|

The Patent Shaft & Axletree Company - The Early Years

In the early 19th

century, coach axles were made by welding together a

bundle of wrought iron strips. Such axles would often

fail because some of the strips were not as strong as

others. The Patent Shaft took its name from an improved

axle which overcame the problem, and was founded by the

inventor to manufacture the new axle.

Around 1830,

James Hardy, a minister at the Independent Chapel in Holyhead Road, and an enthusiast about anything

mechanical, developed the new axle. According to F. W.

Hackwood in his “Wednesbury Workshops” Hardy got the

idea from the cross section of an orange when cut in two

horizontally. The new axle consisted of a central bar

surrounded by smaller bars to form a circle. The outer

bars were round instead of flat to avoid cross graining

the iron, when they were heated and welded under the

hammer. This produced an axle of equal strength

throughout its whole length.

|

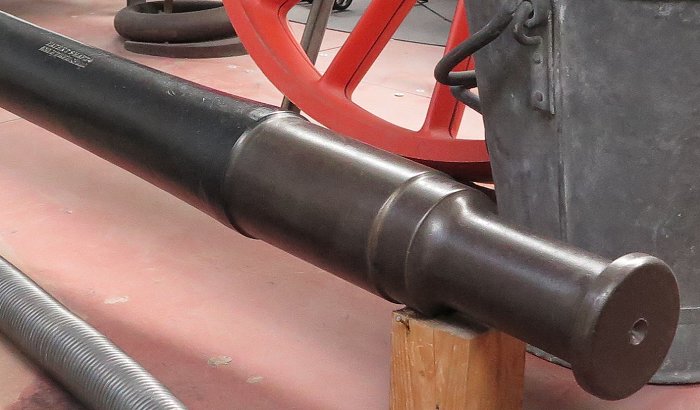

The Patent Shaft axle that is

on display in Hall 1, in the Rolfe Street Baths

building, at the Black Country Living Museum, in

Dudley. It is opened-out to show the bars that were

welded together to form the axle. |

|

The other end of the axle in

the previous photo, which has been machined into its

final form. |

|

The maker's name stamped into

the axle above. |

|

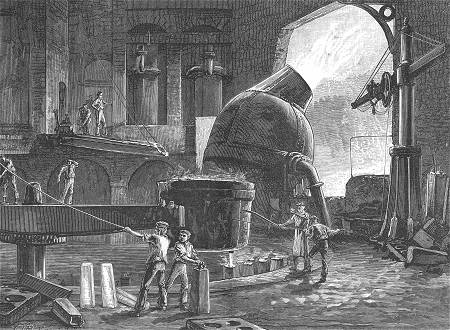

A Bessemer Converter. |

Hardy decided to patent the idea,

and with financial help from Samual Hodgetts, a grocer

from Toll End, he took out a patent in 1834. Hardy and

Hodgetts decided to set themselves up in business to

produce the new axles.

They purchased a forge at Leabrook

for £1200 from Joseph Rollason. At the forge were 2

puddling furnaces, a scrap furnace, and an engine. |

| Although work was undertaken to

improve the facilities on the site, no axles had been

produced by 1836. As a result Hodgetts became

disappointed with the project and withdrew.

Hardy soon found four other partners and began to devote

his whole life to the project, but production still

didn’t get underway and the business got into more and

more debt with the Birmingham and Midland Bank. The

bank’s manager Charles Geach realised that the axles

would be ideal for use on the rapidly growing railway

network, and that large numbers of reliable axles would

be required. Geach didn’t waste any time, and along with

12 men, including Hardy, he purchased the works and the

patent, and formed the Patent Shaft & Axletree Company

in 1838. |

|

An advert from 1870. |

| Within 2 years Hardy left and took Anglican orders.

He was replaced as manager by his ex-clerk Thomas

Walker. In 1844 thanks to Walker’s efforts, the London

& North Western Railway adopted the patent axle, and the

company’s future was secured. In 1852 the company

purchased the adjoining Victoria Iron Works from

Fletcher, Rose & Company. |

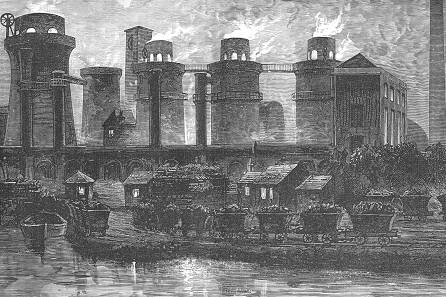

Blast furnaces at night.

|

| Geach died in 1854 and the company was purchased by

Thomas walker. At the time they had a railway steel

works, 5 forges, 4 mills, 12 hammers, more than 100

puddling furnaces, and employed over 800 men.

In 1864 the business became a limited company with a

capital of £300,000. Thomas Walker became Chairman, and

his assistant manager Richard Williams became General

Manager. The works now covered over 12 acres and

employed 1,500 men working around the clock. They

produced large numbers of products including axles,

wheels, tyres, rails and boiler plate.

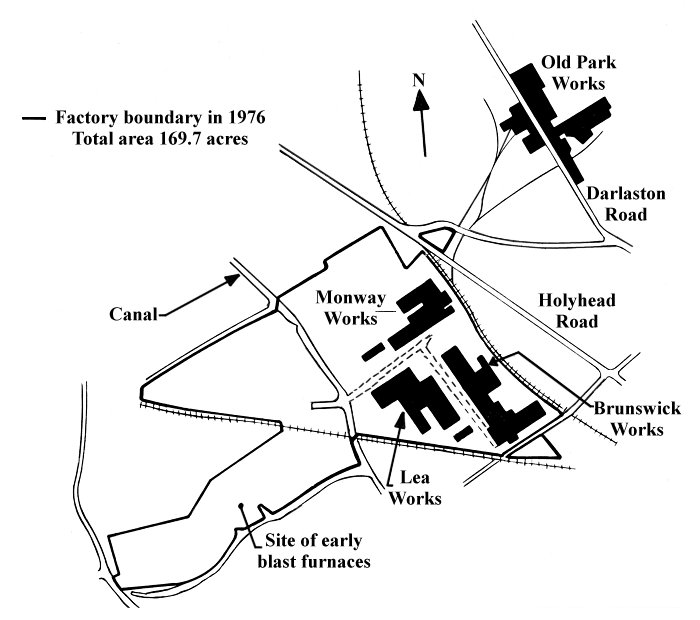

In December 1866 the Patent Shaft

purchased the loss-making Monway Works and Old Park Works from

Joseph Foster Lloyd & Company after

their disastrous Blackfriars Bridge project.

The works and collieries were bought for £400,000. The

company could now produce wrought iron, Bessemer steel,

and constructional ironwork, all made from their own raw

materials.

At the time the company had 86

puddling furnaces, 3 blast furnaces and became one of

the most prosperous factories in the country.

|

|

|

|

Return to the

beginning |

|

Proceed to

Old Park Works |

|