| Although Wednesbury is well known for the production of

tube and tube-fittings, it also had several manufacturers

who specialised in the production of cast iron gas, steam,

and water main cocks. One of the earliest, and the longest

surviving producer was Richard Garbett, based at Monway Gas,

Water, and Steam Cock Manufactory, 64 Portway Road,

Wednesbury. |

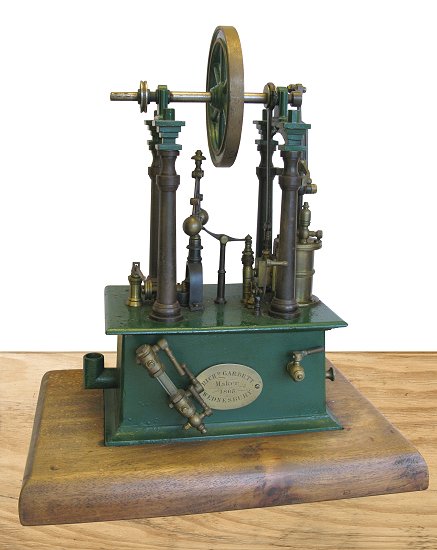

| Richard Garbett and his

descendants were, and still are, extremely skilled

engineers. Richard's skill

and fine workmanship can be appreciated by looking at the working model of a

steam engine, opposite, that was built by him in 1865.

|

|

The location of Richard Garbett's

factory, at the northern end of Portway Road, by its

junction with Holyhead Road. |

Unfortunately little is known about the company, which

was founded by Richard Garbett in 1872. The business

remained in family hands until the end. When Richard Garbett

retired, his nephew John Thomas Garbett took over, followed

in turn by his three sons, Frank, Harry, and Sidney.

They were ably assisted by other family members including

Doug Garbett, Leonard Garbett, Jackie Garbett, and Alf

Arnold.

Thanks to the family's hard work, the business survived

for over one hundred years, producing a wide range of cast

iron gas, water, and steam cocks of all sizes. It closed in

the early 1980s. |

| It must have been a happy place to work. The employees

were very loyal, most of them staying there for much of

their working lives. |

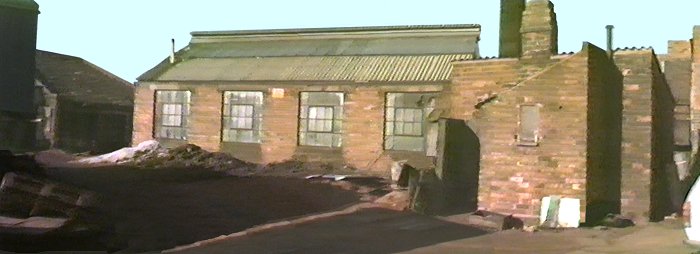

An impression of how the factory looked, as

seen from the eastern side of Portway Road.

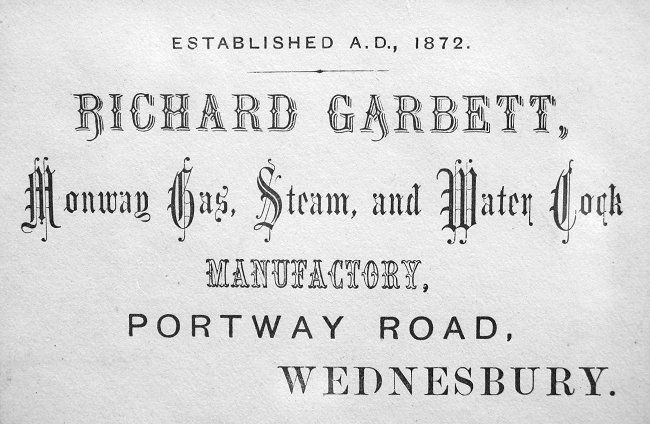

An old business card.

An advert from 1918.

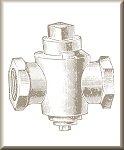

A range of Garbett's iron main cocks with

brass plugs.

|

A small cast iron main cock. |

|

A much larger version. |

|

The front of the factory. Courtesy of Ian S.

Bolton.

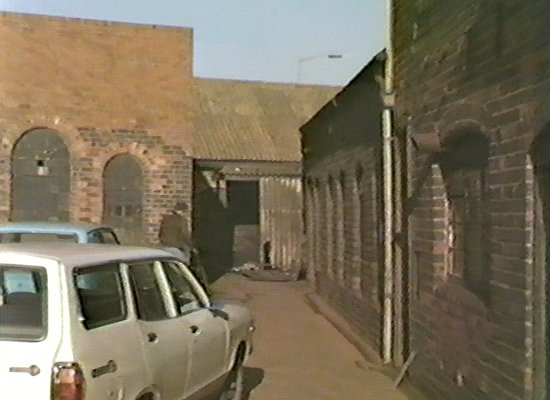

| The following photographs are stills from a video film made

on an early camcorder, by Tony and Pauline Highfield, just

after the factory closed. |

The factory yard showing the back

of the main building with the office upstairs, and the

gateway into Portway Road. |

|

Another view from the yard looking

along the back wall of the main building. |

The buildings at the northern end of the yard,

with the furnace in the background.

|

The cupola furnace that produced the

iron for the foundry. There

was also a brass foundry which produced the castings for the

plugs that were used in the cocks. |

|

|

A close-up view of the bottom of

the furnace. |

| The building in the western corner

of the yard that was originally a stables. |

|

|

The machinery in the factory was

driven by overhead line shafting. In this photograph Doug

Garbett sorts out a belt that has come off the pulley.

|

| One of the grindstones in the sand

mill, which prepared the sand for the foundry. |

|

|

The hydraulic testing machine that

pressure-tested the completed cocks. |

| A batch of finished cast iron main

cocks in the warehouse. |

|

|

A view of some of the cast iron

cocks that were on the shelves in the warehouse. |

| Another view of finished products

in the warehouse. |

|

|

A large cast iron main cock with a

brass plug. |

| Another view of the cast iron main

cock. |

|

|

A slightly smaller cast iron main

cock. |

The top of a receipt from the 1890s.

After closure, much of the machinery was generously

donated to the Black Country Living Museum. If anyone has

any information about the firm, please

send me an email. I

will be delighted to hear from you.

I would like to thank Tony and Pauline Highfield, and

Richard W. Garbett for their help in producing this section. |

|

Return to

the

previous page |

|