| The Patent Shaft

Steel Works Limited - The Factory in the Late 1970s |

|

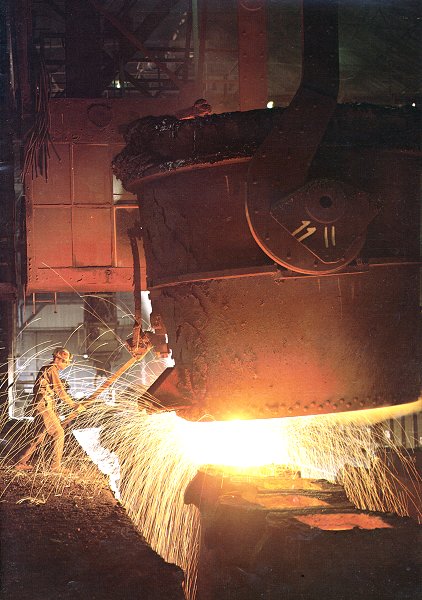

One of two Birlec UHP

electric arc furnaces, 5.8 metres in diameter, rated

at 45 MVA, with a nominal capacity of 88.5 tons.

They were charged with scrap

from baskets that had been loaded in the scrap

handling bay.

Each furnace had its own

load cell weighbridge with a VDU that indicated the

weight and grades of scrap required.

Oxygen for the furnace was

supplied by an oxygen lancing rig.

The molten steel was tapped

into ladles, then teemed into ingot moulds for

transfer to the primary mill. |

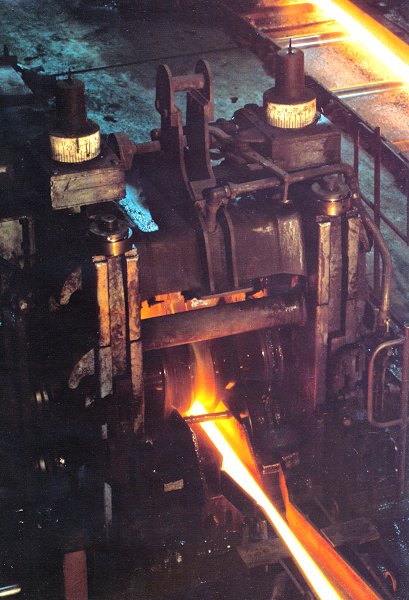

| Teeming molten steel from

the ladle into ingot moulds, before they were taken to

the primary mill, where ingots were stripped from

their moulds and heated to a rolling temperature of

around 1,250 degrees centigrade.

They were then rolled to

produce slabs or billets, which were cut to

pre-determined lengths. |

|

|

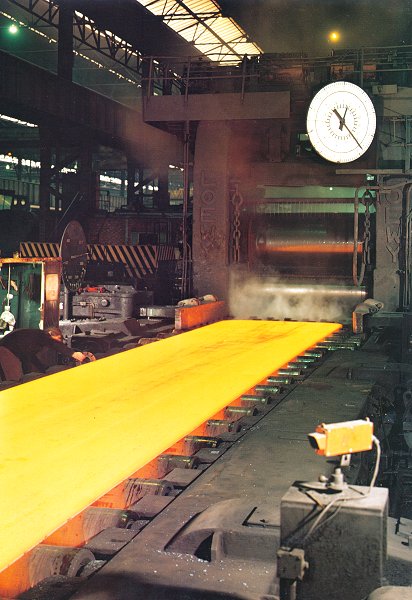

The primary rolling mill. |

|

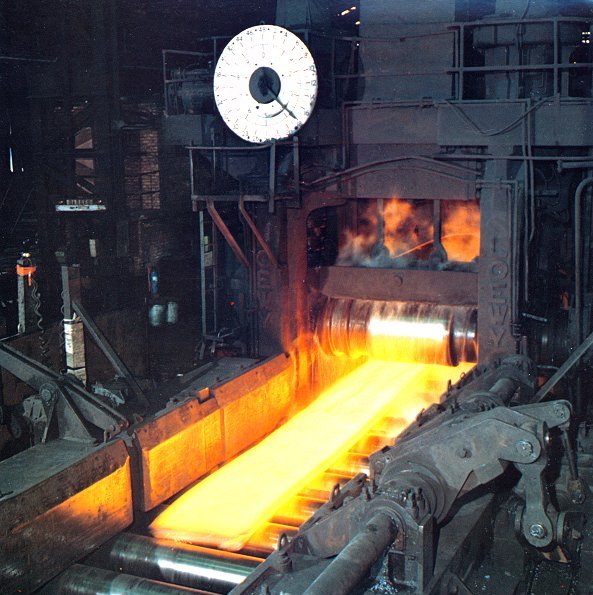

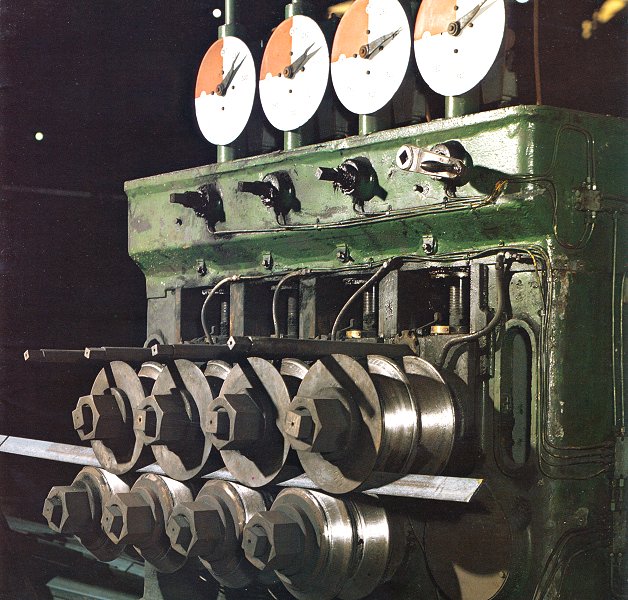

The plate mill

where slabs were initially heated to around 1,200

degrees centigrade in a push-down or a rotary hearth

furnace, in readiness for rolling.

After descaling, the slabs were

rolled on a 4 inch high, reversing mill. The plate

was rolled on heavy back up rolls to ensure that the

gauge was even over the entire width of the plate.

After rolling, the plates

passed through an eleven roll hot leveller, then

along a plate cooling conveyor, to the marking bed. |

|

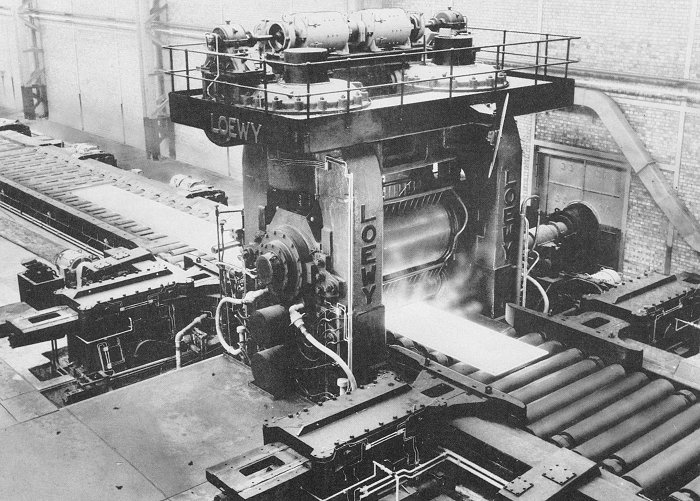

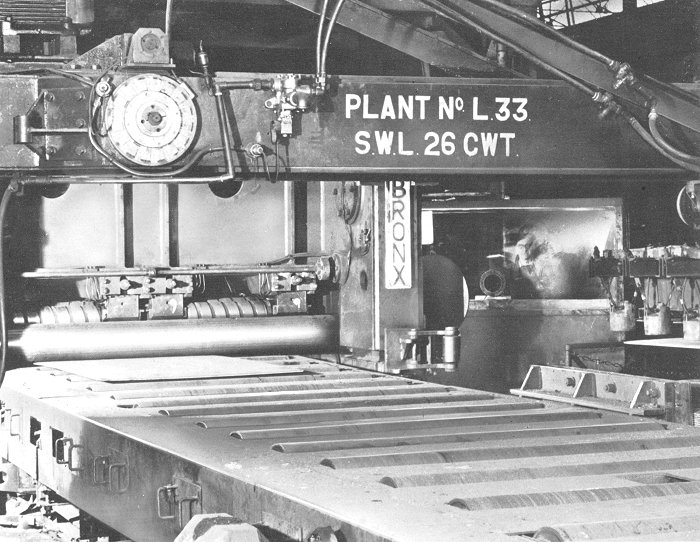

Another view of the

Loewy reversible rolling mill, in the plate

mill. |

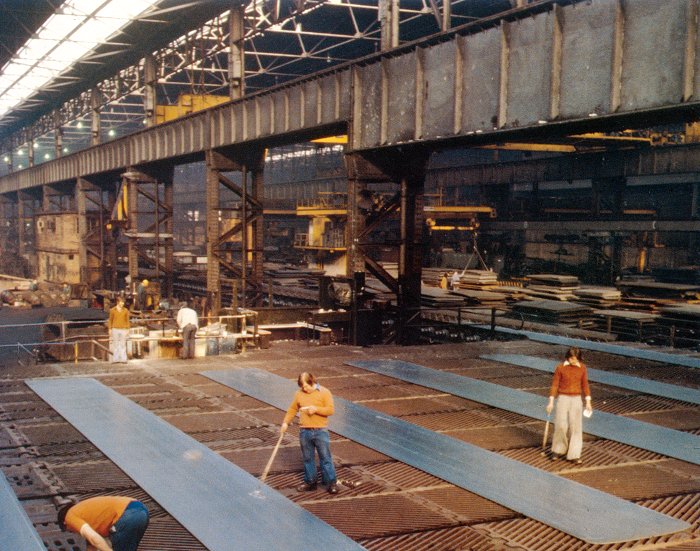

The plates were carefully

surface inspected before they were sheared, to

ensure a constant width, then cut to length by a

cross-cut shear. |

|

The plates were then

levelled in one of two levelling machines. |

|

The bar and section mill

where billets from the primary mill were cut to size

and brought-up to a rolling temperature in a

push-down reheating furnace, before transfer to the

rolling mill. |

In the rolling mill the

billets were rolled to a wide range of angles, flat,

or square bars. A high degree of straightness was

maintained. Additional finishing facilities included

cold sawing, heat treatment, shot blasting, pickling

and oiling, painting and bundling. |

Quality control of steel

plates began with the steel itself. Two Quantovac

emission spectograph analysers were used to

determine the exact specification of the steel.

Other tests included tensile, impact, and bend

tests. |

|

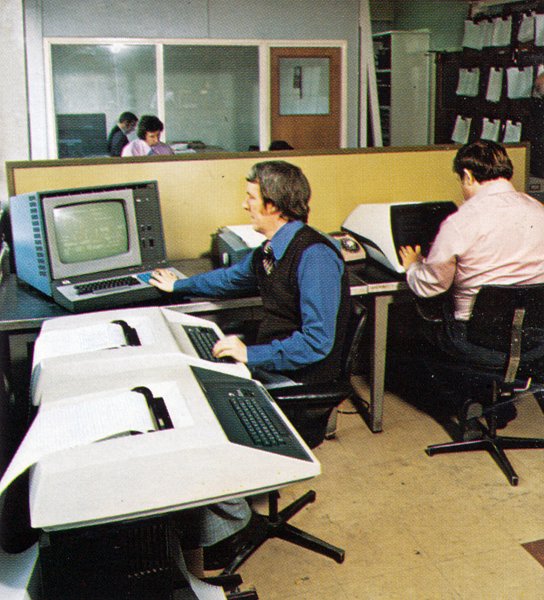

The sales and

production planning department ensured that the

correct product was delivered to the

correct place at the correct time.

Progress information was

continuously transferred to the planning office

where the planning was assisted by the ICL 1902A

computer. |

| The maintenance

section had a machine shop, a diesel repair

workshop, and central engineering stores. Staff

included engineers, bricklayers, erectors,

carpenters, and plate layers.

The computer system

provided a record of the sequence and magnitude

of plant faults. This allowed steps to be taken

to limit the effects of major plant

breakdowns. |

|

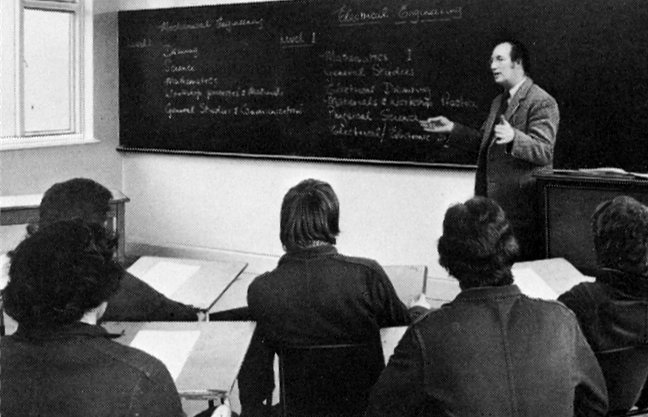

A training school was

established where full-time supervisors

taught a variety of specialised skills to

apprentices, who were encouraged to attend

courses in technical or commercial colleges

in order to obtain appropriate

qualifications. |

|

A workshop in the

training school. |

The fully equipped

surgery was available for the use of all

employees. The factory was also regularly

visited by a qualified medical officer.

There were Works Safety Committees, a Joint

Works Council, and a Staff Council where

representatives of the employees could

discuss a wide range topics with management.

There were also modern kitchen and canteen facilities

that supplied full meals or snacks to employees,

and the Shaft Social and Athletic Club

provided first class facilities for many

sporting activities including football,

fishing, snooker, badminton, and ladies'

netball. |

|

|

|

|

|

Return to

Development Schemes |

|

Return to the

beginning |

|

Proceed to

Closure |

|