| The Turner Manufacturing Company

originated as an engineering business around the middle

of the 19th century. Amongst their early

products were velocipedes, bicycles, tricycles and cars.

The early business had various premises including works

in Brickkiln Street, Walsall Street and later Lever

Street. It was known as Thomas Turner & Company.

Around 1902 the company’s owner,

James Burns Dumbell, a very astute business man, decided

that the way forward lay in the production of motor

cars, and so the manufacturing rights of a well

established vehicle, the Belgian Miesse steam car were

obtained. It is believed that Turners, at least for a

time, purchased running chassis from the Brussels based

company of J. Miesse and simply added their own

bodywork. |

|

The Turner-Miesse steam car at the Black Country

Living Museum, Dudley. |

In 1906 the firm became a private

limited company under the name of the Turner Motor

Manufacturing Company Limited with Mr. Dumbell as

Managing Director. Around the same time they began to

manufacture their first petrol engined cars under the

name of Seymour-Turner.

|

Read about

Turner cars |

|

|

Car manufacture

continued until the beginning of the First World War

when Turner’s manufacturing came under the control of

the Ministry of Munitions who gave them a contract to

produce machine tools. As a result the company developed

one of the earliest motorised capstan machines, at a

time when most pieces of machinery were still

belt-driven from overhead line shafting. The machine was

extremely advanced and it continued in production until

the Second World War when the Ministry of Defence

directed Turners to sub-contract production to Jowett of

Idle, Bradford.

Other machines

were also developed including a self-contained motorised

tool-cutter, and a gauge grinding machine, both of

advanced design. Production again continued until the

Second World War, when the Ministry of Defence

transferred the work to the Turner Tanning Machine

Company of Leeds.

After the First World War, car

manufacture restarted with an unsuccessful and

short-lived joint venture with Varley Woods, but Turner

cars did not reappear until 1923. In the early 1930s

Turners produced a small booklet which included the

details of the company's early history and described its

various departments at Wulfruna Works, Lever Street. |

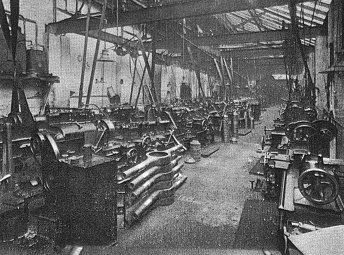

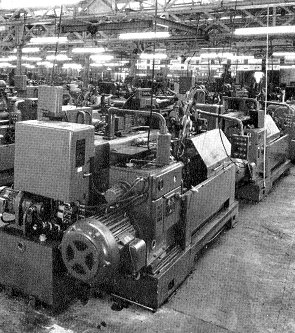

| The Capstan Department had an excellent range of

over 30 capstan and turret lathes from

⅛ inch to 4 inch capacity.

The machines included No. 4, No. 9, and No. 15 Herbert

capstans and several machines of the company's own

manufacture. |

The Capstan Bay. |

|

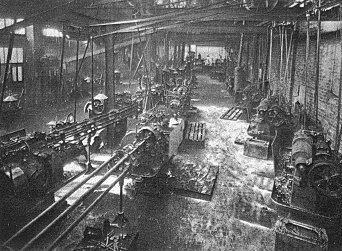

The Automatic Bay. |

The Automatic Department had a variety of 4 spindle

and single spindle machines that were used for quick

repetition work. Parts could be machined up to 1⅝

inch diameter. |

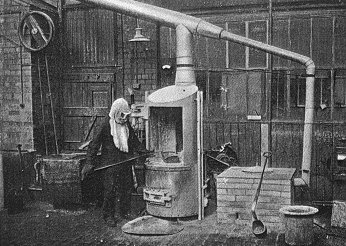

| The Hardening Department had an up-to-date system

using the Muffle furnace and the salt bath method. Salt

bath furnaces were installed in the machine lines to

facilitate rapid production. All furnaces were

scientifically controlled. |

A corner of the Hardening Shop. |

|

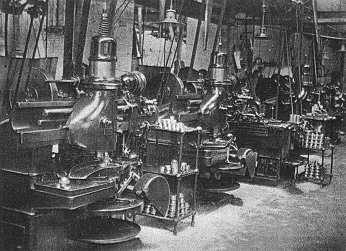

A few machines in the Gear

Cutting Department. |

The Gear Cutting Department had a variety of

machine tools including Fellowes gear shapers,

Barber Colman spline millers, broaching machines,

gear hobbing machines, and tooth rounders. Efficient

testing apparatus was also installed. |

| The General Machine Shop had many special machines

and a large variety of machine tools. There were lathes,

milling machines, planing machines, boring machines, and

drilling machines. Grinding could be accommodated up to

14 inch diameter by 96 inches long. The Inspection

Department carried out careful inspection of all the

material that entered the works, using the most

up-to-date equipment. All machined parts were inspected

both during and after manufacture.

The Drawing Office facilities were available to

customers for the development of their requirements. In

the Fitting Shops complete production of a component was

preferred wherever possible. Ample space for the purpose

was available in the Assembly Shop.

The booklet ends with the company's motto: "The

accurate product at the right price".

During the inter-war years Turners

foresaw the slump that took place in the machine tool

industry and turned their attention to components for

heavy road vehicles. Many valuable contracts were

obtained for rear axles, steering boxes, and gearboxes.

Other products included air springing for cars, outboard

motors, printing machinery, baking machinery, universal

joints, and patented tie rods.

By 1926, Wolverhampton heavy

vehicle manufacturer Guy Motors had developed a rigid

six-wheeled military truck with drive on both rear

axles. |

| This proved to be an excellent

cross-country vehicle for use as an artillery tractor,

mobile workshop, or searchlight generator lorry. Turners

were invited to develop a powered winch for the vehicle,

to haul it out of difficult terrain or recover field

guns etc. The winch was a great success and became

standard equipment for the Guy military trucks, which

were produced in large numbers.

In fact Turners became the leading UK

vehicle winch manufacturer, producing models for all of

the leading vehicle manufacturers and were responsible

for the complete range of powered winches used by the

British Army. |

A Guy six-wheeler in operation. |

| In 1928 Turners ceased to produce

cars and extended their product range to include

components for the aircraft industry. They began to do

research work for the Ministry of Defence, and in 1934

the Managing Director at the time, Mr. P.B. Dumbell

acquired a licence to manufacture Oleo pneumatic

aircraft landing gear. In 1937 the company's engineers

began to produce their own designs for pneumatic and

hydraulic undercarriages, and at the onset of World War

2 Turners became one of the three companies approved to

design aircraft undercarriages. As a result their

undercarriages were used on Spitfires, Avro Ansen

Trainers, and Stirling, Blenheim, and Lancaster bombers.

Tail wheel units were also produced for the Blenheim,

and Lancaster bombers. |

|

Moorfield Road Works. |

By the mid 1930s the company had

outgrown the Lever Street works and in 1936 part of the

old Sunbeam works at Moorfield Road were acquired for

expansion.

The works has since been

substantially modernised and a two-storey car park was

built on top of the machine shops. |

| Large numbers of aircraft

undercarriages were produced between 1939 and 1945, but

as ever the company kept ahead of the game. Turners

realised that after the war there would be little demand

for such products and so diesel engines were developed

for automotive and marine applications. |

|

In the late

1940s Turners began to manufacture an agricultural

tractor, called ‘The Yeoman of England’, built around

one of their four cylinder diesel engines. The company

also formed Light Delivery Vehicles Limited who operated

from the Lever Street works and produced light delivery

vehicles such as the By-Van and the Tri-Van.

|

|

Read about the light delivery vehicles and

the tractor |

|

A 'Yeoman of England' agricultural

tractor. |

|

The new factory at Fordhouses. |

In 1951 the company acquired a

factory on the Stafford Road at Fordhouses, which was

expanded and developed to undertake heat-treatment,

grinding and assembly work.

|

| In 1961 the neighbouring premises

owned by Spring Washers Limited was acquired and the

buildings were updated and turned into one of the most

modern heat treatment centres in the country. The entire

site now covered 15 acres.

The diesel engines continued to sell well and in 1954 at

the time of the Korean War, the company received a

contract from the Air Ministry to produce parts for the

Rolls Royce Dart engine, and parts for Westland

helicopters, including rotor heads, tail rotors, and

undercarriages. Although the orders for Rolls Royce

engine parts soon came to an end, Turners continued to

supply Westland for many years. |

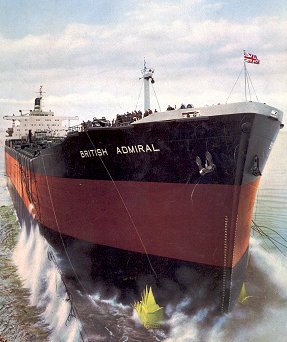

| In 1957 the company branched out

into the hydraulics and pneumatics field with the

formation of Hydraulics & Pneumatics Limited.

The new company manufactured all kinds of hydraulic

equipment including cargo control and handling equipment

for many of the world’s super tankers.

|

Read about Hydraulics

& Pneumatics Limited |

|

One of the super tankers fitted

with Hydraulics

& Pneumatics equipment. |

| Turner’s management began to

think about the large-scale production of gearboxes and

so in 1960 the company acquired gearbox manufacturing

rights from the Clark Equipment Company of America. The

Clark design was initially used in all Turner gearboxes

until the company had designed and developed its own

range. |

|

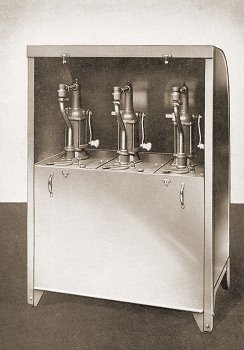

A Baelz triple 25 gallon cabinet. |

Expansion

continued in 1966 when Turners took over Baelz Equipment

of Wolverhampton. The company manufactured oil storage

and dispensing equipment, and lubricating equipment.

|

|

Read about Baelz Equipment |

|

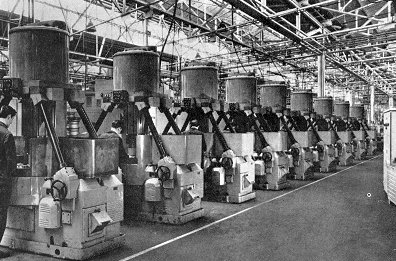

| A view of Turner's machine

shop showing a battery of vertical automatics in

operation. |

|

|

Another view of the machine

shop showing some

of the copy lathes. |

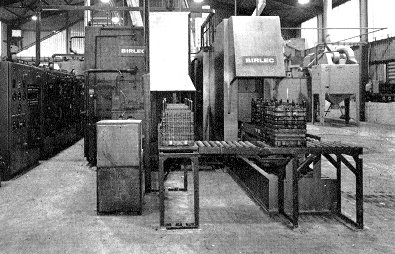

| A view of part of the heat

treatment plant. |

|

|

In June 1968 the

Turner Manufacturing Company Limited became a public

company. At the time there were 1,700 employees. The

directors were:

|

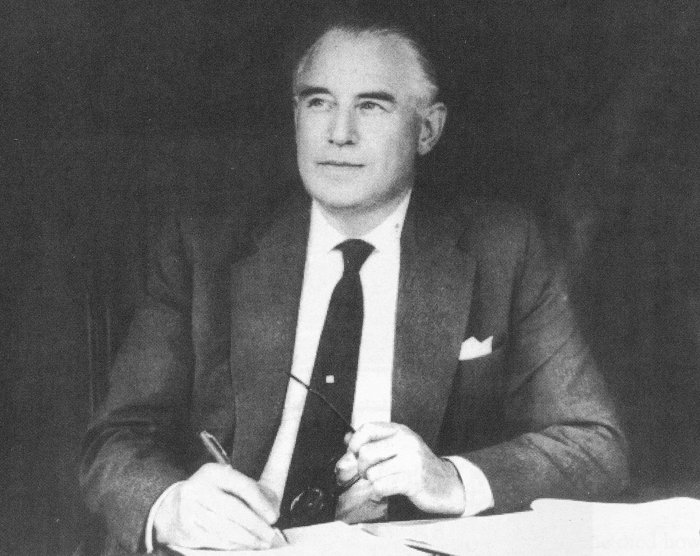

P. B. Dumbell |

|

Chairman. |

|

R. B. Dumbell |

|

Managing Director. |

|

C. F. Dumbell |

|

Financial Director. |

|

B. F. Brown. |

|

Commercial Director. |

|

W. E. Gibbs |

|

Production Director. |

|

W. M. M. Morrison |

|

Technical Director. |

|

M. C. Stoddart. |

|

|

Mr. Philip Dumbell, Company

Chairman.

Philip Dumbell married Marjorie

Sharpe, and they lived at The Gables in Tettenhall.

Marjorie died in 1970, and two years later Philip

married his secretary, Elizabeth Turton. Sadly the

marriage was short-lived. Philip died in 1977.

During the

company’s first year as a public company, sales amounted

to £6,829,000 and the profit after tax was £784,743.

Around 1967 Turners purchased Earby Light Engineers

Limited, a sub-contractor who produced precision

components for the aircraft engine and airframe

industries, and specialised in high precision work

including spark erosion and electro-chemical machining.

The company continued to expand and a new factory was

purchased at Racecourse Road in 1970.

|

|

View some of Turner's Products |

In 1972 the Dana

Corporation of Toledo, America acquired a 35% holding in

Turners and later took the company over. Turners

suffered greatly during the recession of the 1980s with

many job losses, and the loss of the subsidiary

companies. The Moorfield Road works closed in 1988,

leaving only one surviving factory, at Racecourse Road.

I would like to thank Derek Beddows

for his help in producing this section. |

|

Return to

the

Engineering Hall |

|