|

Old Park Works

In 1818 Lloyds,

Fosters & Company opened a coal mine near Hob’s Hole.

They were heirs of Richard Parkes, who in 1708 had

acquired a lease on the coal mines in the area. The coal

mine, like many others in the area suffered from

flooding, and so Samuel Lloyd installed a steam engine

to pump out the water. The site also contained large

quantities of iron ore, and also clay, which was used to

produce bricks and tiles.

The company

built an iron works and a foundry on the site, so that

the iron ore could be used to produce pig iron and

malleable iron for the foundry. All kinds of items were

cast including ironwork for buildings and bridges, parts

for steam engines, and wheels and axles for the

railways. Even complete locomotives were built. In 1849,

Old Park Works became the first factory in Staffordshire

to use the hot blast in their furnaces, which produced

high quality iron for the foundry.

|

|

An advert from 1851. |

|

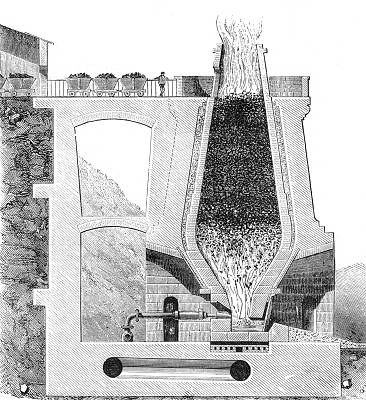

A cross section through a 19th

century blast furnace. |

Blast furnaces

originally used a cold blast, from air at normal

temperature. The cold blast cooled the furnace and so

large amounts of fuel were required to maintain the

temperature.

In the hot blast furnace the air was

pre-heated using the waste gases from the furnace which

greatly reduced the cooling effect and saved the company

around 10,000 tons of coal a year.

In 1854 the

company opened The Monway Axle and Tyre Works at Monway

Field. The new works produced axles, tyres, and iron

plate for boilers and bridges. |

| Samuel Lloyd was known as "Quaker

Lloyd" because of his religious beliefs. He was a good

employer whose kindness could be seen from the help that

he gave to widows and orphans of employees who lost

their lives in the company's collieries. He also built a

school where the orphans could be educated.

The company had a large truck shop

that sold only the best quality goods. Prices were low,

often lower than in the town centre shops. Samuel Lloyd

took great pride in buying the chief articles himself,

particularly tea, bullocks and sheep. The shop sold the

best butcher's meat in the town. Samuel Lloyd

died in 1862. Just before his death he signed an

agreement with Henry Bessemer for the use of the

Bessemer process, which the company began to use in

1865.

This was the first factory in the

Black Country to make mild steel, at a time when Old

Park Works were the largest steel works in the area,

employing over 3,000 people by 1866. There were 3 blast

furnaces, large machine shops, and foundries.

|

|

The company obtained a large order to supply the

ironwork for Blackfriars Bridge in London. Unfortunately

the building contractor was unable to pay for the

ironwork. As a large sum of money was at stake, Lloyds

and Fosters decided to finance the contractor until the

bridge could be completed. This soon led to the

company’s downfall because of unforeseen circumstances.

When work started on the bridge piers it took a long

time to find a suitable solid foundation, which greatly

increased the overall cost. As a result the company lost

£250,000 and in 1867 Old Park Works and Monway Works had to be sold to cover

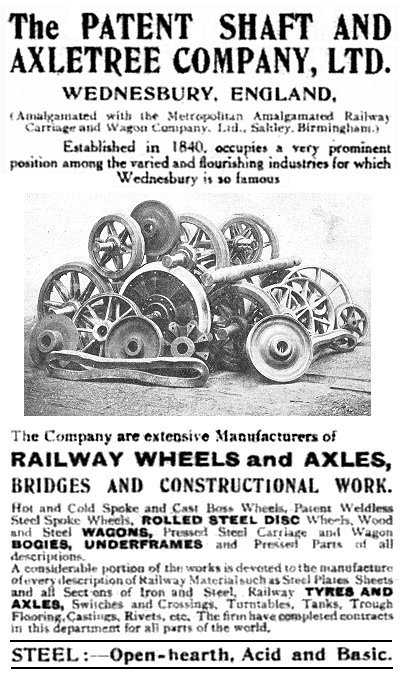

the loss. The company was purchased by The Patent Shaft

& Axletree Company and became part of the largest steel

works in the area. |

Henry Bessemer.

|

|

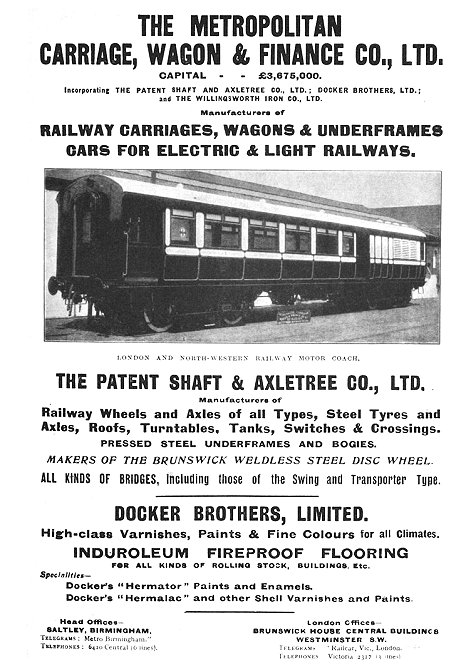

On the 18th April, 1902 the Patent

Shaft

& Axletree Company became part of the Metropolitan

Amalgamated Railway Carriage and Wagon Company Limited,

which was formed with a share capital of £1.5m to take

over the business of the Metropolitan Company and to

amalgamate with the following companies:

The Ashbury Railway Carriage and

Iron Company Limited, Brown and Marshall's Company

Limited, The Lancaster Railway Carriage and Wagon

Company Limited, The Willingsworth Iron Company Limited

and The Oldbury Railway Carriage and Wagon Company

Limited.

In 1912, Dudley Docker, the

company's Chairman, proposed changing the name of the

company from the Metropolitan Amalgamated Railway

Carriage and Wagon Company Limited to the Metropolitan

Carriage, Wagon and Finance Company Limited.

|

An advert from 1919.

|

Old Park Works from Old Park Road.

|

| During the First World War, the company concentrated

on war work, and as a result made record profits. Some

of the first tanks were built at Old Park Works, which

at the time had between 1,300 and 1,500 employees. At

the end of the war, part of Old Park Works was used by

Vickers Limited of Sheffield, who in 1919 purchased the

Metropolitan Company. In 1929 Vickers Limited and

Cammell Laird & Company of Birkenhead, amalgamated their

steel making and carriage building businesses. This

resulted in the formation of the Metropolitan Cammell

Railway Carriage and Wagon Company. The take over had

one immediate effect at Wednesbury, the separation of

Old Park Works and the Patent Shaft. Vickers, who had

already been using part of Old Park Works took over the

remainder.

In 1938, war work began with a batch of forty five

A10 cruiser tanks. By 1942 Metropolitan Cammell was

producing 82 Valentine tanks a month, with production

equally divided between Old Park Works and the firm's

Midland Works. Over three and a half years, the firm

built 2,135 Valentines. During the war, 435 Churchill

tanks were built at Old Park Works, along with 75

Cromwell tanks, fitted with a 77mm high velocity gun.

Other war work included the production of armoured cars, artillery trailers, pre-fabricated hulls

for tugs and light tankers, and a small quantity of

railway rolling stock.

After the war, a train for the Royal Tour of South

Africa was built at Old Park Works.

In 1949 Old Park Works were sold outright to

Metropolitan Cammell to become part of the

Metropolitan Cammell Railway Carriage and Wagon Company

Limited, which also had factories at Elmdon, Saltley, and

Washwood Heath. |

|

A wagon plate from 1947. |

The works now concentrated on the production of

railway coach bodies, railway wagons, and pressings of

all kinds for the other factories in the group. Old Park

Works also produced electric locomotives, and so a 65ft.

turntable and a test track was installed for the

purpose. In 1960 a total of 35 locomotives were sold to

South Africa.

In 1964 Old Park Works was acquired by the Owen

Organisation, but sadly closed as a result of the

recession in the 1970s and 1980s. |

|

|

|

|

|

Return to The

Early Years |

|

Return to the

beginning |

|

Proceed to

Take Over |

|