|

Articles from 'The Engineer'

magazine |

|

The Engineer, 21st July, 1871.

The Royal

Agricultural Society's Show at Wolverhampton

Messrs. Joseph Evans and Sons, of Wolverhampton,

who exhibited for the first time, have made a very good beginning, and

give promise of taking a very prominent position as pump manufacturers.

Their 6 horsepower high pressure pumping engine has the pump and steam

cylinder on the same bed plate. We will only remark that it is effective

in design, and well and strongly made.

A bucket and plunger pump, No. 5592, to be driven

by horse power, has one end of the connecting rod working the plunger,

secured to the circumference of a disc; this not only simplifies the

construction of the machine, but as it does away with all gearing,

renders the machinery less liable to breakage in case the horse should

prove restive. They also display a great many lift and force pumps of

various descriptions, amongst which I may particularise No. 6617. This

is a 4 inch rotary lift and force pump. A block on the crankshaft moves

a long wrought iron link, up and down. The link is fixed at one side to

an upright arm, attached to the pump barrel, and is left free at the

other end, and to it is fastened the pump rod, the consequence of this

arrangement being, that the return stroke, in which no labour is

expended, is made very quickly. |

|

|

The Engineer. 25th August, 1871.

Steam Pumping Engine, Messrs. J. Evans & Sons,

Culwell Foundry, Wolverhampton

|

In the accompanying engraving we illustrate a

neatly arranged pumping engine exhibited by Messrs. J. Evans and Sons at

Wolverhampton, during the show.

The engine is six nominal horsepower,

non-condensing, and is fitted with an 8 inch diameter cylinder, 16 inch

stroke. The crankshaft carries a pinion 7 inches in diameter, working into a 28 inch spur wheel on the

pump crank. The pump is double acting, bucket and plunger, 8 inches

diameter, and the plunger is 5.625 inches diameter, with 10 inch stroke.

The valve on the bucket end of the

plunger is of India-rubber, and in the

form of a belt, which covers the ingress

holes. In the forward stroke, the valve

closes on the holes in the plunger, and

in the backward stroke expands with the

pressure of the water, passing through

the holes to the front end of pump,

thence to the delivery pipe. |

|

|

The suction and delivery valves are of the ordinary flap kind, and the

bucket is metallic, with a gun metal ring. The cranks, etc. are of best

wrought scrap iron, and the piston rod and connecting pin of steel.

It is designed for supplying estates, mansions,

public institutions, etc. and may be arranged for various heights for

lifting and forcing water. By disconnecting the piston, the machinery

may be used for any purpose to which an ordinary steam engine is

applied. The workmanship is very good, and the same may be said of the

design.

|

|

|

The Engineer. 28th July, 1876.

The Royal Agricultural Society's Show at

Birmingham

In my notice of steam pumps last week, I omitted to

refer to one which is novel, in the sense that it has not been exhibited

before. This is the 'Reliable' steam pump, exhibited by Messrs. Joseph

Evans & Sons of Wolverhampton. The most noteworthy feature about this

pump is the fact that in lieu of ordinary clacks the pump is fitted with

a slide valve. This valve is worked by an eccentric on the crankshaft,

which shaft is driven by a dog link intervening between the steam and

pump cylinders. The pump worked very well, and appears to be adapted for

pumping thick fluids.

|

|

|

The Engineer. 22nd July, 1881.

Exhibits at the Royal Agricultural Society's Show,

Derby

Messrs. J. Evans and Sons, of Wolverhampton, showed

Tonkin's patent pump at work. This pump is another of the multitudinous

class of steam pumps with steam moved valves, first invented about

twenty years since. It is very silent and quiet in its action. They also

exhibited some good rotary donkey pumps, coarse and strong, and well

fitted for rough work.

|

|

|

The Engineer. 16th

December, 1881.

The

Cornish Steam Pump

Messrs. Joseph Evans & Sons, Wolverhampton, Engineers

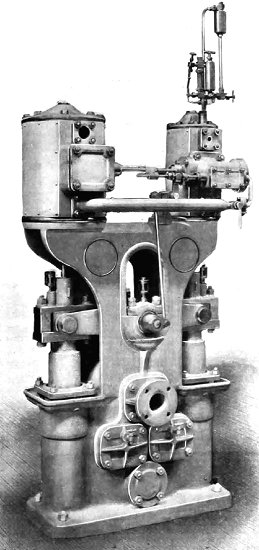

The engraving illustrates a new

type of steam pump, manufactured by Messrs. Joseph Evans

and Sons, of Wolverhampton, and Queen Victoria Street,

London.

Its Motion will be readily

understood from the drawing. As the piston approaches

the end of its stroke, say from right to left, the steam

from the cylinder is admitted by the ports K and M to

the left of the small plunger G, moving it to the right,

by which means the right end of the large plunger D is

placed in communication with the exhaust through the

ports N, and the left end with the interior of the steam

chest B, from which steam is admitted through the ports

R and Q, causing the plunger D, together with the common

slide valve F., to be carried over to the opposite end

of the steam chest, thereby reversing the motion of the

main piston; a similar motion takes place at the

opposite end.

The cushioning of the plunger

valves is most effectively performed by means of small

ports, through which steam direct from the steam chest

flows upon the end of the plunger towards the completion

of its stroke, and this prevents it striking up the

covers and caps; the exhaust steam from the plunger G

passes through the small port S, and thence into the

main exhaust through N. The steam chest being placed on

the side of the cylinder, and the bottom of the steam

port on the same level as the bottom of the cylinder,

the whole of the condensed water is carried out at every

stroke of the piston, whereby the necessity for drain

cocks is avoided. This appears to be a simple and

efficient pump, well adapted for doing a great deal of

work under trying conditions. There are few parts to get

out of order, and the whole machine will obviously stand

knocking about without injury. |

|

|

The Engineer. 20th May, 1892.

Letters to the Editor

Condenser Valves

Sir, In reading your very interesting article on

condensers in the current issue of your paper, we notice a mention of

some firms using valves with serrated edges. In fairness to ourselves, will you kindly mention

that the serrated valves are our patent, and explain that the object of

such serrations is to cause the valve rubber to partly rotate on the grating at each discharge,

thus distributing the wear equally over the whole face. We send you a

sample rubber, and you will notice that the serrations are diagonal, not parallel with the axis. This

simple device prolongs the life of the rubber quite twice as long. The

turning action also has the effect of sweeping off the face any foreign substance.

Wolverhampton, May 18th. Joseph Evans and Sons.

|

|

|

The Engineer. 7th October, 1892.

Compound Condensing

Duplex Pumping Engines For The Water Supply of Managua, Nicaragua

Messrs. Joseph Evans & Sons, Wolverhampton. Engineers

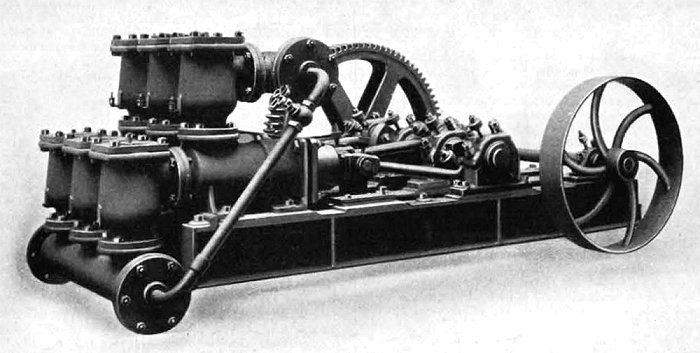

The pumping engine illustrated above has been

designed on the duplex principle, with Messrs. Joseph Evans and Sons'

improvements. There are two 12 inch diameter high pressure, two 20 inch

diameter low pressure steam cylinders, and two 12 inch diameter water

cylinders, all 12 inch stroke. The lever motion for working the valve

gear is fitted with telescopic pieces, having long bearing surfaces,

which are readily oiled from a lubricator provided at the top of each.

This arrangement dispenses with the usual radius links and pin joints,

thus reducing the number of wearing parts. The steam cylinders

throughout are lagged with sheet steel, packed with slag wool, and secured by brass bands, making a very neat and

efficient covering. Cushioning valves are fitted to each cylinder, also

a sight feed lubricator, and additional lubricators for the low pressure

cylinders and stuffing sleeves. The water cylinders are fitted with

easily removable barrels, secured in place by set screws, and are

provided with deep buckets and cup leathers.

The water valves are of Evans' patent rotating disc

type, with brass gratings and guards. The water from the delivery branch

is passed through the tubes of a surface condenser. For convenience of

space this latter is placed at right angles with the centre line of the

main engine. The barrel of the condenser is of wrought iron, double

riveted in the longitudinal seam, and doors of the full diameter of the

condenser are provided at either end for access to the tubes.

The exhausts from the low pressure cylinders are brought together by

means of a forked piece, and led through a two way valve, the latter

being provided for the purpose of turning the exhaust either to the

atmosphere or to the condenser, as desired.

The air pumps are on Messrs. Evans' Cornish

principle, with Tonkin's patent steam cylinders, each steam cylinder

being 5 inches in diameter, and each air pump barrel 8 inches diameter, all 12 inch stroke. The

air pump barrels are fitted with gun metal liners. The valves are on

Messrs. Evans' patent rotating system. All valves are above the water

cylinder, and the capacity is so adjusted that the water level does not

fall below the top of the pistons, consequently a very efficient air

pump is the result. Either one of the air pumps could on emergency do

the work. The engines are capable of delivering over 50,000 gallons of

water per hour. They have to draw their water from a lake l,000ft.

distant, through a 12 inch diameter suction pipe, and deliver through

6,000ft. of 12 inch delivery pipe to the reservoir 180 feet above the

pumps. The working steam pressure is 90 lb. per square inch. The engines

were made for the Nicaragua Company, Leadenhall Street, London, E.C.,

under the supervision of Mr. Heber Duckham, A.M.I.C.E., and are for the

extension of the water supply to the town of Managua. |

|

|

The Enginer. 1st

September, 1893.

Compound Duplex Pumping Engines

Messrs. Joseph Evans & Sons, Wolverhampton. Engineers

We illustrate above a pair of fine

compound duplex pumping engines constructed by Messrs.

Joseph Evans and Son, of Wolverhampton. The engines are

tandem, and fitted with a condenser, not shown, on a

lower level. The dotted lines show the exhaust pipe. As

regards the main valve motion, we may mention that the

high pressure cylinders are worked on the ordinary

Tonkin's patent steam moved valve system, and the main

internal steam plunger in the high pressure steam chest

is fitted with a slide spindle, which drives the low

pressure slide valve through an arrangement of

compensating levers. The object of this lever motion is

two-fold. In the first place, the low-pressure slide

valve face stands out considerably farther from the

centre line of the engine than the high pressure face,

and the lever is a convenient method of bringing in the

centres to suit. In the second place, the width of the

ports and the travel of the valve is greater in the low

pressure cylinders than in the high pressure, and it

will be noticed that the horizontal vibrating lever is

pivoted at the end nearest the centre of the engine, but

the thrust is taken at an intermediate point between the

pivot and the outer end; in other words, it is a lever

of the second order.

It will be observed from the

engraving that the steam chests are low down on the

cylinders, and the bottom of the steam port is below the

bottom of the cylinder in each case, the special object

of this arrangement being to drain the cylinder through

the exhaust without the necessity of drain cocks, and

the arrangement which Messrs. Evans adopt entirely in

their direct acting steam cylinders is found to answer

admirably.

The crossover pipes on the high

pressure steam cylinders are for the purpose of

operating the slide valves so as to drive the duplex

motion which is affected as follows:

Both sides of the engine travel together, but the left

hand side is half the length of the stroke in advance of

the right hand side, consequently one side of the engine

only reverses itself at a time, the other side at the

instant of it neighbour's reversal is in the centre of

its travel and going at full velocity, hence the water

column is kept in motion and there is no appreciable

alteration in the flow of delivery. Should it happen

from any cause that one side of the engine became

disabled, the cross over pipes can be shut off by means

of the cocks provided and shown outside the high

pressure steam cylinders when the valve motion of each

cylinder would be worked on its own account as an

ordinary double action pump, the disabled half being

meanwhile shut off both as regards the steam and water

connections, suitable valves being provided for the

purpose, and any repairs needed could be effected at

once, while the remaining available half of the engine

cou1d continue to work.

In the pumping engine under notice

there are outside packed double-action rams, each 14

inches in diameter, with tail rods at the outer ends to

equalise the displacement, and also to carry part of the

weight of the rams. The water valves are of the patent

rotating rubber disc type, working on brass gratings and

the lift regulated by suitable saucer shaped guards. The

rubber discs which are of special quality, arrived at

after much experimenting, are serrated on the edges

diagonally; the water in upward flow impinges on the

diagonal serrations, and, on the reaction turbine

principle, causes the rubbers to partly rotate on each

beat, thereby equalising the wear all over the faces. It

is stated that cases are known where, after being in

wear for six or eight months, they have become reduced

in thickness more than 50 percent, and yet perfectly

even all over the face. A valve has been sent us by the

makers which fully substantiates this statement. The

centre boss of the valve guard fits in the centre hole

of the rubber and forms a bush, thereby preventing the

wear due to rotation coming on the rubber. A small

amount of lift is allowed in the centre of the valve so

that there may be free rotation.

Though not shown in the engraving,

there are independent air pump condensers in connection

with the engine. The condensers are placed on a lower

level than the main engine bed, to give a good fall for

the condensation water from the steam cylinders. The

condensers are of the injection type, with a large

condensing chamber. The air pump barrels are 10 inches

in diameter by a 24 inch stroke, gun metal lined. The

steam cylinders, which are on Tonkin's patent, direct

acting system, are each 8 inches in diameter by a 24

inch stroke, and are carried on strong distance pieces

overhung from the condenser ends. Convenient doors and

covers are provided throughout to pumps, cylinders,

condensers, etc. for ready access to the internal

portions.

A substantial girder bed plate is

provided under the steam cylinders and back pump boxes,

the forward pump boxes being carried on box feet

connected to the back portion by bridge pipes, which

latter also serve to tie the pump together. Large air

vessels are provided, and all details worked out to best

advantage, so as to be as convenient as possible for

underground use.

The pumps deliver about 1,400 gallons of water per

minute, 360 feet high, with 80 lb. per square inch steam

pressure. They are fitted in a large colliery in the

Newcastle upon Tyne district where a number of large

engines on the same principle, by Messrs. Evans, have

been in successful operation for sometime past. |

|

|

The Engineer. 10th

January, 1896.

Letters to the Editor

Drowned Pumps

It may be in the recollection of

your readers that a few weeks ago the Dungannon

collieries, Ireland, were suddenly inundated by an

enormous body of water tapped from some old workings,

and which unfortunately resulted in serious loss of

life, besides overwhelming the pumping machinery.

Mr. Donald Munro, the managing

engineer of the colliery, advises us that they have been

able to start the large Cornish duplex steam pumping

engine, supplied by us to the colliery, and that it is

working 60 feet under water. We think this will be of

interest to those who have to do with underground

pumping machinery, and shows in a remarkable manner the

capabilities of the direct-acting type of engine.

Joseph Evans & Sons, Wolverhampton.

January 8th. |

|

|

The Engineer. 16th

April, 1897.

Letters to the Editor

Sir, If the notice you give of a

pump regulator in your last week's issue is intended to

bring before your readers a novelty, we would like to

say that the same idea has been applied by us upwards of

ten years ago on a pumping engine for Leamington Spa,

and since then to engines for the Barry Dock, Vale of

Leven, and Vale of Glamorgan Waterworks, etc. We claim

to "go one better" also, as in addition to controlling

the supply, we have provided for the bursting of the

delivery main.

Joseph Evans & Sons, Wolverhampton.

7th April, 1897 |

|

|

The Engineer. 6th

August, 1897.

Evans

Pumping Engine

We illustrate a fine pumping engine

for underground working, lately constructed by Messrs.

Joseph Evans and Sons, of Wolverhampton, for use in the

Miike coal mines in Japan. The engine, as will be seen

by the illustration, is of the direct acting type, and

consists of two complete compound engines, arranged side

by side on bed plates, their steam distribution gear

being so arranged that under ordinary conditions the two

engines work together on the duplex principle, so as to

keep up a continuous flow of water; but when desired the

two sets of valve gear can be disconnected, and one of

the engines can be kept at work while the other is at

rest. The disconnection of the two sets of gear is

effected entirely by the manipulation of certain stop

valves, and is the work of a very short space of time.

The makers claim for this system

that it gives practically the advantages of two engines,

the working of the valve gear and the arrangements and

strengths of the various parts of the pumps being such

that if one engine is stopped for repairs or attention

of any sort, the other engine may with safety be run for

a time at a greatly increased speed, so that but little

pumping capacity is lost until such time as the second

engine can again be put into work. The principal

dimensions of the engine are as follows:

High pressure steam cylinders, 24

inches diameter; low pressure ditto, 44 inches diameter;

stroke, 36 inches. The duty for which the engine was

designed is to raise 2,000 gallons of water per minute a

height of 600 feet. The water to be dealt with is gritty

and impregnated with sulphur, and in consequence is of a

strongly corrosive nature, and with a view to resisting

this corrosive action, the rams, rods, and other working

portions of the pump are made of a specially resistant

bronze.

The engine is provided with a

surface condenser, having tubes and tube-plates of

brass, the water raised by the pumps being employed as

cooling water. The condenser is fitted with two

independent air pumps of the direct acting type. The

steam distribution valve gear of the engines and also of

the air pumps is of the well known steam-moved type

which Messrs. Evans have manufactured for many years

past, the gear of the main engines being Evans and

Tonkins' patent modified form of gear for enabling the

pumps to work in duplex or independent of each other, as

above described.

One steam relay drives both sets of

slide valves on high and low pressure cylinders. The

pump ends are provided with vacuum chambers on the

suction inlets, as well as air vessels placed on the

connecting pipes between the delivery valve boxes, and

all the valve boxes are arranged so that they can be

opened and the valves lifted quite clear of other parts

of the machine. The pumps are of the externally-packed

plunger type, and all parts of the pumps are arranged so

as to be easily accessible. |

|

|

The Engineer. 5th

July, 1901.

Wire

Rope Driven Treble Ram Pump

| In the accompanying engravings we

illustrate the latest design of triple

ram pump made by Joseph Evans and Sons

of Wolverhampton. It is intended for

high lift work in mines, etc. and is

arranged to be driven direct by wire

rope.

On the left is shown the whole pump;

Fig.1 is a section through the valve

boxes; and Fig. 2 a section of the rope

wheel.

As will be seen, this rope wheel is

not of the ordinary grooved type, but is

fitted with a tread, and the driving

rope goes round the rim one and a half

times.

The pump is rated to deliver 18,000

gallons of water per hour against a head

of 750 feet.

The general design will readily be

seen from the illustrations. |

|

|

|

| The gearing between the rope pulley

and the crank shaft is half shrouded.

The countershaft and crankshaft are

of mild steel; the latter, which is

provided with circular webs, being cut

from the solid and carried in four

pedestals fitted with gun metal

bearings.

The connecting rods are of steel,

fitted at the large ends with gun metal

marine heads. The small ends are solid,

and are provided with adjustable gun

metal bearings.

The pump rams are of close-grained

cast iron, and are cottered to the

crossheads, which are fitted with

slipper blocks carried by adjustable

slide bars. |

|

The suction and delivery valve boxes of the pump are

interchangeable, as are also the pump barrels, without

an unnecessary number of joints, and the stuffing-boxes

and glands are bushed with gun metal. The pump valves,

which, as will be seen, are of the double beat type, are

also of gun metal, and an air vessel is also provided.

The whole plant is mounted on cast iron girders forming

the bed plate. We understand that this form of bed plate

has been found the most suitable for conveying to the

destination in mines.

| It will doubtless be inquired what

ratio of efficiency is to be obtained

with this system of driving, and on this

point the makers inform us that they

have found that where an installation of

pumps on this principle is operated near

the bottom of a shaft, and near the

driving engine, it works out much less

in cost than would a similar

installation driven electrically. The

reasons for this are that in the former,

the losses of the dynamo and motor are

omitted, and their first cost saved.

A smaller engine at the surface can

moreover be used, since a well arranged

wire rope transmission will give to the

crankshaft of the pump as much as 90

percent of the brake horsepower of the

engine.

Further than this, in the position

where this pump was to work, it was

calculated by the mine engineer that the

first cost of the wire rope transmission

would be as nearly as possible the same

as the electric cable switchboard,

appliances, etc. The net result,

therefore, was that a smaller engine

could be used, and the dynamo and motor

omitted, while the cost of the

transmission system was the same as

compared with an electrical

installation. |

|

|

In the particular instance of this

pump we are informed that a comparison of the two

systems showed an estimated saving of nearly 50 percent

in first cost, and an ultimate saving of 25 percent in

the subsequent working cost of the rope-driven

arrangement, as compared with an electrically-driven

plant on the same duty.

Of course, if the work of pumping

is required to be done at some considerable distance

from the source of power, the advantage becomes much

more in favour of electricity, because of the upkeep of

the rope, and the losses in it. As a fact, however, the

cost of upkeep of electric cables in mines is very high.

Joseph Evans and Sons inform us that they have supplied

a large number of these pumps for various duties, with

heads varying from 600 feet to 1,700 feet, for both

mines and waterworks. |

|

|

The Engineer. 4th July, 1902.

Boiler Feed Pumps

For the feeding of the main range of boilers at the

Wolverhampton Exhibition, Joseph Evans and Sons have installed a battery

of feed pumps. They are fixed in an extension of the boiler house and

draw their water from a storage tank which is supplied from the

Corporation mains.

Compound Horizontal Feed Pump, Wolverhampton Exhibition.

The boiler pressure is 180 lb. per square inch, and

the discharge water passes through a relief valve loaded to 200 lb. per

square inch pressure when not required in the boilers. There are in all

three feed pumps, all of which are compound, two of them being horizontal and fitted with the makers'

patented Cornish system of compound steam cylinders, and double-acting

outside packed ram pump ends. The steam cylinders are 9 inches. and 16

inches. in diameter respectively, the rams being 7½ inches in diameter,

and all having a stroke of 24 inches.

Each of these two pumps is said to be capable of

delivering 8,000 gallons of feed water per hour against full steam

pressure, and each to be capable of providing the maximum amount of

water which the boilers are likely to be called upon to evaporate. On

the other hand, it is stated that they can run at as low a rate as two

piston feet per minute. The valves in the pump end are of the double

beat type, and are made of gun metal with flat faces. Each pump has a

large air vessel and a vacuum chamber, with the object of reducing

shocks both on the suction and delivery sides to a minimum. Indeed, as

might be expected from pumps made by this firm, all the three are

working with no noticeable noise or vibration of any kind.

| The third pump is of a new type. It is a

vertical compound pump, having steam cylinders 6

inches and 10 inches diameter,

and two 6 inch diameter single-acting rams, all of 12 inch stroke. This

pump possesses some novel features in the valve motion and general

arrangement. It is stated to be capable of delivering about 3,500

gallons of water per hour to the boilers, and is intended to deal with

the ordinary day load.

The makers, who call this pump the Beam Pump,

inform us that this new type of pump has been specially designed for

such work as that of electricity supply stations where the load is very

variable, altering, perhaps, from the maximum to almost nothing in a

short space of time.

They state that some of the more recent types of

pump, notably the duplex type, have not proved entirely satisfactory for

this class of work, and that while the double-ram flywheel type of pump

is satisfactory to a certain extent, it has the disadvantage of not

being able when required to run at a sufficiently slow rate of speed.

Moreover, they urge that the length of stroke which can be given to the

flywheel type of pump is limited, since, in order to get any length of

stroke, the vertical height of the pump itself would be increased beyond

reasonable limits. |

Vertical Compound Beam Pump. |

In the beam feed pump, the crank motion of the

flywheel is dispensed with, but the same vertical arrangement of steam

cylinders and rams is retained, the two sides being connected together

by means of a steel beam vibrating on a central shaft. Each pump ram has

a crosshead and slide arrangement so as to allow for the radial motion

of the beam. The actual travel of the slipper block is small; for a ram

of 12in. stroke it is about l inch. The high pressure cylinder is placed

over one ram and the low pressure cylinder over the other.

The steam

valve motion is driven by means of a small crank on the end of the beam

shaft, connected up by means of a rod to a small ‘L’ shaped lever

mounted on a bracket. This lever, in its travel, moves over a small

auxiliary valve working in the high pressure steam chest, and so admits

steam to either end, as the case may be of a piston working in a small

auxiliary cylinder. This piston is coupled by a spindle to both the high

and low pressure slide valves, so that, when driven over by the steam,

it reverses the slide valves of both steam cylinders simultaneously. The

auxiliary valve already mentioned is also a small slide valve, and is so

arranged that it uncovers the ports at the extreme end of its travel

only. By its use we are informed that the speed of the pump can be

reduced down to a mere crawl. |

|

|

The Engineer. 6th October, 1922.

Electrically Driven Treble-Ram Pump

There has been recently a

considerable amount of discussion among mining engineers

as to the relative merits of electrically driven

reciprocating ram pumps as compared with electrically

driven turbine centrifugal pumps, and although the

latter have admitted advantages, chiefly in their first

cost and the smaller space occupied, many engineers and

mining men still hold the opinion that the treble-ram

pump is more efficient in power consumption, and is more

reliable in operation than the turbine centrifugal type,

especially in cases in which a moderate amount of water

has to be raised to a considerable height.

Horizontal, Treble-Ram, High-Head Pump.

We illustrate above a treble-ram

pump constructed by Joseph Evans and Sons (Wolverhampton

Limited, which was installed recently at a colliery in

Scotland where the work of pumping had formerly been

done by turbine centrifugal pumps. The pump has three 9

inch diameter rams, 12 inch stroke, is fitted with

single reduction, double helical, machine moulded

gearing, and on the countershaft there is a belt pulley,

5ft. 9in. in diameter.

Power is transmitted from a 24in.

diameter pulley on a Metropolitan-Vickers direct current

motor by means of a balata belt. The bed plate of the

pump is formed of four cast iron longitudinal girders,

braced together at the end furthest from the pump

barrels by a cross girder, whilst the pump barrels

themselves are provided with bracketed feet, which span

the girders, and are secured by fitted bolts, thus

thoroughly bracing the bed plate girders together at

that end. The slides on which the crossheads work also

span the girders in the same manner, and thus form

additional bracing. The side plates being separate from

the bed, can be adjusted vertically to compensate for

any wear that may take place.

The three working barrels are

interchangeable, while all the six valve boxes are also

separate and interchangeable with one another, so that

in case of mishap or breakage only a comparatively small

portion of the pump need be renewed. The crank shaft has

four bearings provided with heavy gun metal adjustable

steps, giving ample wearing surface, and the pedestals,

being separate from the bed plate are independently

adjustable so as to ensure proper alignment and

facilitate the compensation for any wear that may take

place. The connecting rods are of cast steel with

adjustable brasses at each end. The crossheads are

constructed separate from the rams, and have large

slipper area to take the thrust from the connecting

rods.

The valves are of the maker's high

duty type, having gun metal mitred plates, which are so

arranged as to take the main load when the valves close

on their seats, but water-tightness on the mitring is

not attempted; the slight annular space between the

valve plate and the seating is sealed by means of a

rubber disc on the back of this valve plate, and

superposed thereon is another plate which takes the

pressure of the spring. The valve plate works on a

renewable stalk, and it will be noticed that the sleeve

of this member of the valve is "blind-ended," so that

there can be no passage of water in case of wear. From

many careful measurements of the discharge water under

heavy work, it has been found by the makers that the

volumetric efficiency of pumps fitted with these valves

is frequently 98 or 99 percent.

In the case of pumps of this

construction dealing with water containing grit and

foreign material, these valves are found to have

considerable advantage. The mitre faces of the metallic

portion do not allow grit or similar material to remain

on the sloping faces, but if by any chance such material

should lodge there, the rubber sealing disc will close

over and make the valve water tight in most instances.

This type of valve has been used by Messrs. Evans in

pumps working against heads up to 1600ft. with quite

satisfactory results.

The pump described above was tested

under actual working conditions and without any attempt

specially to tune it up, and the following results have

been furnished by the makers:

Static delivery head against pump,

632.5ft.; friction due to about 750ft. run of 7in.

delivery pipe, 6ft.; vertical height of suction, 15ft.;

friction through 150ft. run of 7in. suction pipe, two

retaining valves and certain bends, 4.5ft. Total head

pumped against from all causes, 658ft.; speed of pump

crank shaft, 41 revolutions per minute; power

consumption, 128 amperes at 485 volts, giving at an

efficiency for the motor of 90 per cent., 74.88

horsepower at the motor pulley; weir measurement, 330.6

gallons per minute; calculated theoretical pump

displacement, 338.7 gallons per minute; volumetric

efficiency of pump, 97.6 percent; horsepower in water

raised against the total head from all causes, 65.9;

showing a mechanical efficiency for the pump of 88 per

cent.

At the same time, a test was

carried out on a nominal 300 gallon per minute turbine

centrifugal pump, working in the same house and under

precisely the same conditions. The turbine pump was

found to deliver 260 gallons per minute only, and the

current used was 230 amperes at 500 volts, giving a

mechanical efficiency therefore of only about 40

percent. The turbine pump has been in use some years,

but has had new impellers and other renewals from time

to time. The Evans treble-ram pump was ideally designed

for a head from 800ft. to 900ft., and would have shown

an even higher efficiency on this latter head or if

designed for the actual head at which it is now working.

The motor driving the Evans pump is also at a

disadvantage, seeing that it is of 150 horsepower,

whereas it is only called upon to give under 75

horsepower in actual running. |

|

|

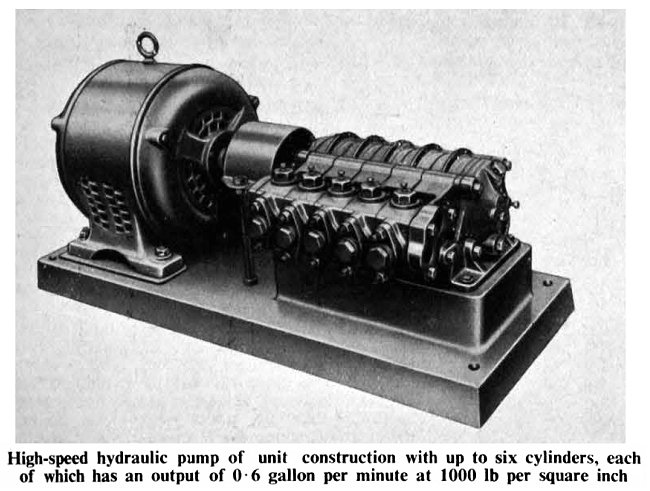

The Engineer. 18th

March, 1960.

Multi

Cylinder High Speed Hydraulic Pump

A design of high speed hydraulic

pump or unit construction and with from three to six

cylinders has been produced by Joseph Evans and Sons

(Wolverhampton) Limited, for applications where a

high-pressure pump of very small capacity is required. A

typical example of one of these pumps is shown in our

illustration. Each cylinder has an output of 0·6

imperial gallons per minute, and a six cylinder unit

would thus have an output of 3·6 imperial gallons per

minute. Delivery pressure is 1,000 lb per square inch.

The eccentric shaft of the pump, which is mounted on

roller bearings, is coupled directly through a flexible

coupling to the motor, which runs at a synchronous speed

of 1,000 rpm.

The pumps are suitable for

operation with water, water/soluble oil mixture, or

hydraulic oil as the working medium and the design can

be adapted for use with other liquids. The units can be

provided with spring-loaded relief valves, or

alternatively with automatic unloading valves, which

enables them to run light when operating against closed

stop valves. |

|

|

|

|

|

|

Return to

History |

|

Return to the Engineering Hall |

|

Proceed to the

1897 catalogue |

|