|

Iron and

Steel

In the 19th century, Walsall had several

ironworks, which must have been a spectacular sight.

Birchills Furnace

|

|

The earliest known blast furnace in the

town, which opened in 1803 was built in Birchills, and known

as ‘Old Birchills’.

It is listed in Thomas Pearce’s

History and Directory of Walsall, published in 1813. At the

time it was owned by Stubbs & James, and stood just to the

north of Reedswood Park.

The business is listed in David

Mushet's 'Papers of Iron & Steel, Practical and

Experimental' published in 1840 which states that in 1839 the

company was run by E. Tyler.

There was one blast furnace in

use, with a hot blast, producing around 45 tons of iron per

week.

The total production in 1839 was 2,340 tons. In 1872

the factory was run by J. Bissell and Son.

There were 16 puddling furnaces and 3 mills and forges.

|

An advert from1873. |

An advert from 1873.

|

An advert from 1873. |

It continued in use until the mid

1870s, by which time two new furnaces had been built near to

the Wyrley & Essington Canal.

The first, known as ‘New Birchills’ opened around 1840, and was built on the northern

side of the canal close to Green Lane, near to where the

TK-Maxx warehouse is today.

The owner, George Jones, who

lived in Shackerley, Donington, Shropshire, had several

nearby coalmines, Birchills Field, Harden, and Forest.

The

factory became known as Birchills Hall Ironworks, and later

as Staffordshire Ironworks.

By the early 1850s there were

five furnaces, and around 400 employees, producing around

20,000 tons of pig iron a year.

|

|

An advert from 1896. |

|

An advert from1899. |

In the mid 1850s George

Jones’ son John took over the business, which he ran until

1867, when it was sold.

At the time there were 28 puddling

furnaces, a foundry, and rolling mills.

It was taken over by

J. Brayford, who had died by 1872. He had 4 blast furnaces,

and operated 12 puddling furnaces, and 2 mills and forges.

The factory was soon divided into two

separate concerns.

In 1872 the rolling mills and finishing

plant were sold to two companies, Bunch, Jones & Company

(later Benjamin Bunch & Sons),

and the Birchills Hall Iron Company Limited.

The blast-furnaces were

acquired by the Birchills Estate Company, which sold them to

the Castle Coal & Iron Company in the late 1870s.

|

| The location of Birchills Hall

Iron Works. |

|

| Another ironworks stood on the

opposite side of Green Lane, between the road and the canal,

just north of Birchills Junction where a landscaped open

space is today. It was built in 1851, and owned by Frederick

Parkes. The factory had two furnaces and became known as

Green Lane Furnaces. In the 1860s it was acquired by the

Walsall Iron Company, owned John Jones & Sons, and in 1894

was sold to John Russell & Company, wrought-iron and tube

manufacturers.

Around 1907 the factory was taken over by Birchills Furnaces Limited, and continued in operation until

around the end of the First World War. It closed in the mid

1920s and was demolished in the late 1930s.

There were two terrible accidents at ironworks in

Birchills. The first took place on 15th October, 1875 at

Birchills Iron Works, where a blast furnace exploded as

it was being tapped. The explosion was caused by a burst

tuyère, which resulted in furnace workers being covered

with molten metal and red hot ashes. Three men died

instantly, and twelve others, all with serious burns

were rushed to the Cottage Hospital.

Sister Dora immediately took charge

of the men and treated them alone, shutting herself up

in their side ward, nursing them both day and night for

several weeks. Despite all of her efforts, ten of them

died from their terrible injuries.

The second explosion occurred on

the 15th of May, 1880, when a Rastrick boiler exploded

at Birchills Ironworks. Twenty five people were killed,

and thirty injured, many of whom had very serious

injuries. |

| |

|

|

|

|

Read about the explosion

at

Birchills Hall Iron Works in 1880 |

|

|

Read about the explosion

at

Birchills Iron

Works in 1875 |

|

| |

|

|

|

|

|

Pelsall Ironworks

Another large ironworks was built at

Pelsall on the northern side of the Wyley & Essington Canal, to the east of the Cannock

Extension.

Pelsall Ironworks opened in 1832 and was built by Mr.

Richard Fryer, a Wolverhampton banker who became one of the

first two members of parliament for Wolverhampton, and

owned, and lived at the Wergs Estate.

|

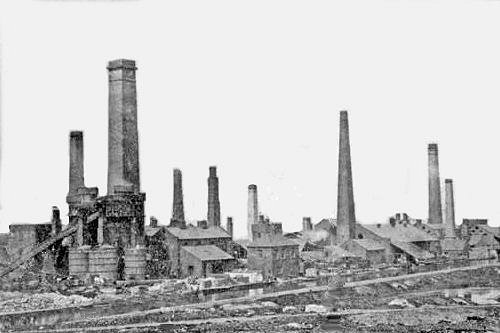

Pelsall Ironworks. |

| After his death in 1846 the ironworks was sold to Davis

and Bloomer. It is listed in William White’s 1851 History,

Gazetteer, and Directory of Staffordshire as producing bar

and sheet iron of the best quality. After Mr. Davis’s

retirement, the firm was run by Boaz Bloomer and his son who owned

several nearby coal mines, which supplied the ironworks.

They changed the name of the business to The Pelsall Coal and Iron Company.

It grew into an extensive ironworks with two blast

furnaces, forty puddling furnaces, seven mills and forges, a

gashouse and gasometer, and an large tramway with locomotive

and wagon sheds.

Several hundred people worked on

the site, and iron was exported to many countries throughout

the world including America, India, and China. Success

continued until the recession in the iron trade in the

latter quarter of the 19th century. In 1891 the firm lost

£3,647.11s.7d. The company was forced into liquidation in

1892 when repayment was demanded for an overdraft of

£20,000.

The coal mines were sold to the Walsall

Wood Colliery Company, and the plant was sold-off cheaply to

Alfred Hickman of Bilston Steelworks. It was a sad end to

such an important local employer. Its demise led to a crisis

in the village because of the large number of inhabitants

who lost their jobs. Many of whom had previously moved to

Pelsall after finding employment at the works. The Bloomer

family were strong Methodists and benefactors. They were

greatly involved in the building of the Methodist Chapel in

1858, and the Wesleyan day school in 1866. In the 1860s Boaz

Bloomer opened a room at the works where daily newspapers

and periodicals were available for employees to read.

The ironworks had a Tommy shop in Wood

Lane near the canal bridge, where the employees could

exchange the tokens (that were given as part of their wages)

for all kinds of goods. After the closure of the firm, the

Bloomers moved away from the area, but left a lasting impression on the

local community. The chimney stacks, the last remaining part

of the factory, were demolished in the 1920s.

Hatherton Furnaces

In 1845 Richard Fryer who founded

Pelsall Ironworks leased a piece of land from Lord Hatherton

on which to build an ironworks, and mine coal. The land was

on the northern side of Leamore Lane, alongside the canal.

When Richard died in 1846 his son William took over the

lease. The factory, which became known as Hatherton

Furnaces, had two furnaces. Around 1870 it was leased to

George and Richard Thomas of Bloxwich, whose company became

G. & R. Thomas Limited. Richard Thomas died in 1920, and the

firm survived until 1935, when it went into liquidation. Its

assets were sold, and the furnaces continued in use until

1948. The site was later used as a foundry.

Ironworks at Pleck

In the latter half of the 19th century, Pleck became an important manufacturing centre when many

heavy industries grew-up alongside the canal. It began in

1851 with the opening of Sinkinson & Lancaster in Pleck

Road. The firm produced bar and sheet iron, and rolled

sections. Within a few years it was taken over by Brayford &

Lancaster. |

|

An advert from 1953. |

The largest ironworks in the area was

Edward Russell's Cyclops Ironworks in Pleck Road which had

22 puddling furnaces and 3 rolling-mills.

The firm produced

iron and steel tubes of all kinds. |

| |

|

|

|

|

Read about John

Russell &

Company |

|

|

Read about tube making |

|

| |

|

|

|

|

|

Another large factory on Pleck Road was

the Staffordshire Galvanising and Iron Company which was in

operation by 1875. The business was extremely successful and

took over the adjacent Victoria Ironworks in about 1890.

In

the late 1870s it became Walker Brothers, which in turn

became part of the Benford Fabrications Group. Products

included galvanising and sheet metal work, wire netting,

sheep troughs, and iron roofs. Some of the products were

exported to the Far East and South Africa. After the second

World War galvanised sheet production ended and the company

concentrated on galvanised steelwork.

Other factories in Pleck Road included

Walsall Tube Works, Crescent Chain Works, James Iron

Foundry, the Bridge and Roofing Works, and Junction Saw

Mills. On the other side of the canal was Bradford Tube

Works, Bradford Iron Works, and Globe Iron Works. |

| Another manufacturer based in Pleck Road was Hope

Works Limited. The firm, which moved to Pleck Road from

Selbourne Street, had been acquired by Walsall iron

merchants Thomas Franks and Sons Limited, in

Wolverhampton Street. One of Thomas Franks' sons

Alfred, became Chairman of Hope Works Limited, which

subsequently opened a branch in Bloxwich.

The firm eventually became part of Laidlow & Thomson

Limited, 60 Cannon Street, Manchester.

The image on the right is from the cover of the

company's catalogue produced in the early 1940s. It

contains all kinds of ornamental ironwork which were

coated with "Corresista", a rust preventing zinc paint,

and treated with Hopsall stove synthetic finish. At

extra cost, all the company's products could be

Sherardized, and were also available in solid brass,

finished in an old-looking colour.

A few of the many products from the catalogue can be

seen below: |

|

Door and window fittings.

Letterboxes with handles and knockers.

Door or gate handles.

Hinges.

Nameplates, grills, and hanging lamp.

|

An advert from 1976. |

Until recently, a once well-known

factory

stood at the western end of Pleck beside the canal, on the

site of the former James Bridge Brick Works. This was the

James Bridge Copper Works which opened in 1919 as a

subsidiary of the Wolverhampton Metal Company Limited.

In

1931 the factory was forced to close by Walsall Town Council

after a series of complaints about the sulphurous fumes that

came from the 100ft. high chimney. At the time around 150 manual

workers who worked in the factory lost their jobs. Taller

chimneys were built, and the factory reopened the following

year.

It was forced to close again

in World War 2 because of blackout problems, but reopened

after the war to recover copper from war surplus items.

The

firm became a Limited company in 1946, and in the early 1950s

became one of the country’s leading copper reclamation

companies. All kinds of waste materials including ash and

foundry residues were transported to the factory to produce

high quality copper. |

| In 1967 the plant was updated to increase production of

high grade electrolytic copper from 15,000 to 50,000 tons a

year. During the same year James Bridge Copper Works Limited

became part of IMI Limited (Imperial Metal Industries

Limited) and became known as IMI Refiners Limited. It was

the last copper refining business in the country, but sadly

closed on 31st December, 1999. The factory was demolished in

2000. |

|

Other tube manufacturers

In the 19th century Walsall became an

important centre for the production of the wrought iron

tubes that were essential for the supply of town gas. The

industry began in Walsall with the formation of Edward and

William Dixon’s firm in 1829. The company started making gas

tubes in Birmingham Street in 1830, and around four years

later moved to the Alpha Tube Works on the western side of Ablewell Street.

By 1868 the firm changed its name to

Lambert Brothers, and in the early 20th century moved to new

premises beside the canal in Green Lane, also called Alpha

Tube Works. Along with wrought iron and mild steel gas

tubes, the company produced gas valves, lamp columns and

manhole covers.

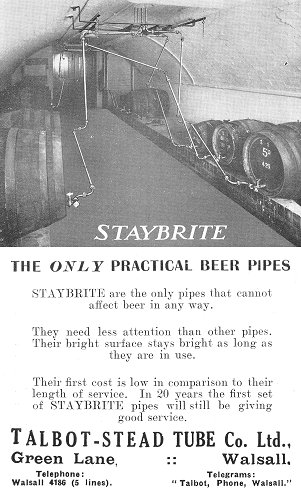

The largest tube manufacturer in the

town was the Talbot-Stead Tube Company Limited, founded in

1906 by W. J. Talbot and Geoffrey Stead. They opened a

factory in Green Lane for the production of seamless steel

tubes. In the First World War the company supplied around a

quarter of the boiler tubes used by the Royal Navy.

In 1931 the firm became part of Tube

Investments Limited, and in 1962 became T.I. Stainless Tubes

Limited. The factory closed in 1972, and in 1973 was

acquired by T.I. Chesterfield Limited. |

An advert from 1935.

|

|

An advert from 1896 for Hildick &

Hildick, Walsall Tube Works, Pleck Road. |

An advert from 1851.

| Other non-ferrous metal producers |

|

McKechnie Metals Limited

In 1871 Duncan McKechnie established a

factory at

St. Helens, Lancashire, for copper extraction,

where he produced refined copper ingots, bar silver, pig

lead and copper sulphate. In 1894 the firm became an early

pioneer in the brass and copper alloys extrusion business,

after opening a factory in Birmingham.

Over the years the demand for the

company's products grew, which led to the construction

of a new factory in Middlemore Lane, Aldridge in 1954. The

factory was equipped with the most up-to-date equipment, and

soon all of the company’s production was moved there. The

firm specialised in the production of alloys to individual

customer’s specifications, and the extrusion some of the

more unusual materials. Products also included large numbers

of brass ingots, particularly in die-casting qualities, and

billets to all

specifications.

Branches of the company were

established in South Africa and New Zealand. |

An advert from 1976. |

|

The firm became known as known as McKechnie Brass Limited and produced a wide range of alloys

for many diverse applications. Brass products include

billets, round rod, shaped rod, turned parts and stampings

for the water, gas and electrical industries. Other products

included, locks, handles, lift tracks, showers, electrical

fittings, and copper trolley wire, which was used to supply

electric power to high-speed trains, locomotives and trolley

buses. Sadly the firm went out of business in 2013, having

accrued debts of £3.8 million. Sixty people lost their jobs.

In 1902 another non-ferrous metal

manufacturer, New Delaville Spelter Company Limited opened

the Delaville Spelter Works in Willenhall Lane, Bloxwich. By

1918 the company had eight furnaces on the site for smelting

zinc ash, and two others for recovering zinc from hard spelter.

Products included zinc oxide, and zinc dust. In 1933 the

firm was taken over by the Imperial Smelting Corporation.

After the Second World War production was limited to zinc

dust, Mazak zinc alloy for die-casting, and high purity zinc anodes. |

An advert from 1896. Walker Brothers were

based in Pleck Road.

An advert from 1958.

|

Return to

the

previous page |

|