| Expansion Several important changes

took place in 1920. The Fencing Department closed, and

the Metal Aircraft Department was formed. At the same

time the Roofing Department became the Structural

Department, and on April 14th the name Rubery, Owen &

Company Limited was registered. The company was

registered at the suggestion of the Midland Bank and

Alfred Owen's accountant, in order to look after his

investments, the assets of which would be transferred to

the new company. By that time he had invested in the

Darlaston & District Housing Association, Chains Limited

at Moxley, Nuts & Bolts (Darlaston) Limited, A. G.

Sutherland Limited in Birmingham, and Rogers & Jackson

of Wrexham.

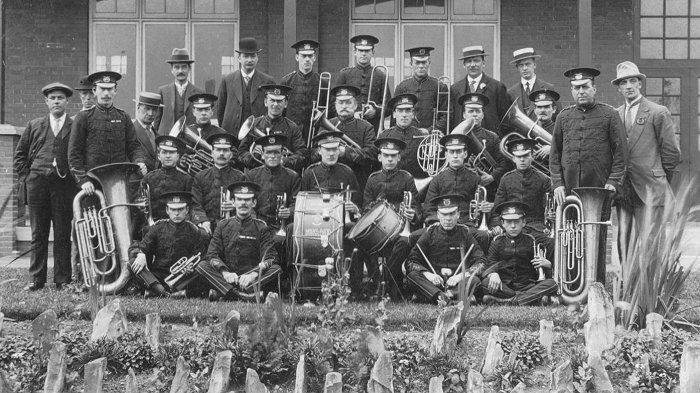

The company's brass band, the

Victoria Brass Band. From an old postcard.

The 1920s were a time of ups and downs. The post-war

recession in the early 1920s caused severe financial

problems in a rapidly declining market. There were

difficulties in reducing costs in order the keep the

firm competitive. The departmental managers were not

able to achieve the necessary cost reductions, and so

drastic action was necessary. In 1923 all factory

employees were given a week's notice, and only essential

staff were re-employed, at rates of pay the firm could afford.

This was organised by the Company Secretary, George

Buckley, who ran the Central Office, and the Accountant,

Charles Partridge who was in charge of the Financial

Department. In order to carry out their task they were

appointed as Joint General Managers. |

| The product range was extended to include the

manufacture of metal aircraft propellers, pressed steel

shafting pulleys, for overhead line shafting, and the

opening the Motor Wheel Department to produce vast

numbers of disc and wire wheels. In 1923 Alfred Owen

bought New Hall Manor in Sutton Coldfield as his family

home. The house, claimed to be one of the oldest

inhabited moated houses in the country, had a sizeable

estate, which was run by his wife Florence.

In the next year, Alfred underwent an operation for an

internal complaint from which he had suffered for

sometime. During his absence the firm was ably managed

by the Joint General Managers, George Buckley and

Charles Partridge, both long serving employees. The

operation was a great success and he resumed to his

labours with renewed vigour.

By the late 1920s the business had fully recovered

from the recession and the future looked bright.

Unfortunately, in November 1929, Alfred Owen suffered a

recurrence of his illness, from which he never

recovered. He sadly died on 29th December, 1929, in his

sixtieth year, and was buried at Sutton Coldfield

Cemetery. |

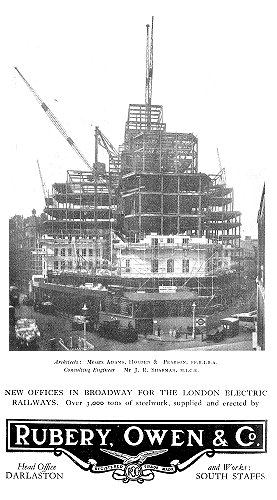

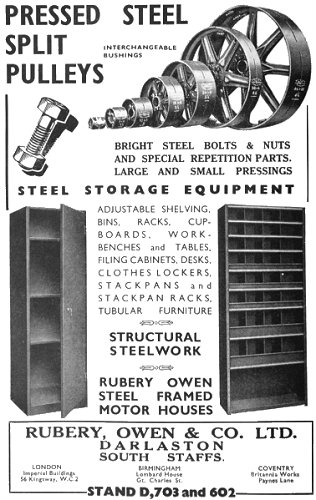

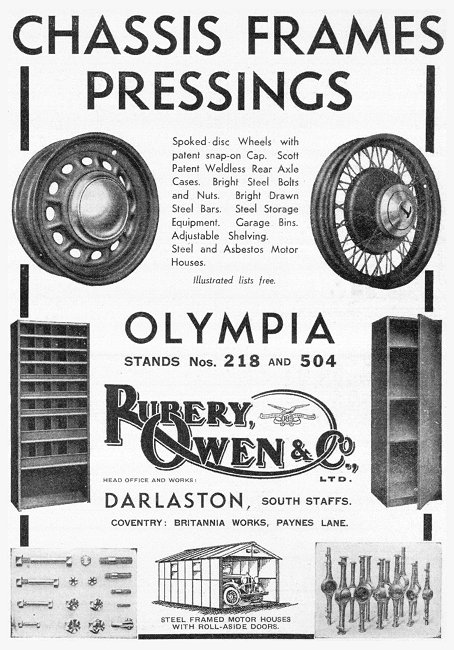

An advert from 1927. |

| It was now time for his two sons to take over. His

eldest son, Alfred George Beech Owen, a 21 years old

engineering student at Emmanuel College, Cambridge took

over the business on 2nd January, 1930. At the time the

firm had 1,600 employees. In 1934 A. G. B.

Owen and his younger brother, Ernest William Beech Owen

became joint managing directors.

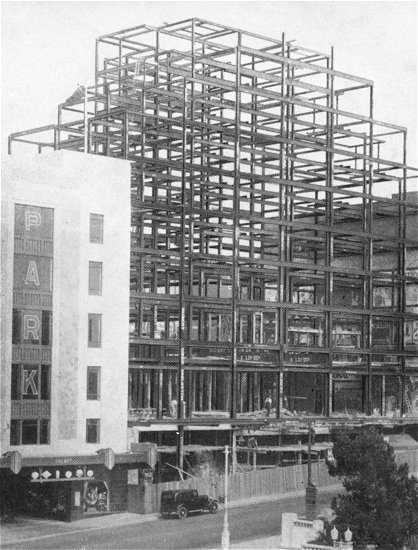

The Structural Steel

Department |

An advert

from 1930. Courtesy of Mike Ashworth. |

In the 1930s the Structural Department provided the

structural steel for a number of stands for some of the

country's leading football teams including Derby County,

Manchester United, Millwall, Twickenham, and

Wolverhampton Wanderers.

Steel structures were designed and made for

all types of single and multi-storey buildings, and erected by Rubery Owen in conjunction with the customer's architect or

civil engineer.

The firm’s structural department was responsible

for a number of well-known buildings such as the London

Passenger Transport Offices at Westminster (the tallest building

in London at the time); the Palace Court Hotel, Bournemouth; Rootes

Securities building; Speke aircraft factory; the Castle

Bromwich aircraft works; Tube Investments factory;

British Celanese factory; the Austin factory; and the

Bush Radio factory.

Local structures include the

steel frame for Wolverhampton's Civic Hall, and Birmingham

Tramways and Omnibus Department's bus garage. Many

steel structures were built during the Second World War,

including shadow factories, aircraft hangars, and store

depots, which were built to the requirements of the War

Office, while during the months previous to the Second

Front, contracts for Bailey bridges, frigate components,

tank landing craft, lock gates for Flanders canals,

steel lifeboats, and components for Mulberry Harbours

were carried out in strict secrecy. |

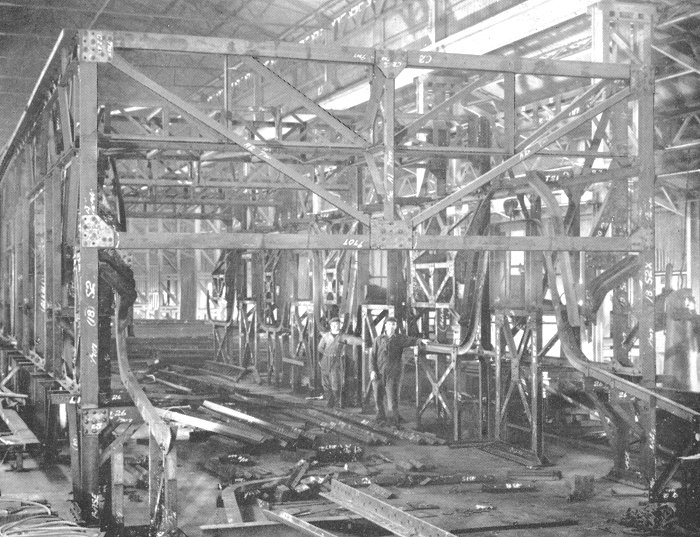

An inside view of a large aircraft

factory built by Rubery Owen in the late 1930s, which

used over 12,000 tons of steelwork. |

| In 1945 Hudson Brown Limited in Oldbury, became part

of the Owen Organisation. The company, which had been

founded in 1937, manufactured structural steelwork, and

carried out the same kind of work as the structural

steel department. They became part of the department,

and produced steelwork for garage buildings, bridges, and

specialised plant equipment. |

A view inside the Hudson Brown

factory, showing the construction of structural steelwork

for a roto-dip plant that was built for Volvo, and

exported to the Volvo factory in Sweden. |

| Assembling the steelwork was

both a difficult and dangerous job.

In the 1950s there were no

helmets, harnesses, or safety ropes available. |

|

|

A modern hotel at Bournemouth. |

Some of the many other welded structures

fabricated at the Darlaston factory included single and

multi-storey buildings of all kinds, such as hotels,

cinemas, hospitals, banks, blocks of flats, offices,

complete factory buildings, warehouses, power stations,

bus depots, garages, and bridges.

Members of the design staff also

operated in London, Birmingham, Coventry and

Southampton, to assist architects, engineers, municipal

authorities and other clients.

|

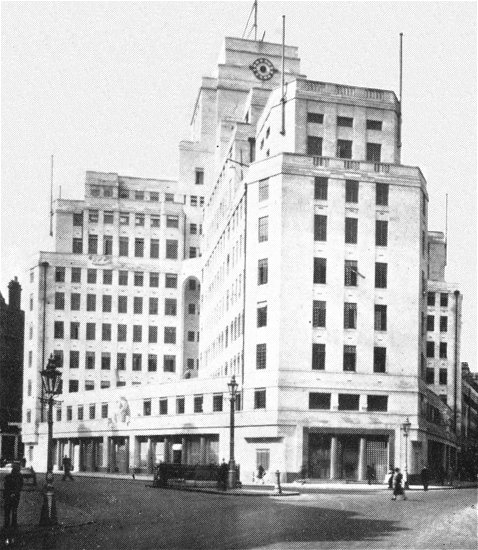

| The headquarters of the London

Passenger Transport Board, over St. James's Park

Underground Station. It has changed little today.

At the time, the 14 story building

was the tallest building in London.

Over 3,000 tons of structural

steelwork were used in the construction of the building. |

|

| After the war, houses were in short supply, and local

authorities had to start vast council house building

programs to meet the demand. The Structural Department

produced a range of pre-fabricated houses to be

sold to local authorities. They were designed by A. T. &

Bertram Butler of Wolverhampton. |

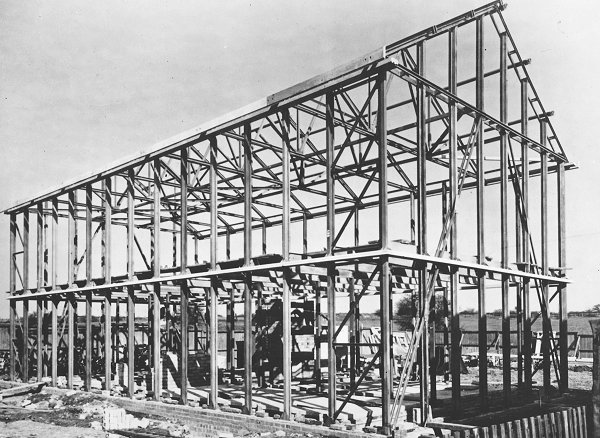

The first page of the Rubery Owen

catalogue.

A Rubery Owen house. From the firm's

catalogue.

The same house under construction. From

the firm's catalogue.

The steel framework. From the firm's

catalogue.

From the firm's catalogue.

From the firm's catalogue.

A Rubery Owen house today.

Another Rubery Owen house.

|

Working on an 84 ft. long

steel girder in the Structural Department in the 1950s.

Courtesy of Christine and John Ashmore. |

| A. G. B. Owen was as

much a businessman as his late father, and soon plans

were made to expand production. In 1932 he opened the

Metal Storage Equipment Department. In 1937, as war with Germany

seemed more likely, and rearmament began, he opened the

Armour Plate Department, to produce armour plate

assemblies for tanks and gun turrets, and also the Metal

Aircraft Department in 1939 to produce parts for air

frames. The Metal

Aircraft Department

Metal components of all kinds were produced in

the Metal Aircraft Department. Initially aircraft

propellers were made, but the project range eventually

expanded to parts for the company's vast range of

products. During the Second World War, special petrol

containers known as 'Jerricans' were produced along with

steel helmets, smoke containers, ballistic caps,

incendiaries, mortar shells, anti-tank ammunition, and

shell carriers. |

|

One of the large press shops

in the Metal Aircraft Department. |

| Stove enamelling fluorescent

light fittings. |

|

|

In 1946 the Metal

Aircraft Department became the Metal Assemblies

Department and used its deep-drawn presswork for a

variety of products, including brake drums, engine sumps,

valve covers, sheet metal products in aluminium, dural,

alclad and stainless steel, and an extensive range of

components for domestic appliances, cookers and

refrigerators.

Other products

included sink units, washbasins and flushing cisterns,

all produced in enamelled steel in one of the finest

vitreous enamelling plants in the country. Sinks,

washbowls, milk churns and dairy equipment were also

made from stainless steel, and thousands of fluorescent

lighting units were made to customers' designs. The

department also made propane and butane gas cylinders

for the petroleum industry, at a branch factory in West

Bromwich. |

|

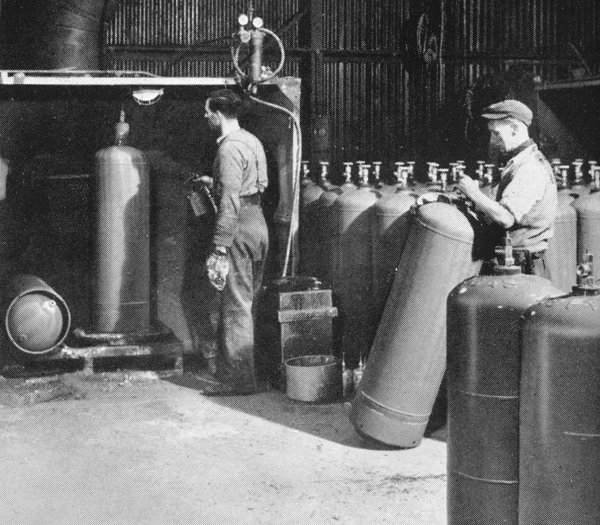

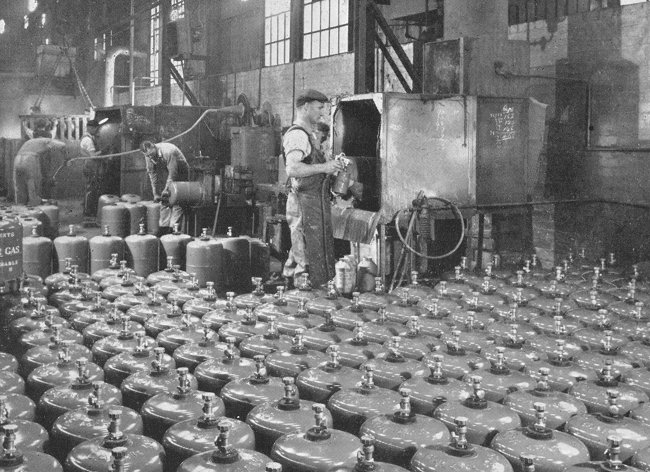

Producing large industrial

propane and butane gas cylinders. |

|

Producing smaller domestic propane

and butane gas cylinders. |

|

|

|

|

Two

adverts from 1938. |

|

An advert from

1936. |

In 1938 A. G. B. Owen became Chairman, and acquired Easiclene Porcelain-Enamel (1938)

Limited, which had been in liquidation, and also opened

a Cooker Department in Coventry. In the

following year Rubery, Owen & Company Limited obtained

control of Aviation Engineering (Messier) Company

Limited at Warrington where the undercarriages for the

Handley Page Halifax Bomber were made. Its name was

changed to Rubery Owen Messier Limited on 17th July,

1939.

During World War II the company turned out all kinds

of products to assist in the war effort, including wing

flaps, ailerons and tail units for Lancaster bombers,

parts for the De Havilland Mosquito, aircraft propeller

hubs, aircraft wings, lifeboats, sea mines, bombs,

armoured car bodies, Bofors guns and howitzers, Bailey

bridges, 'jerricans', and even large quantities of steel

helmets. |

|

|

In January 1943, the Duke and

Duchess of Gloucester paid a visit to the Darlaston

factory, as did Sir Stafford Cripps, Minister of

Aircraft Production, in February, 1944.

In order to fulfil orders for the Admiralty,

the Warrington company's engineering department was

turned into a separate company. By the end of the war

the firm employed around 16,000 people and the future

for peacetime products looked extremely bright.

The Motor Frame

Department Since its opening in 1904, the Motor

Frame Department became one of the company's most

important sections, providing the county's ever

expanding motor industry with pressed steel chassis, and

pressed automotive parts. During the Second World War,

the department produced a wide range of components for

military vehicles, carriages for 2 to 25 pounder guns,

carriages for 4.5 to 95 mm guns, Bofors gun platforms,

armoured car turrets, Bailey Bridge parts, ammunition

boxes, searchlight gear track units, and sand channels,

all for the Ministry of Supply. The department also

supplied the Admiralty with mines, powder cases, and

projectiles; and the Ministry of Aircraft Production

with storage racks, universal jacking trestles, bomb

trolleys, and 250 lb. bombs. After the war, pressed

steel chassis were produced in many forms, for cars,

light commercial vehicles, and buses. They could be up

to 36 feet in length. Another product was 'Scott' patent

rear axle casings for light commercial vehicles and

cars. Hundreds of thousands of them were produced

directly from steel tube, on special hydraulic machines,

so that they were entirely weldless. |

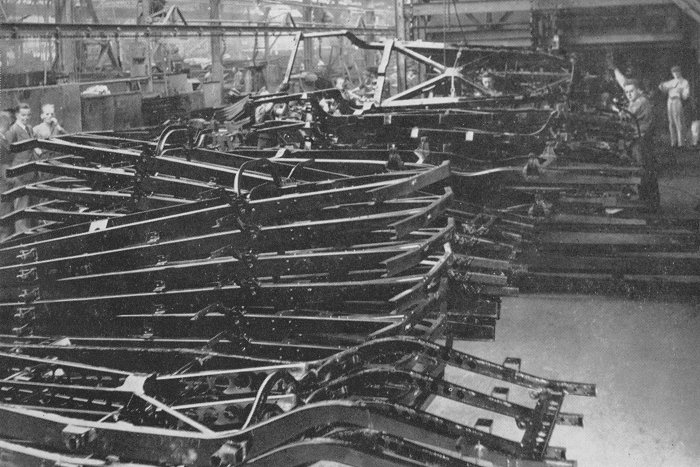

|

Completed chassis frames. |

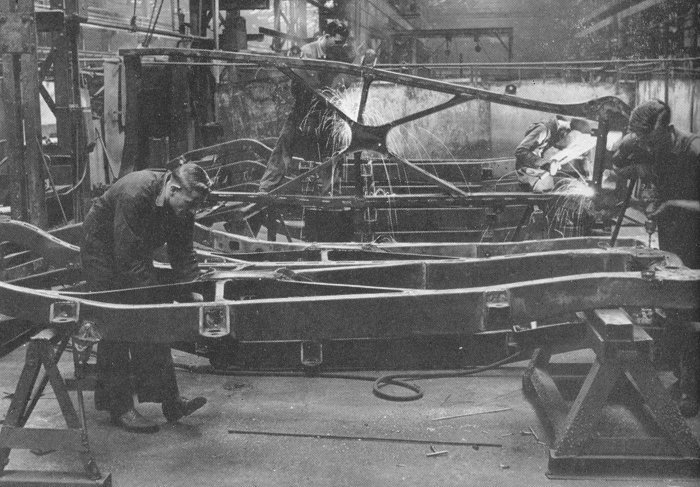

|

Building chassis frames in one of

the large erecting shops. |

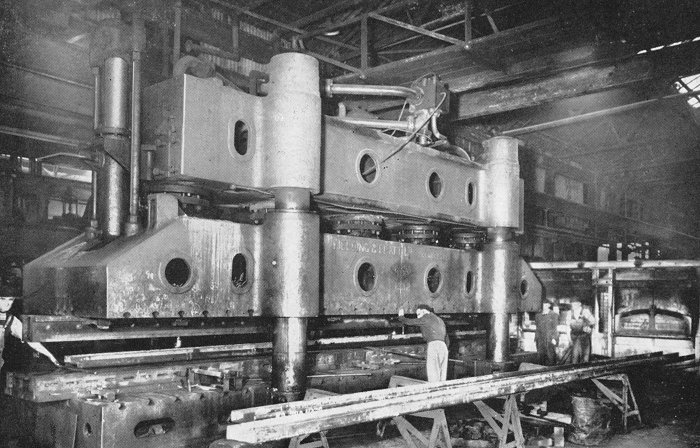

| The department had two large press shops, one for

cold pressings up to ¼ inch

thick, and one for hot pressings up to ⅝ inch thick.

Both press shops had a range of presses from 30 to 2,000

tons, and produced products for the automotive and

general engineering industries, as well as complete

fabrications, and large deep drawn pressings. |

|

A hydraulic press, turning out

parts of bus and lorry chassis. |

|

Dipping chassis frames as part

of the enamelling process. |

| The department's toolroom was one of the largest

in the Midlands. It produced all of the large press

tools and jigs for the press shops, which were

designed in-house. There was also a motor repair

section in Meeting Street, Wednesbury, which undertook repairs to

chassis and rear axle casings. It catered for local

garages and service stations. |

|

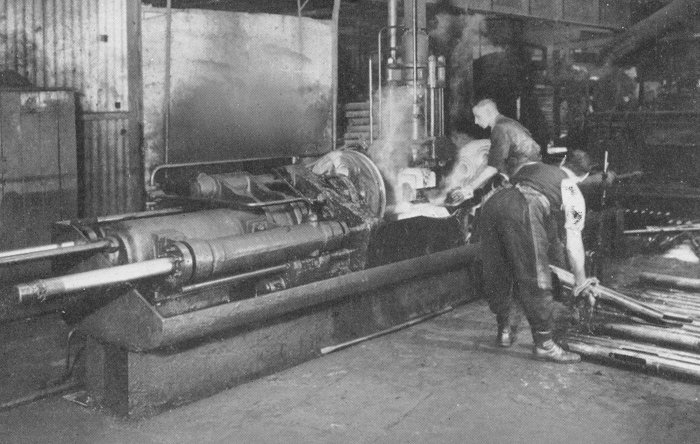

Making 'Scott' rear axle

casings on one of the special hydraulic machines. |

|

An advert from 1949. |

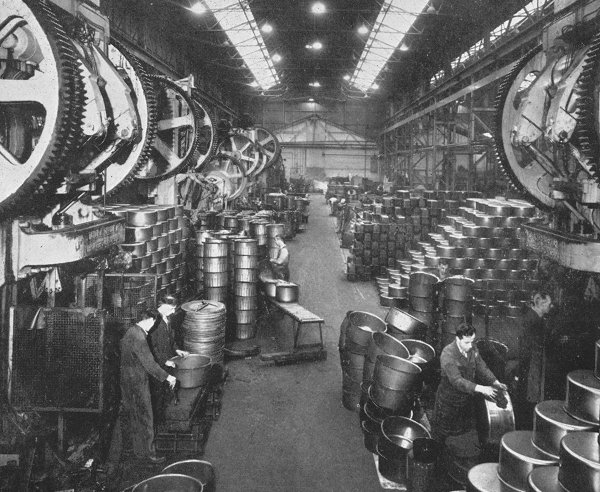

| The Motor Wheel

Department The Motor Wheel Department

supplied pressed steel wheels and wheel discs for

the motor industry, and supplied over one third of

the British vehicle manufacturers with disc and

spoked disc wheels for private cars. Wheels for

caravans and agricultural trailers were also

produced, along with 400 types of steel split

pulleys, ranging from 3 to 48 inches in diameter.

During the Second World War, the department

produced charge cases for demolition purposes, instrument

containers, sea mine trigger mechanisms, aircraft

bomb carriers, ant-aircraft weapon equipment, steel

helmets, and ammunition boxes. |

|

Large scale wheel production. |

An advert from October 1958.

| The Air Frame

Department This department opened in the

Second World War to produce air frame units, wing

flaps, tail planes, assemblies for the Stirling and

Lancaster bombers, 50 gallon jettison tanks for

Spitfires, and light alloy radar reflectors.

After the war the department concentrated on

large scale production of petrol tanks for cars,

commercial vehicles, and agricultural vehicles.

Department No. 11

Another wartime department, Department No. 11,

produced propeller hubs by a new process developed

in conjunction with Messrs. Rotol of Gloucester, and

the Ministry of Aircraft Production. The hubs were

pressed in two halves, direct from steel plate, over

on inch thick, using presses of up to 2,000 tons

capacity. After the war, the department produced two

piece, pressed steel, rear axle casings, for

commercial vehicles. |

|

Flash welding petrol

tanks. 5,000 types

were produced each week, all fully assembled and

tested. |

| Aviation

Department The Aviation Department opened

before the First World War for the production of

repetition components machined to fine tolerances,

in all metals. Bright drawn steel bars of various

sections were also produced. By the 1940s, around

five million parts were manufactured in the

department, each week.

After the Second World War, the department was

manufacturing bright bolts and nuts up to one inch

in diameter, eye bolts, turn buckles, shackle pins,

and tension rods for the motor, aircraft, and

general engineering industries. They were produced

in mild steel, high tensile steel, and alloys, and

were available in a wide range of finishes,

including cadmium, and zinc, and could be Parkerised,

or anodised.

Cold-headed, heat treated bolts were also

produced, and were available in mild steel, high

tensile steel, or nickel steel, in sizes from 2BA up

to half an inch in diameter, and six inches long.

Bright steel bars up to 2¼

inches diameter were also produced. |

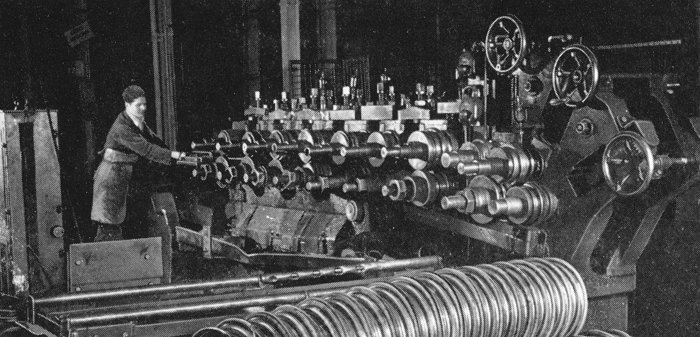

| Part of the production

area, where precision aircraft parts, and bright

bolts and nuts were made. |

|

|

A few of the many small

components manufactured in the department. |

|

The department's other factory

at Moxley, where cold headed bolts were produced by

the million. |

| The Aircraft

Components Department This department

opened in 1939 to manufacture precision sub

assemblies, and small accessories for aircraft

manufacturers. Products included control columns,

seats for pilots, rudder bar assemblies, and

hydraulic feed systems. The product range later

widened to include valves for propane and butane gas

containers, valves for small hydraulic rotary pumps,

and valves for petrol nozzles, and hydraulic jacks.

New production lines were laid down to manufacture

agricultural components, particularly the hydraulic

implement lift for the Fordson 'Major' tractor.

Other products included axles for caravans and

agricultural trailers, with a loading capacity of 12

to 60 cwt. |

|

Assembling hydraulic implement

lifts for the Fordson 'Major' tractor. |

| Agricultural Plough Department This was

originally established in 1937, as the Armour Plate

Department, to manufacture armour

plate assemblies for tanks. After the war,

production turned to implements for the Ferguson

tractor, including the Ferguson plough, the Ferguson

universal grain drill, the International

Harvester manure spreader, and beet hoppers. Accessories and

components were also produced for various types of

agricultural implements. |

|

Completed ploughs. |

| The Metal

Equipment Department |

|

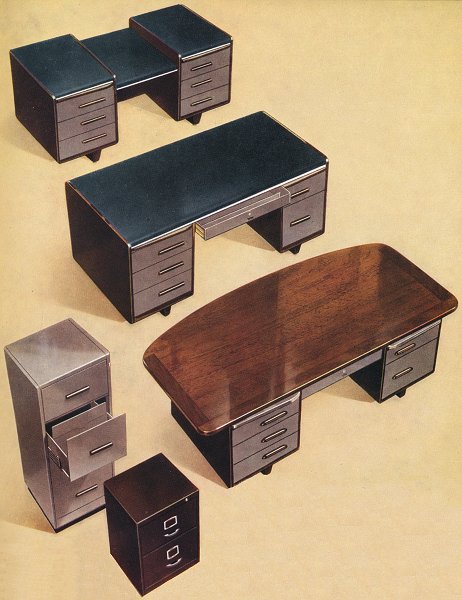

The department opened in 1929 to manufacture all

kinds of metal storage units and steel office

furniture. They were supplied to factories, and

government departments at home and abroad, The

department rapidly expanded, and a new factory, The Whitegate Factory, was acquired at Wrexham in order

to increase production.

The Wrexham factory concentrated on storage

equipment, and the department at Darlaston

concentrated on office furniture.

The office furniture included filing cabinets,

and a wide range of desks and tables. The desks

could have a lino top, or one made of oak, or

mahogany.

There were also wardrobes, typists' desks and

tables, cupboards, and plan files for design

offices,. The department also manufactured kitchen

cabinets, refrigerators, and special purpose control

equipment. |

| An example of the special

purpose control equipment that was manufactured at

Darlaston.

A piece of flight control

equipment that was supplied to the Ministry of

Civil Aviation. |

|

|

The Darlaston Factory. |

| A. |

Invicta Electrodes Limited |

|

L. |

Laboratory |

| B. |

Apprentice Training Centre |

|

M. |

Aviation Department |

| C. |

Aircraft Components Department |

|

N. |

Structural Steel Department |

| D. |

Air Frame Department |

|

O. |

Metal Aircraft Department (Press Plant) |

| E. |

Vitreous Enamelling Department, and

Easiclene |

|

P. |

Motor Frame Department |

| F. |

Department No. 15 |

|

Q. |

Axle Case Department |

| G. |

Heavy Press Plant |

|

R. |

Agricultural Implement Department |

| H. |

Motor Wheel Department |

|

S. |

Transport Services |

| I. |

Metal Equipment Department |

|

T. |

Technical Administration |

| J. |

Department No. 46 |

|

U. |

Central Administration |

| K. |

Motor Frame Department, Hot Pressing

Plant |

|

V. |

Sheet Metalwork Department |

|

|

|

|

|

Return to

The

Early Years |

|

Return to

the contents |

|

Proceed to

Easiclene |

|