| Views of Guy Works. By David Townsend |

An aerial view of the factory with Park

Lane in the foreground.

These photographs are from a collection I was given by the Guy

works photographer, at the time Guy's finally closed. They would

have been taken for publicity purposes or record purposes, and seem to date from the late 1940s or early 1950s.

The tour of the works starts with the aerial photo above, which

shows the following:

|

Top left |

Low Hill estate |

|

Centre left |

Guy's sports ground: the upper

section is the football ground, with tennis courts

to the left; the lower section is the cricket

ground; between them is the bowling green the sports

pavilion and the new works canteen |

|

Centre right |

The area behind the factory is 'the

field' used as a parking area for any vehicles

awaiting attention in the works |

|

Middle left |

The works of ABC Coupler, which after closure,

was acquired by Jaguar and became the Guy service department |

|

Middle centre |

Guy's works. The white topped

building to the left was built when Sunbeams were

incorporated into Guys, and known as the Sunbeam

Machine Shop. It contained the machinery bought over

from Sunbeam. The high, white-topped building across

the top of the works was built as a double decker

bus body shop and known as 'The Hangar'. The buildings

facing Park Lane contained all the offices,

including the drawing office |

|

Middle right |

Part of Henry Meadows works, with

the Park Lane entrance running alongside the Guy

works. The houses between Meadows' works and Park

Lane may have been owned by Meadows |

|

Bottom left |

The bus depot |

|

Bottom right |

Every Ready |

|

|

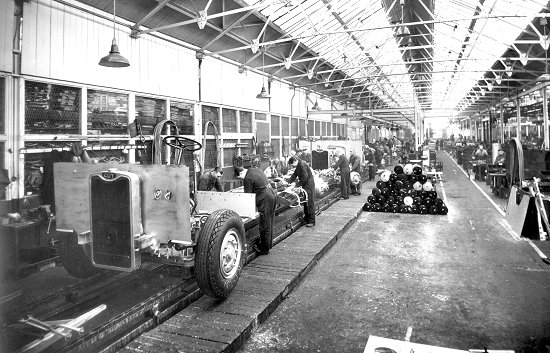

The Heavy Track. At this time it would only have taken buses,

as no heavy lorries were being made. Later it would have

taken 'Invincibles', 'Warriors' and, eventually, 'Big Js' and Leylands. Guy was the first heavy vehicle manufacturer in the country to

install a 'track', which was a kind of conveyor belt moving the

vehicles along the production line.

|

|

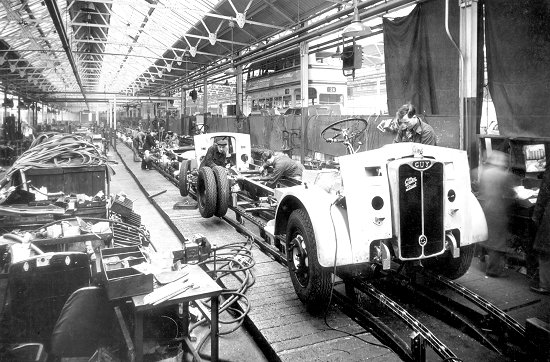

The end of the Light

Track, which took 'Otters', 'Vixens' and

'Wolfs'. Here is an 'Otter' diesel at the

last stage, which included fitting

tyres, controls and radiators. In the background is one of the 100

'Arab' buses supplied to Birmingham

Corporation, probably back in the works

for adjustments after running in. |

|

The Service Department section which undertook the overhaul and

repair of components. |

|

Across the bottom of the

photo is the start of the Light Track,

on which lighter vehicles were

assembled. To the right is a 'Vixen'

chassis about to go on to the track,

where the first thing to be fitted is

the engine. On the centre left the Heavy Track

started, and there is a bus chassis about

to go on to it. The whole area at the

back of the photo is the Assembly Area. |

|

The Drawing Office. This room was originally the canteen. The

Drawing Office moved there when a new canteen was built on the

Sports Ground. |

|

The Parts Store with the main roadway leading into the Machine

Shop. On the floor are Gardner HLW engines, and in the racks are GLWs. The stocks may seem large but at that time engines were

hard to come by, and you bought as many as you could, when you

could. |

|

The Spare Parts Stores. Guy always seemed to carry a very

large stock of spares. |

|

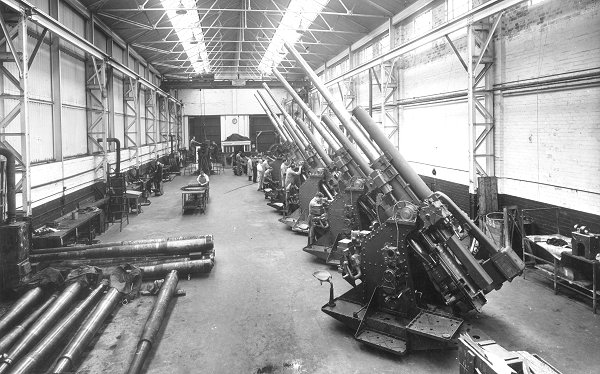

Anti-aircraft guns in

'The Hangar', the part of the works

originally built for building bodywork

for double decker buses. The guns were being refurbished and

adapted for radar guidance under a

contract with the Ministry of Defence. This sort of contract probably followed

on from war time work for the Ministry

on such items as armoured cars. |

|

The Service Department section which undertook engine

reconditioning. The engines are Guy and Meadows petrol

engines. |

|

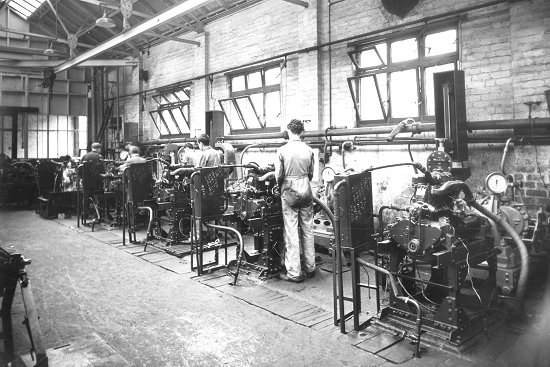

The Engine Test House. These are petrol engines being run in,

tested and tuned. |

|

Gear cutting machines, middle floor. |

|

Top floor. On the right are large plain cylindrical grinding

machines doing a chucking job. In the bottom right hand corner

is a balancing stand for the grinding machines. Cincinnati

machines on the left. |

|

The Machine Shop, top floor. On the left, note the overhead

drive shaft, but there is only one belt in place. By this time

belt drives were rapidly going out of use in most factories. |

|

The Machine Shop. In the background are Herbert continuous feed

machines. |

|

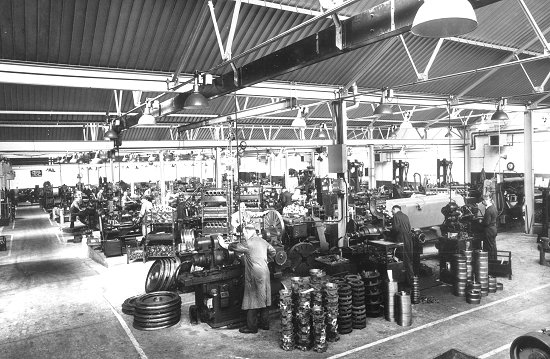

The Sunbeam Machine Shop which contained all the machines which

were brought over from Blakenhall when the Sunbeam works were

closed. |

|

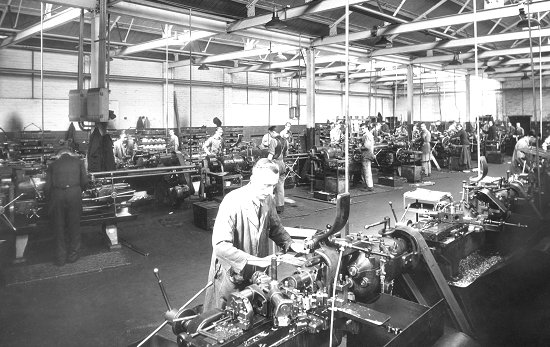

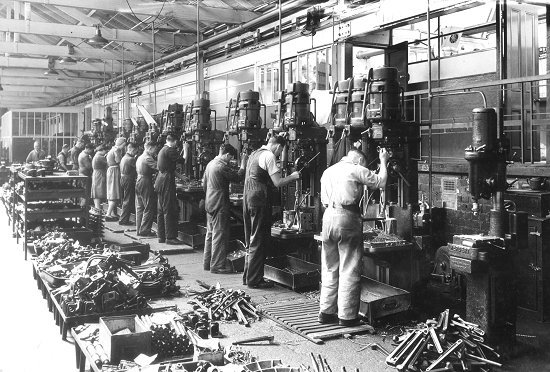

The radial driller section, top floor. In the centre are pillar

drills with swinging arms. On the far left are light drillers. In the foreground two inspectors are checking a component. |

|

This is the same section on a different

occasion. |

|

Machine shop (top

floor), light drillers section. In the raised area behind the

machines are the foremen's offices, the

work's barber shop, and a ladies' rest

room. |

|

Hardening Shop, heat treatment furnaces. The foreman in the

middle of the photo is George Dyson. He was noted as an avid

fan of Hank Jansen's western novels, copies of which he always

had around the works. |

|

Another view of the Hardening Shop. Hardening was done by a

variety of methods, including oil hardening and cyanide

hardening. |

|

The Service Department. |

A final view of the factory.

|

|

|

|

|

Return to

The End of Guy Motors |

|

Return

to the

beginning |

|

Proceed to

Images of Guy Vehicles |

|