F. H. Lloyd & Company

Limited - The Later Years

|

|

The company's first computer. |

| In 1970 an IBM System 360, Model 25 computer was

installed at James Bridge Works. The machine, which cost

£150,000 helped to rationalise production by monitoring

the progress of each order from the initial enquiry to

despatch. It also improved production control, and

assisted with the provision of management information.

Once it had proved itself, it handled the payroll for

most of the group's workforce of 7,000, took over stores

control, handled purchases, and provided sales analysis

and cost accounting data.

It had a CPU with 24,576 bytes of core storage, three

IBM 2311, 7.25 MB hard disc drives, a printer with a

keyboard, a line printer, and a card reader. Although

very high tech for 1970, it is extremely basic by modern

standards. |

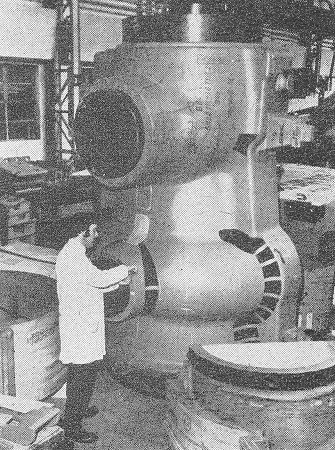

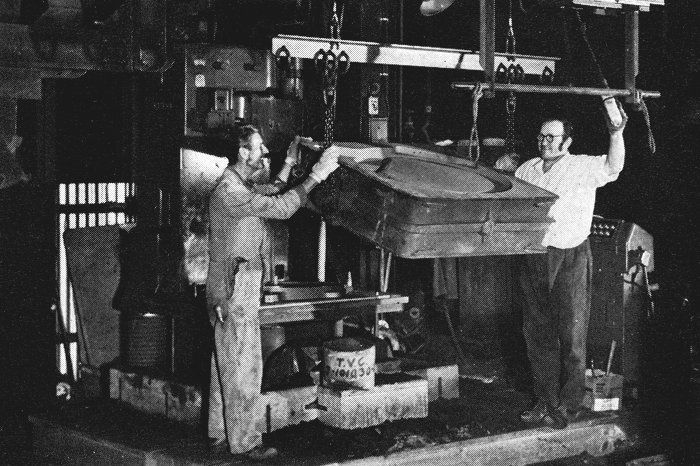

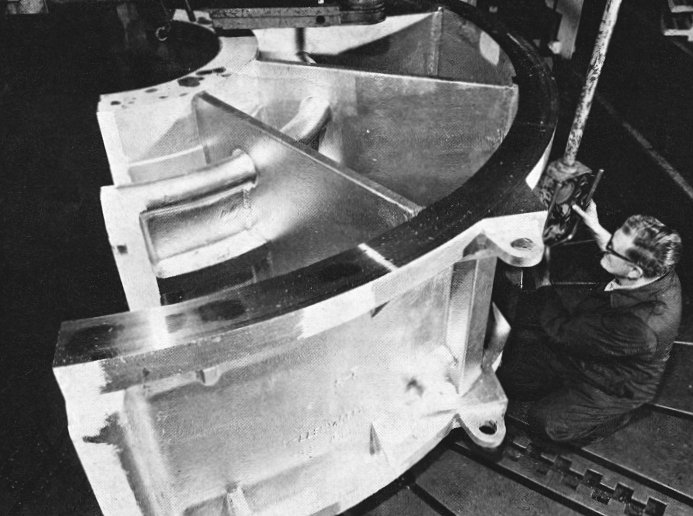

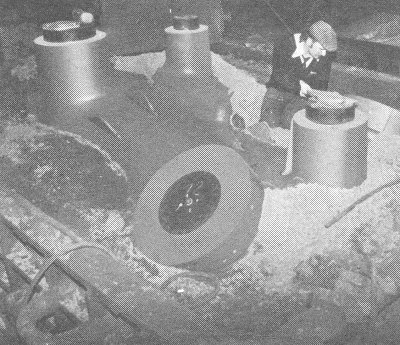

Lloyds produced almost an infinite variety of steel

castings including the ones above, which were produced in

the late 1960s at James Bridge. They were cable glands

for the Pierre Laporte parallel-wire suspension bridge

at Quebec, the first of its kind in Canada. 174 of them

were produced, all with an internal diameter of 24½

inches. The order was valued at £70,000. |

|

A view of the Machine Shop

from 1970. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

An

important department at James Bridge was the F.H.L.

Medical Centre which had extensive facilities to deal

with all kinds of injuries sustained in the James Bridge

factory. It was also used by some of the local factories, and

Wednesbury Technical College, thanks to various

agreements.

The centre could cope with a wide range injuries from

a piece of grit in the eye, to molten metal burns,

welding flash, alkaline burns, lime burns, and acid

burns. Every employee had an X-ray on joining the

company, and every 12 months had to have a check-up in

the medical centre. Weight, height, teeth, and eyesight

were checked, and medical records were kept.

Inoculations and vaccinations of all kinds were given,

particularly to members of staff about to travel abroad

on company business.

The centre had its own chiropodist in the form of

Joyce Treadwell, and later Miss Kidney. Surgery was

carried out on three afternoons each week by Dr. Baker,

or Dr. Pollett. There was also a well-equipped

physiotherapy room complete with sunray lamps, infra-red

lamps, massage equipment, and a variety of home nursing

equipment that could be loaned to employees.

Some employees had to wear respirator masks as part

of their job. There were four women in the centre who

were kept busy cleaning the masks so that a clean supply

was always available. There were two masks for each

employee, one for wearing, and one for cleaning. Sister

Powell was in charge of the centre for around 30 years. |

|

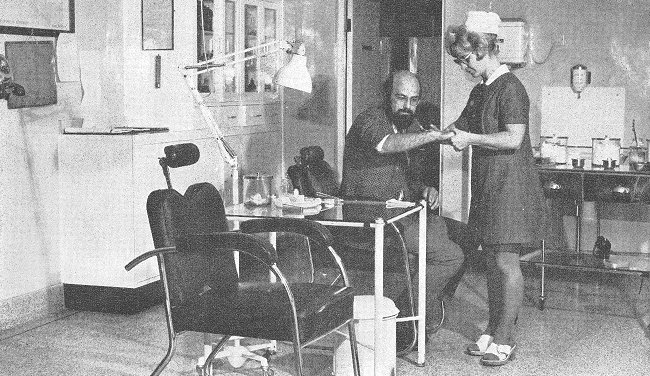

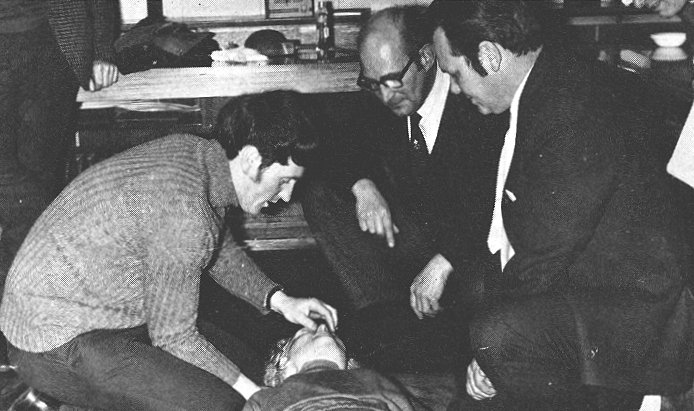

Sister Chin treating a patient in

the men's general surgery. |

|

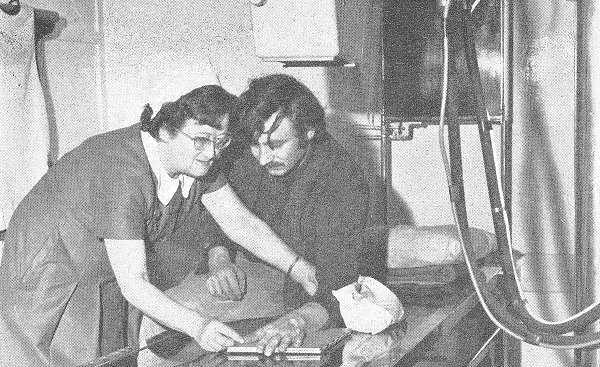

Sister Powell prepares a

patient for an X-ray. |

| Sister Powell applies eye

drops to a patient. |

|

|

Sister Powell with her

retirement presents in 1974. From 'The Steel

Casting', courtesy of Wendy Marston. |

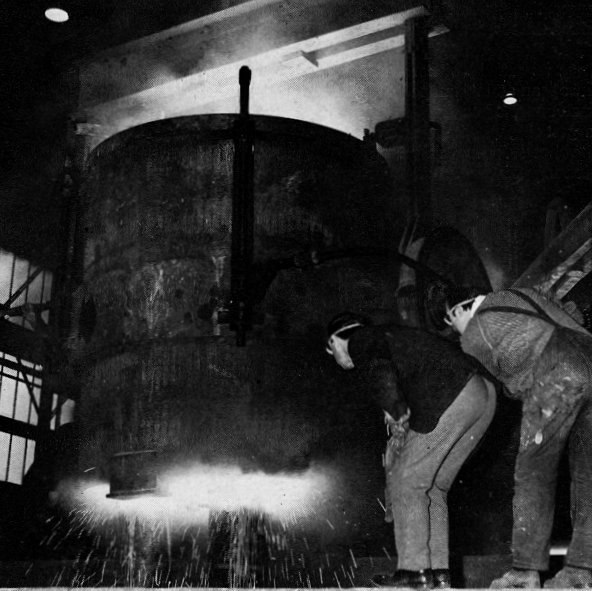

Casting a 'Supertherm' heat resisting steel alloy tube

at Lloyds (Burton) Limited. Part of an order worth

£100,000 for a Japanese company. |

| A new company in the Lloyds group was created on 5th

April, 1971 as the result of a merger between two

members of the John Bagnall sub-group. It was called

Lloyds (Brierley Hill) Limited and came about when The

British Tayco Chain Company Limited merged with W. G.

Electrical Welding & Engineering Company Limited. Tayco

steel chain cable had been made for many years, but

production ceased due to lack of demand. The new company

would concentrate on the production of 'Blaco' stud

steel chain cable, and open link chain, suitable for

marine moorings, heavy industrial slings, and railway

couplings. |

|

An advert from 1974. |

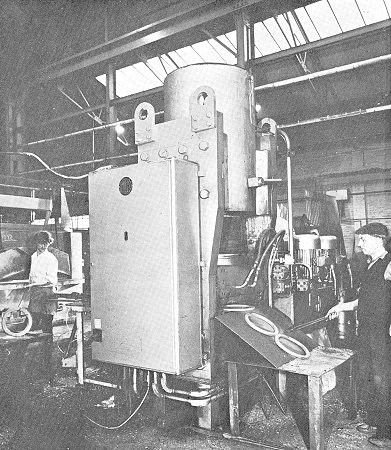

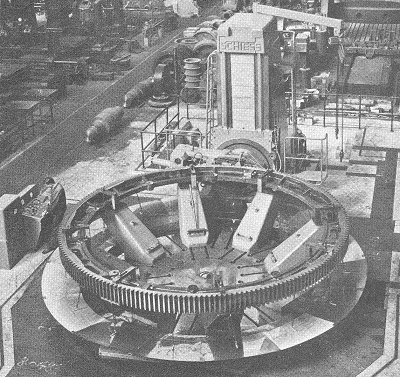

The 500 ton hydraulic press

installed at Brierley Hill to produce engine-starter

rings for commercial vehicles. |

A new plant was installed at

Brierley Hill to produce commercial vehicle starter

rings.

Around 22,000 rings could be

produced per week. 15 percent of them were fully

machined, gear cut, and induction hardened. |

| In 1973 orders included a number of turbine

castings for the CEGBs 500MW Ince power station at

Ellesmere port. The order for £118,000 of castings

included a pair of intermediate pressure outer

casings and three pairs of lower pressure casings.

In 1972 the Directors decided to restructure the

company to bring about more effective coordination

of marketing programmes, production techniques,

research technology, and to improve inter-company

communications. In order to achieve this the

companies were grouped into three divisions;

engineering, foundry, and steel. The restructuring

was announced in December 1972 by Mr. M. C. Lloyd.

|

|

Mr. Michael Charles Lloyd,

1909 to 1973. From 'The Steel Casting', courtesy of

Wendy Marston. |

|

Michael Charles Lloyd – A Tribute. From

the 'Steel Casting' February, 1973.

Michael Charles

Lloyd was a man whose objective was to

serve his community, his business and

his industry to the best of his

abilities. That he served well will be

immediately acknowledged by all who knew

him. Such acknowledgement perhaps

provides an epitaph which he would have

considered fitting.

He succeeded his

brother Frank as Chairman of F. H. Lloyd

Holdings Limited in 1971. From the date

of his appointment he was concerned to

reinforce the executive management of

the Group and to provide for succession

of management against the time, in 1975

when he was due to retire. He

relinquished the position of Group

Managing Director and set up a Group

Executive Committee to undertake the

functions of corporate planning, policy

initiative and co-ordination of company

activities.

Under Mr. Lloyd's

Chairmanship, this Committee has made

substantial progress in streamlining and

re-organising the F. H. Lloyd Group,

particularly in re-structuring its 21

operating companies into three main

Divisions: Foundry, Steel and

Engineering. This restructuring marks a

watershed in the development of the

Group, and Michael Lloyd's role in

bringing it about was central.

His contribution to

industry in general and to the steel

foundry industry in particular, was

considerable. Over the years he held

various offices with the Steel Castings

Research and Trade Association, was a

member of the Council of the Production

Engineering Research Association and a

member of the Council of the

Confederation of British Industry.

Appointments of this kind were important

to Michael Lloyd only in terms of the

contribution he could make: he was never

a man to accept a position for the

status such acceptance might provide.

Where he felt he knew his subject well

enough to enter into public debate he

did so with a vigour and clarity of

expression that made his a voice to be

listened to.

His work in this

area was recognised in 1960 when he

became a Member of the Order of the

British Empire, specifically for work on

the Midlands Industrial Advisory

Committee to the Chairman of NEDDY. At

his home in Hilton House, Bridgnorth,

Shropshire, he lived a quiet family life

with his wife Priscilla Mary, son Dan

and daughter Penelope. His other

daughter, Charlotte lives in South

Africa.

The grounds of

Hilton House contain one of the two most

important (after his family) of his

non-business interests, the Hilton

Valley Railway, famous among miniature

railway enthusiasts both in this country

and abroad. This railway gave, as it

continues to give pleasure to thousands

of visitors, many of whom were driven by

Mr. Lloyd. He was the drive behind the

success of the railway and the proceeds

of that success were invariably donated

to local charities. The railway,

however. was a hobby: the part he played

as a member of the congregation at

Worfield Parish Church was the bedrock

of his life. He was organist at the

Church for many years, and a good one.

It can truly be said that he was a

pillar of the church and his community.

Mr. Lloyd was born

in Wolverhampton on August 6th 1909. He

was educated at Lambrook Preparatory

School, at Charterhouse School and at

Birmingham University. His life was long

and full; his death was tragic and

premature. |

|

Members of the first first aid

course. Left to right: Lynne Marsh, Buying Dept; Dr.

Lester, and Jack Casey, Pattern Shop. From 'The

Steel Casting', courtesy of Wendy Marston. |

|

First Aid Course

After discussions

in the Management/Joint Works Committee

a first aid course was arranged by the

company for employees wishing to qualify

for a first aid certificate. Thirty

employees started the course on

Wednesday, 21st February, 1973, and 23

completed the course and took the

examination in April, which they all

passed, and received a certificate from

the St. John Ambulance Association.

The course

consisted of eight, two-hour lectures

with two one hour revision sessions. Dr.

J. P. Lester gave six lectures on the

theory of first aid which included the

principles and practice of first aid

structure and the functions of the body,

resuscitation, shock, injury to bones,

poisoning and the nervous system.

There were eight

practical sessions given by two of the

employees, George Sterry of the

Inspection Department and Jack Casey of

the pattern shop. George is divisional

superintendent of the Coseley and

Bilston Brigade and Jack Casey is a

qualified instructor. The practical

instruction consisted of the method of

bandaging various injuries from a

fractured spine to minor bleeding,

resuscitation, control of bleeding,

transporting injured persons, and

general welfare of the patient.

The names of first-aiders

were posted in each department so that

they could be called on in emergencies. |

|

George Sterry, centre,

instructing Ken Liddington, left, from the Drawing

Office, on resuscitation, with Harry Bowdler looking

on. From 'The Steel Casting', courtesy of Wendy

Marston. |

|

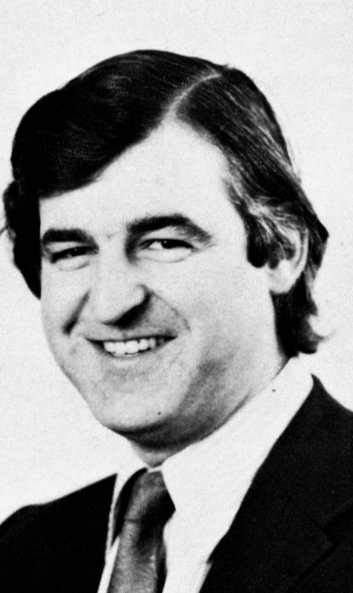

Mr. D. L. Carrier who

became Chairman of F. H. Lloyd Holdings Limited

after the death of Mr. M. C. Lloyd.

From 'The Steel Casting',

courtesy of Wendy Marston. |

A plan of the Wednesbury site in November

1972.

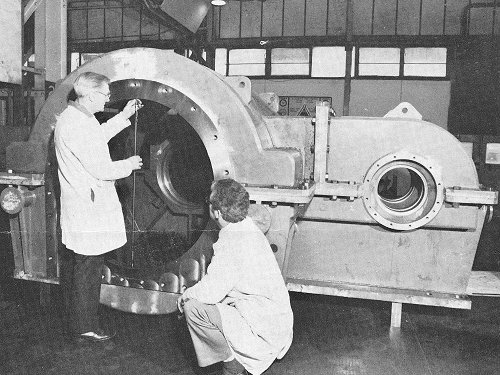

| In 1971 a trial

order worth £18,000 was placed by Brown Boveri for two

turbine castings weighing ten tons each.

The photo on the right shows the

turbine pattern being inspected for Brown Boveri. |

|

|

Inspecting a turbine gear

housing produced at Lloyds for 43,000 ton bulk

ocean-going carriers that were built in Australia.

The unit would house an epicyclic

gear train that carried power from a gas turbine to the

propeller. |

|

Tapping a ten ton furnace. Courtesy of Wendy Marston. |

|

Mr. Francis Nelson

Lloyd, 1907 to 1974.

From 'The Steel

Casting', courtesy of Wendy Marston. |

|

A tribute to Mr. F

.N. Lloyd

Mr. Francis

Nelson Lloyd, former Group Chairman

and Managing Director, died at his

home in Tettenhall, Wolverhampton,

after a period of uncertain health,

on 27th June, 1974, at the age of

66. He retired at the end of 1971,

and so only had a short retirement.

Mr. F. N. Lloyd

was born on 13th August, 1907 and

educated at Charterhouse, and

Trinity College, Oxford. He was a

grandson of Francis Henry Lloyd, the

founder of the company, which he

joined in 1929, becoming a director

in September 1931 and Managing

Director in November 1941 on the

death of Mr. F. J. Hemming. In June

1949 he became Chairman and held

that office until he resigned on

account of ill-health in September

1970.

At the outbreak

of the Second World War he joined

the R.A.O.C. but was soon recalled,

as his presence at the factory was

considered essential to the vital

part which FHL played in the

country's war effort. Towards the

end of the war the company provided

the management and technical knowhow

to operate the new Ministry Steel

Foundry at Burton-on-Trent. Shortly

afterwards F. H. Lloyd acquired that

Foundry and formed it into Lloyds

(Burton) Limited, the firm’s first

subsidiary company and the beginning

of the F. H. Lloyd Group.

In addition to

his involvement with the Lloyd

Group, Mr. Lloyd was a director of

N. Hingley & Sons from June 1953 and

became chairman of that Group in

January 1959. He was instrumental in

the merging of the Lloyd and Hingley

Groups in July 1966. He was a

director of Lloyds Bank from 1956

and also served on its Birmingham

Committee. He was also a member of

the Management Board of the West

Midlands Engineering Employers'

Association from 1941 until 1971

being President in 1964 and 1965.

Throughout his

career Mr. Lloyd was a leading

member of the Steel Founding

Industry and its representative

associations. He became associated

with the General Steel Casting

Association in the late 1930s when

he served on its Council and was a

member of the Townsend Committee. He

became a member of the Council of

the British Steel Founders'

Association on the formation of that

body, and held office virtually

without interruption until the

B.S.F.A. was wound up in 1967

becoming chairman of the Steel

Castings Association on its

formation in that year. Mr. Lloyd

was the first chairman of the

British Steel Castings Research

Association in 1953 and was largely

responsible for effecting the merger

of B.S.C.R.A. with S.C.A. in 1968

when S.C.R.A.T.A. was formed, and

again he became its first chairman.

He was awarded

the CBE in 1970 for his services to

exports. More recently, in 1973, he

was honoured by the foundry industry

when he was awarded the E. J. Fox

medal by the Institute of British

Foundrymen. |

|

|

|

|

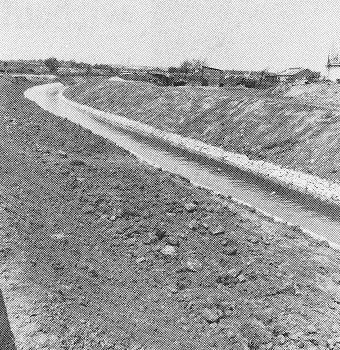

| In 1975

the Severn Trent River Authority decided to

carry out work on the nearby River Tame which

had long been known for flooding, particularly

at the Railway Tavern pub which was sometimes

three feet deep in water. The river was used by

F. H. Lloyd as a source of water for the cooling

and process plant. The work involved

straightening the river and deepening the river

bed. The company decided to to carry out some

work on the river while the alterations were

taking place. A large diameter pipe was

installed from the river to the work's pumping

plant to ensure an adequate supply of water.

When the work was completed, the river was

expected to flood only once every fifty years.

The photographs show the river before and after

the work had been completed. |

Teeming a

multi-ladle job in the Heavy Foundry,

the largest foundry bay in the country.

From 'The Steel Casting', courtesy of

Wendy Marston. |

One of the latest

type of squeeze-jolt moulding machines

at work in the foundry. From 'The Steel

Casting', courtesy of Wendy Marston. |

|

The FHL

switchboard ladies, Dot Davies and Ruby

Johnson.

Dot joined the firm in 1959, and Ruby

joined in 1972.

In 1974 they

moved into a new a new switchboard room

containing some of the latest equipment.

Every year they handled about 200,000

incoming and outgoing calls.

From 'The Steel

Casting', courtesy of Wendy Marston. |

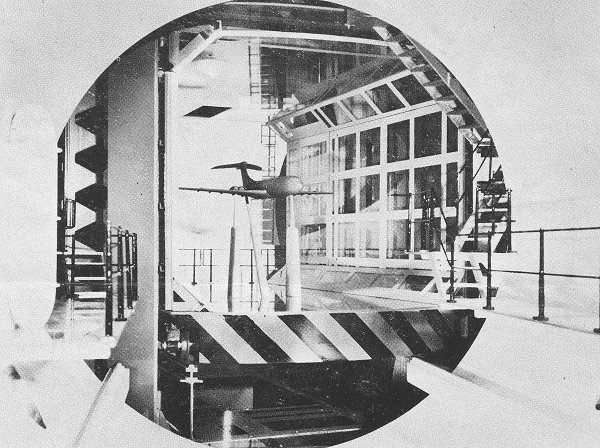

F. H. Lloyd undertook

an unusual and interesting casting job in

1975 for R.A.E. Farnborough. It involved the

production and machining of two large

castings for a low speed wind tunnel. The

two castings, one 22 ft. long, the other 10

ft. long, formed a massive arc upon which

the model aircraft could be mounted within

the tunnel. |

|

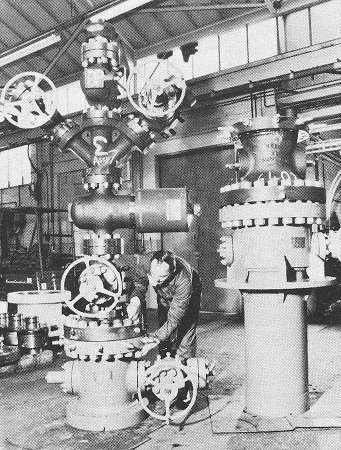

| The exploration for North Sea

oil involved the building of large oil rigs, each with

27 wellhead assemblies, all needing large valve

castings. Each assembly was 17 ft. high and had three

heads, all of which had to be cast and machined.

In 1975 F. H. Lloyd received an

order for castings for 54 wellhead assemblies for use in

the Forties Field, consisting of nearly 180 tons

of castings.

|

|

F. H. Lloyds received many

orders from the North Sea Oil companies including

the breach locks that locked together the 70 ft.

sections to form the oil platform legs. The

photograph above shows the final inspection of a

breach block connector and chaser head by the Chief

Inspector of McEvoy Oilfield Equipment Limited. From

'The Steel Casting', courtesy of Wendy Marston. |

|

A large valve body casting

after being 'knocked-out' from the mould. Courtesy of Wendy Marston. |

|

Valve castings for the oil

industry being machined. Courtesy of Wendy Marston. |

|

One of the North

Sea oil field valve arrangements being

assembled. Courtesy of Wendy Marston. |

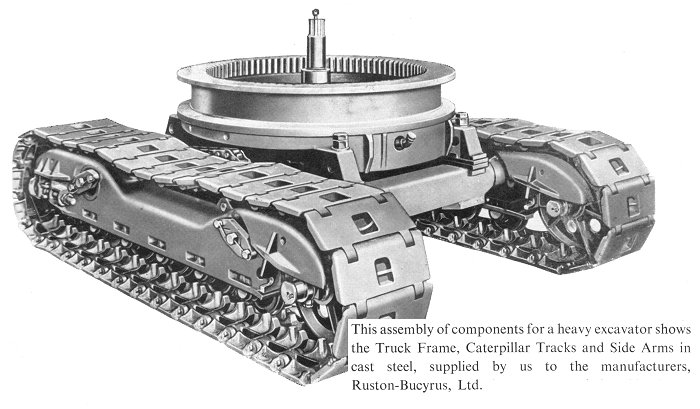

Some of the castings for

excavators that were produced at James Bridge

for Ruston-Bucyrus Limited, one of Lloyd's

largest customers. Courtesy of Wendy Marston. |

|

Hard at work on a

multi-ladle casting job in the foundry. Courtesy

of Wendy Marston. |

|

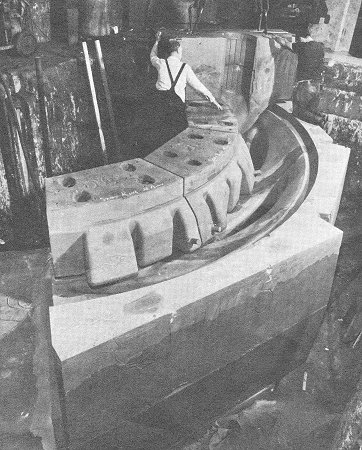

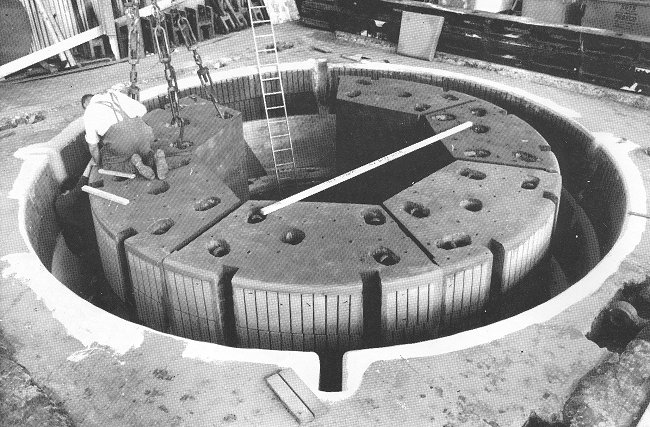

A giant mould for a Dinorwic

Casting. |

F. H. Lloyd supplied many huge

castings for electricity power stations throughout the

world, and made it possible to build some of the largest

power generation units.

One project that relied heavily on Lloyd's castings was

the building of Dinorwic Power Station in North Wales.

|

|

The top half of a GEC 50MW gas

turbine main casing. From 'The Steel Casting',

courtesy of Wendy Marston. |

A patternmaker at work on the corebox for

a stayring for Dinorwic Power Station.

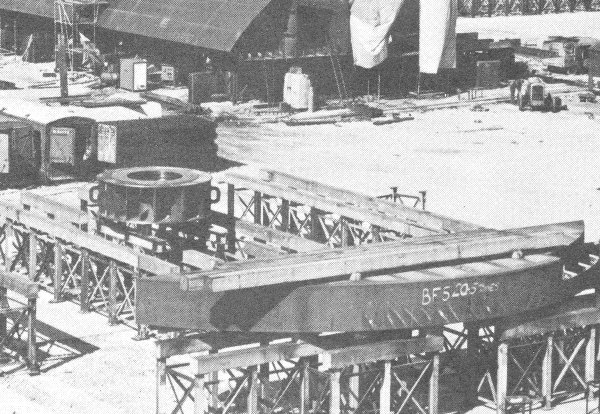

One of the eight massive pivot

bearing castings that were produced by Lloyds for the

Thames Barrier, each weighing nearly 54 tons, with a

diameter of 16 feet. The company produced many castings

for the project including the steel barriers which alone

amounted to castings of over 1,000 tons. |

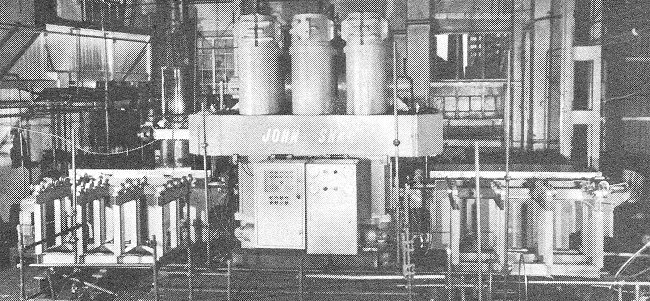

This 71,400 ton rubber die press

built by John Shaw & Sons (Salford) Limited, included

three large castings for the main press head and three

cylinder base castings, all of which were produced by F. H.

Lloyd. In total the castings weighed 61½

tons. |

| A gigantic gear wheel cast by

Lloyds for a cement plant ball mill in Brazil. It had a

diameter of 18 feet and a depth of 2 ft. 6 inches. It

weighed 32 tons. |

|

|

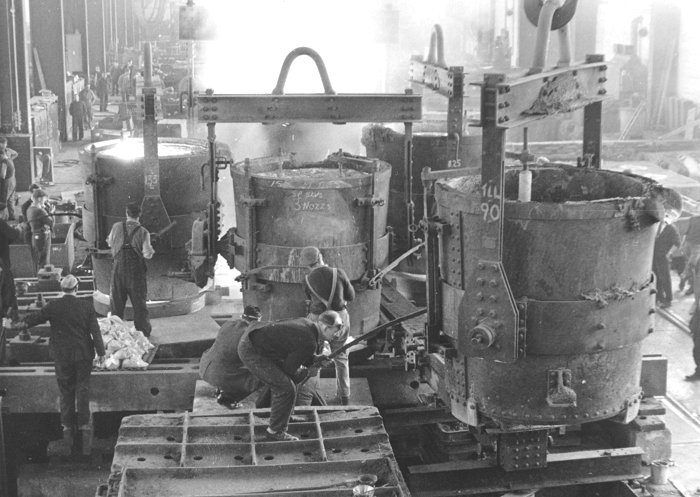

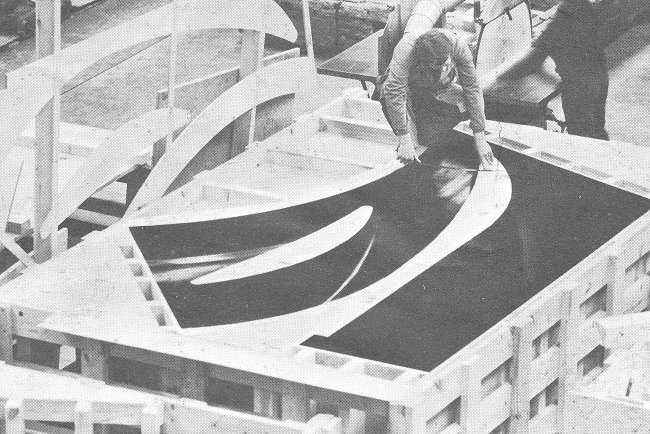

Producing the mould for one of

a series of castings made for Canadian power stations.

In the mid 1970s, Lloyds received orders for over 890

tons of such castings from Canada.

Similar castings were made for

power stations in New Zealand, South Africa, and India. |

The largest cast steel ring

made at James Bridge, left the factory in 1975 to

make its way to Stockton-on-Tees. It was over 18

feet in diameter, weighed over 20 tons, and was

carried on a special tilting trailer, designed for

the purpose. From 'The Steel Casting', courtesy of

Wendy Marston. |

| Lloyds were a major supplier of steel castings to

the large armaments industry, including over one

thousand castings for Chieftain tank turrets. Another,

and very different product produced by the Lloyd Group

was cast steel chain for giant draglines using a

specially developed system of patternmaking, which

resulted in interlocking moulds. The steel could be

poured virtually simultaneously for each link so that

the whole length of chain is cast from the same ladle of

molten steel. Lloyds were one of only a handful of

manufacturers in the world, capable of producing chain

of such a high quality. |

Preparing a mould for a tyre for a

cement kiln, for Head Wrightson Limited,

Stockton-on-Tees. Four tyres were produced and fully

machined, along with one bevel, three straight sides.

Each tyre casting weighed over 96 tons. |

|

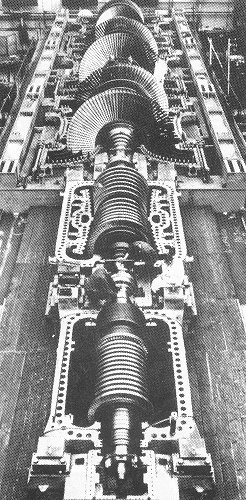

Part of the Drax 'B' power

station built by C. A. Parsons Limited,

Newcastle-on-Tyne. F. H.

Lloyd produced the low pressure castings for thee such

turbines, six for each machine. The total weight of six

castings was 214 tons. |

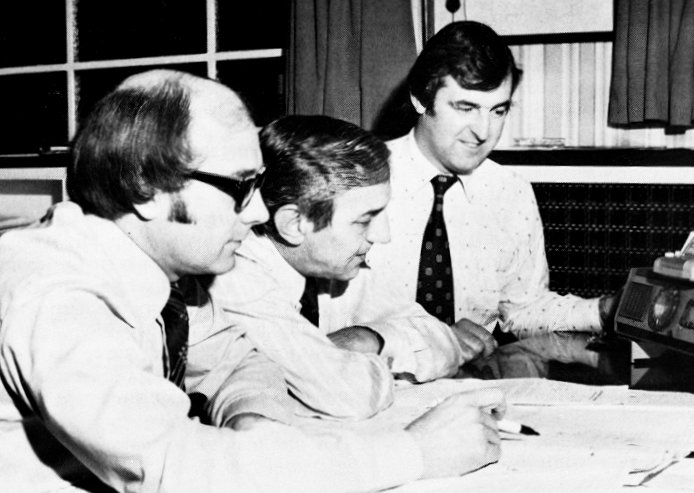

| In 1976 Mr. D. C. Lloyd

became Sales Manager at F. H. Lloyd & Company

Limited. His responsibilities included developing

the ever important export market.

From 'The Steel Casting',

courtesy of Wendy Marston. |

|

The team in the Sales

Office. Left to right: Terry Gaden, Keith Lort.

and Dan Lloyd. From 'The Steel Casting',

courtesy of Wendy Marston. |

|

In 1977 a

reorganisation scheme began at James Bridge

to create larger production areas, improve

the overall efficiency of the plant, and

provide better working conditions.

Improvements were made to the Sand

Preparation Plants, and a new sand slinger

rollover circuit was introduced in the Heavy

Foundry.

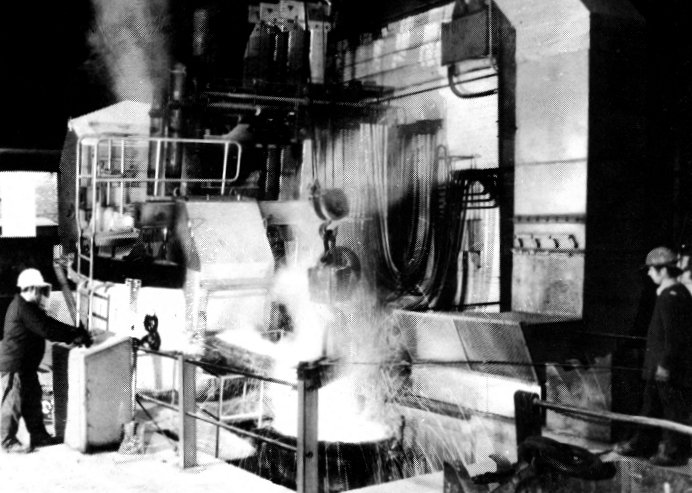

A new melting plant

with a £250,000 electric furnace was

installed, and the Pattern Shop was moved to

Keay's old building in Station Street. In

order to ease the movement of patterns from

the new stores to the main foundry area, the

old railway line which ran under the Walsall

Road was converted into a private roadway.

The old Pattern Shop became an additional

fettling area providing an additional 24,000

sq. ft. to the existing facility. Similarly

the Scrap Stores was moved from the Heavy

Foundry Bay to increase the working area. |

|

The new melting

plant. From 'The Steel Casting',

courtesy of Wendy Marston. |

The company's stand at

the Offshore International Exhibition.

Lloyds hoped to increase the number of

ever-important orders for castings from the

offshore oil industry. From 'The Steel

Casting', courtesy of Wendy Marston. |

The new Managing

Director of F. H. Lloyd & Company Limited,

appointed in 1977 was Allan Harris who had

joined the company as an apprentice in 1953.

From 'The Steel Casting', courtesy of Wendy

Marston. |

|

The pattern shop. |

F. H. Lloyd & Company had the largest steel foundry

business in Europe, but it fell into a severe decline in

the 1980s, which resulted in the closure of the

Wednesbury foundry in 1982.The Parker Foundry Limited

at Derby survived until 1987 leaving Lloyds (Burton)

Limited as the sole survivor.

|

| Shortly before the closure of

The Parker Foundry Limited, F. H. Lloyd was acquired

by Triplex plc to form Triplex Lloyd plc.

Although Lloyds (Burton) Limited was trading

profitably, it became irrelevant to Triplex Lloyd

which had other plans for the future. It was sold in

1989 to William Cook plc. At the time it was the

second largest producer of steel castings in the

country. |

Using the hydroblast system to clean steel

castings. |

| F. H. Lloyd Holdings Limited became part of United

Engineering Steels Limited, and the James Bridge site

became F. H. Lloyd Engineering Steels Limited, producing

a range of cast and rolled billets for other companies

in the group. In the 1989 Annual Report, the Directors

of United Engineering Steels Limited announced the

closure of the James Bridge site and the relocation of

its activities to the company's plants in South

Yorkshire. This must have come a terrible shock to the

loyal James Bridge workforce, who had worked hard and

achieved so much for the company. This was a sad loss

for the steel industry, particularly in the West

Midlands. |

|

A final view of the James

Bridge factory, seen from across the motorway.

Courtesy of Wendy Marston. |

|

|

|

|

|

Return to

the 1960s |

|

Return to

the contents |

|

Proceed to

personalities |

|