

part of an industrial estate.

Some of the old buildings, which date from Evans' time, still exist,

as is shown in the photos above. |

|

|

|

|

Return to

the beginning |

|

Proceed to

articles

from The Engineer |

|