| The Patent Shaft

Steel Works Limited - Development Schemes |

|

Throughout 1971 studies on the

development of the company, considered to be

essential for its future well being, were carried

out, and a report was prepared and submitted to The

Laird Group in May 1972. The recommendations were

based on developing the company at a minimum capital

cost, in order to provide moderate growth and to

enable further development at a later date, to meet

technological and commercial changes.

|

|

The report recommended that

steel plant production should be increased by

replacing two of the six open hearth furnaces with

one electric arc furnace, the plate mill finishing

facilities should be improved, as should the quality

of the section mill products by installing an

independently driven finishing stand and a walking

beam cooling bank.

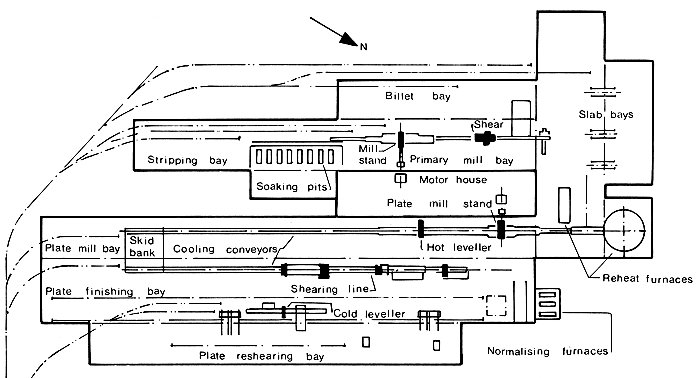

The Board decided that the

development work recommended should be carried out

in phases, commencing with improvements to the plate

mill which produced plate in thicknesses from 5mm to

80mm, and with a maximum plate width of 2,290 mm, and

a maximum plate weight of 39 tons.

A new mill complex consisting

of a slab yard, a reheating furnace, a rolling mill,

a plate shearing line, and handling facilities was

installed on the Lea Works site to process plate

production from 4,576 tons of slabs per week. Work

on the new plant was completed in December 1973.

|

An advert from the early 1960s. |

|

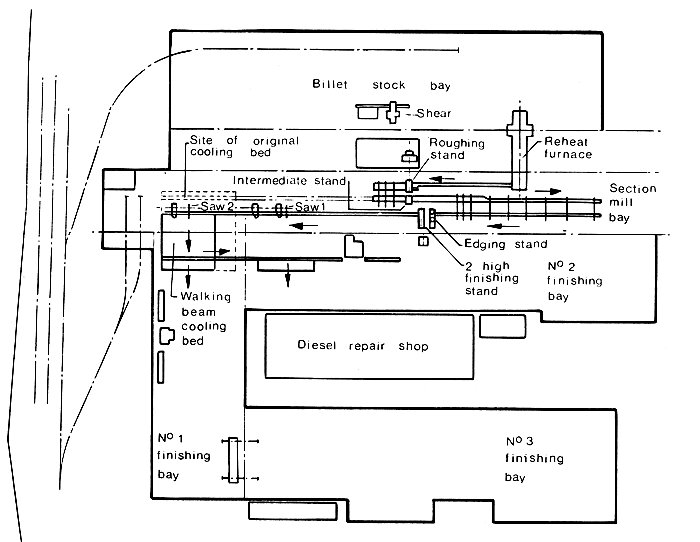

Layout of the primary and

plate mills at Lea Works. |

|

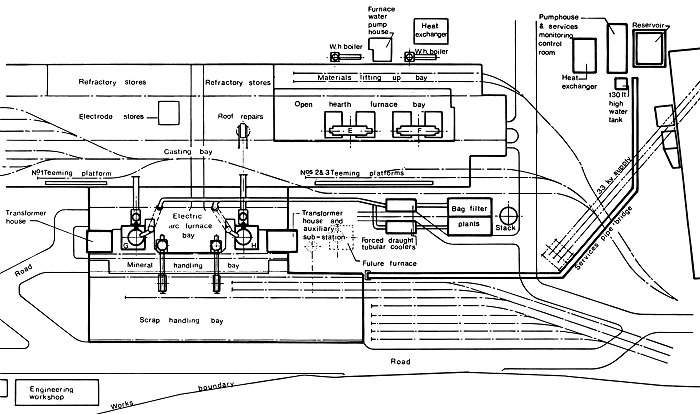

Layout of the new steel plant

at Brunswick Works. |

|

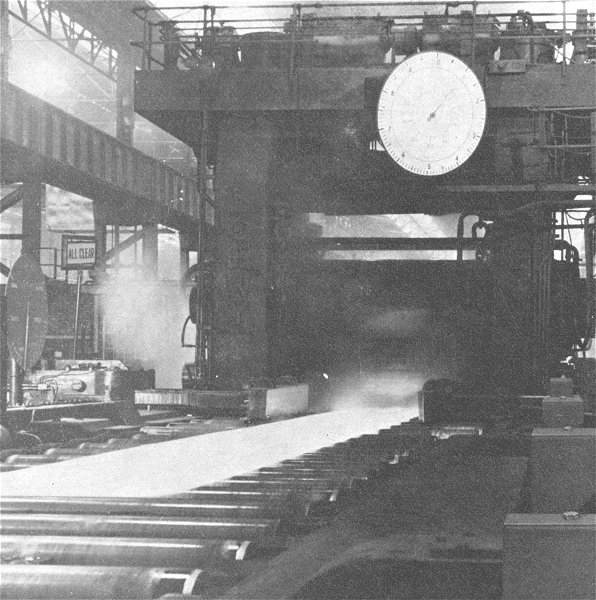

The Plate Mill. |

|

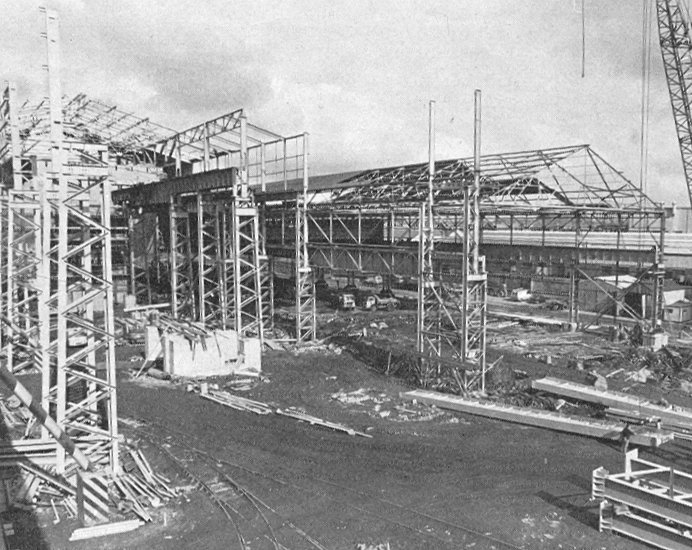

Building the electric

arc furnace bay, the minerals handling bay,

and the scrap handling bay. |

|

The second phase of development

included the installation of an electric arc furnace

at Brunswick Works. It was housed in a new casting

bay, on the outside of the existing bay. In November

1973, following the international oil crisis, a

second electric arc furnace was installed to reduce

the company's dependence on oil supplies.

The new

installation was designed by The International

Construction Company Limited; which had acted as

consultants in the major development scheme of

1956-59.

The electric arc furnaces were

5.8 metres diameter with a nominal capacity of 88.5

tons. They had 500 mm diameter electrodes and were

fed from transformers rated at 45MVA.

They were

equipped for automatic power input control and had

an interface facility for possible future computer

control. The new furnaces proved to be entirely

satisfactory in service.

|

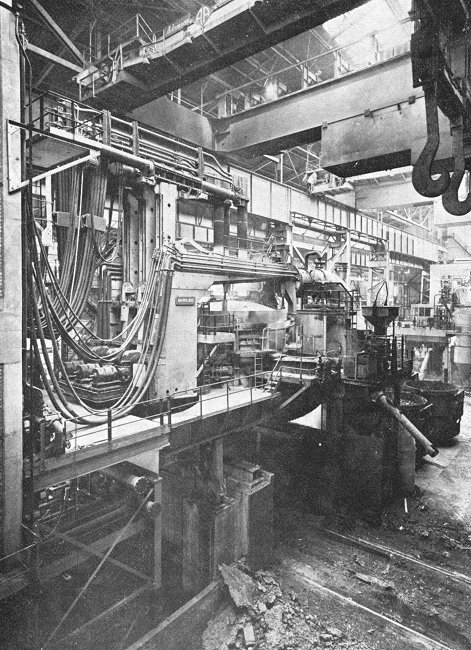

The electric arc furnaces. |

| The scrap handling bay was

re-sited and lengthened. It had four overhead

cranes, each equipped with a magnet. A new minerals

bay for the handling of lime and coke etc. was

added, alongside a new furnace bay that housed two

UHP electric arc furnaces, located 7 metres above the

ground at charger platform level. Slag from the

steelmaking process was tipped into a shallow

depression from where it was removed by a traxcavator, a combined tractor and

excavator. |

|

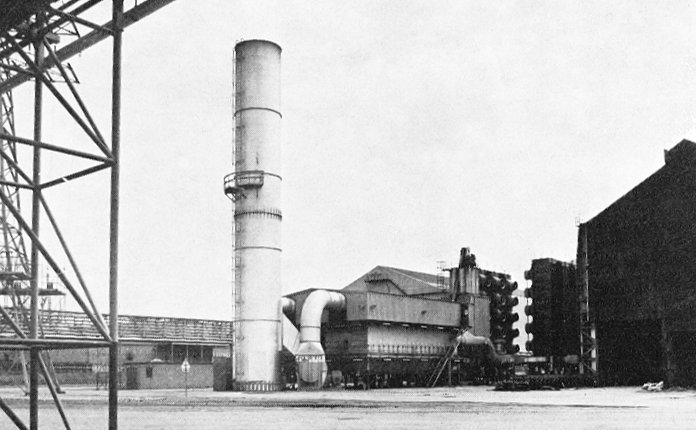

The fume cleaning plant. |

| Other new

buildings included a state of the art fume cleaning

plant, and a new electricity sub-station. The first

of the two new furnaces began operating on 1st

December, 1975, after the Central Electricity

Generating Board had installed a 33kV supply. The

second furnace went into service on 30th March,

1976. At the same time a new section mill was built

at Monway Works, which began operation in December

1975. |

|

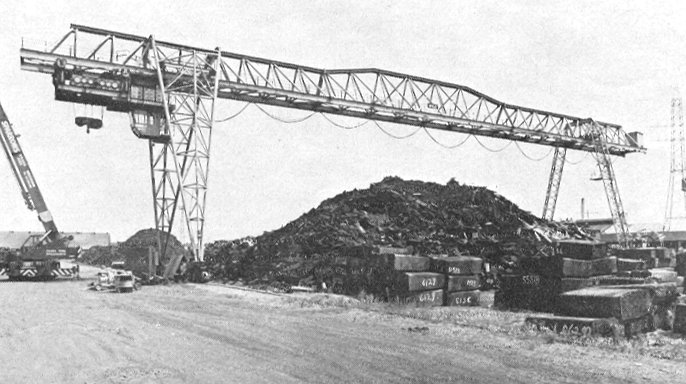

'Goliath' materials handling

crane. It could travel over 230 metres and covered

an area of 3.8 acres. |

|

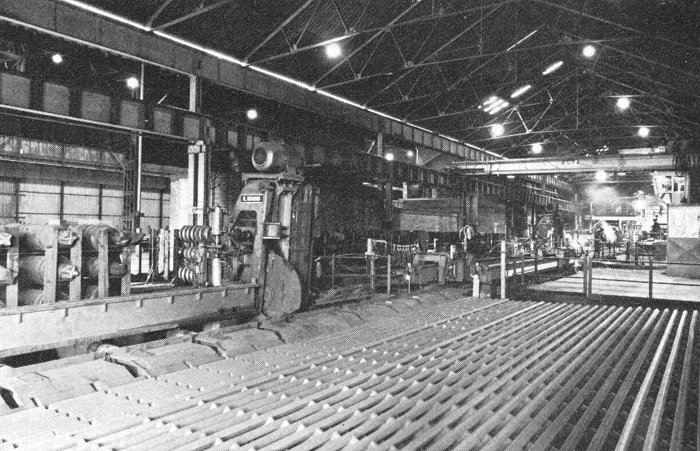

The walking beam cooling bed

and the saws, in the section mill at Monway Works.

|

|

The section mill at Monway

Works. |

| On-line computer planning of

slab production in the primary plate mill began to

be used in order to increase the output by

determining each slab length after an ingot was

rolled, but before it was cut, resulting in an

increase in throughput without a loss of overall

yield. A new computer building was erected to house

two Digital Equipment PDP 11/40 computers, as well as

the firm’s existing ICL 1902A, which was used for

planning, invoicing, and general accounting. The new

computers were connected to 36 terminals, situated

at various points in the mill and soaking pit areas,

as well as in the steel plant, laboratory, and

planning department. Details of ingots cast and

reheated were fed to the computer which then

determined optimum slab dimensions and issued

instructions through display panels to the rollers,

shear operators, and other personnel concerned. |

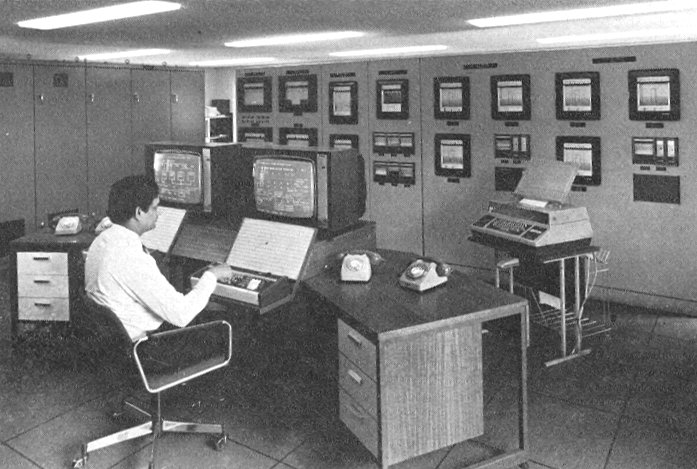

The services monitoring

control room. On the left in the background is the

computer, on the right the strip chart display

panel, and in the foreground the control desk, VDUs

and one of two teleprinters. |

| A centralised works services

monitoring and control system had operated since

1965, based on conventional instrumentation. By

1973, due to the considerable expansion on the site,

it needed expanding and updating. A small computer,

a printer, and several terminals were purchased for

the purpose. Details of any plant faults could be

printed out, and operators could see clearly and

immediately when a fault developed. In the early 1970s the company

purchased the old Monway Canal Branch that had been

used for the delivery of coal to a Lancashire boiler

range, and more recently as part of the works water

supply.

The canal now formed a physical

barrier between the three main works areas and was

limiting further development. It was drained in

sections and back filled. A reservoir was

constructed, adjacent to the new water services pump

house for the electric arc furnaces, which was

connected by a 0.75 metre diameter pipe to the main

canal.

As a result of the development

scheme, the number of people working on the site was

reduced from 1,800 to 1,725. The resulted in only

four redundancies, 36 men were redeployed, and 35

accepted voluntary redundancy.

The redevelopment scheme, completed in 1976, cost around £11.3 million.

|

|

|

|

|

|

Return to

Take Over |

|

Return to the

beginning |

|

Proceed to the Factory

in the Late 1970s |

|