| The Patent Shaft

& Axletree Company - Take Over After the

acquisition of Monway Works and Old Park Works, the

company continued to prosper under the management of

Thomas Walker.

The local iron ore contained too high a percentage

of phosphorus, for reliable use with traditional

smelters. This problem was overcome in 1879 with the

invention of the Gilchrist-Thomas process, in which the

converter had a lining of dolomite brick. The dolomite

combined with the phosphorus to leave good quality

steel.

The Patent Shaft acquired a furnace using this

process in 1882, but difficulties led to its temporary

abandonment. The company also used Siemens open-hearth

regenerative furnaces, where the waste gases were used

to heat the air for the blast. The furnaces were lined

with refractory dolomite brick to allow them to

efficiently use the local iron ore. They also had

another advantage, they could use scrap.

At this time the company also had four 12 ton

traditional Bessemer converters, and a 12 ton and an 8

ton Bessemer, both lined with dolomite brick. The slag

from the furnaces was sold to Germany for use in

agriculture. In 1885 the company built the world's first steel

bridge at Benares on the Ganges, which used 6,500 tons

of steel, and in 1900 built a 7 span bridge at Natal in

just 2 months. |

|

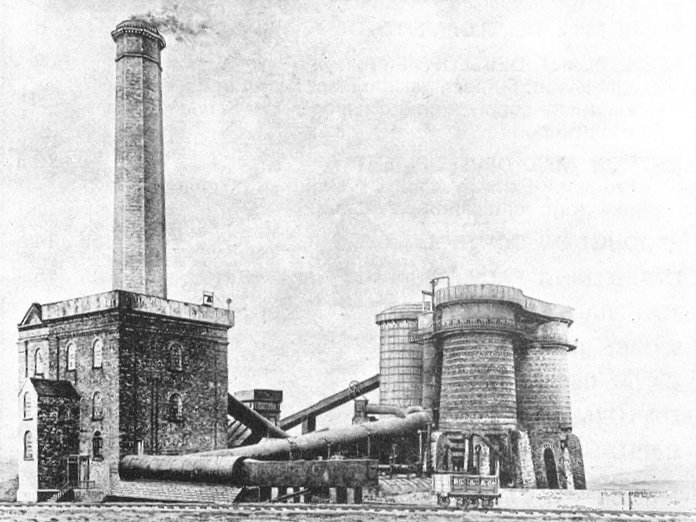

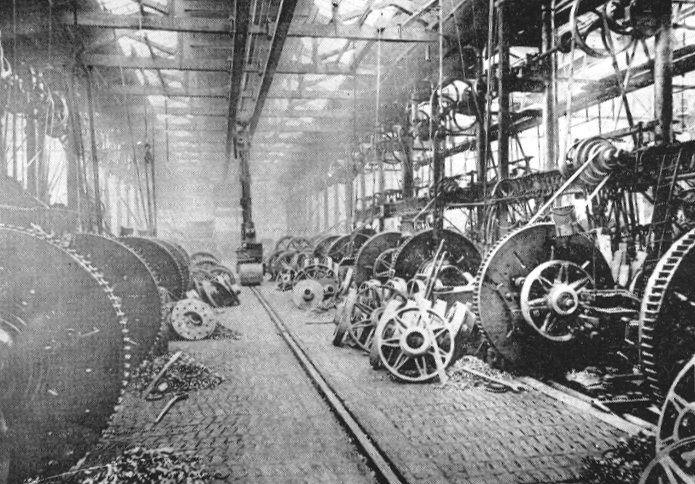

The Patent Shaft blast furnace

in about 1890. |

| The company had some financial difficulties in

the late 1880s and so in 1889 a new company, using

the same name was formed to take over the assets.

The difficulties continued for a few years, during

which time new plant and machinery was added to the

factory. In 1891 work began on a new plate mill, and

a mill for rolling steel channels at Brunswick

works. In 1896 a new cogging mill and soaking pit

were added. All of the new plant continued in use

until 1958/59. |

|

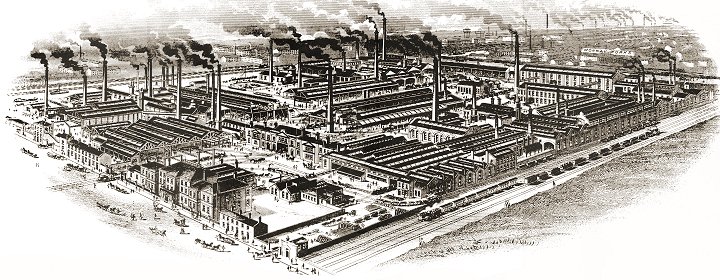

Brunswick Works in about 1895. |

| On the 18th April, 1902, the Patent Shaft

& Axletree Company became part of the Metropolitan

Amalgamated Railway Carriage and Wagon Company

Limited, which had been proposed by Mr. Dudley Docker,

who had joined the Patent Shaft's Board in 1899. The

new company was formed with a share capital of £1.5m

to take over the business of the Metropolitan

Company and to amalgamate with the following rolling

stock companies: The Ashbury

Railway Carriage and Iron Company Limited, Brown and

Marshall's Company Limited, The Lancaster Railway

Carriage and Wagon Company Limited, The

Willingsworth Iron Company Limited and The Oldbury

Railway Carriage and Wagon Company Limited.

The Patent Shaft became became part of a new

conglomerate. From then-on until nationalisation in

1951, the Patent Shaft was wholly owned by the

Metropolitan Company, and was treated as one of its

branches. |

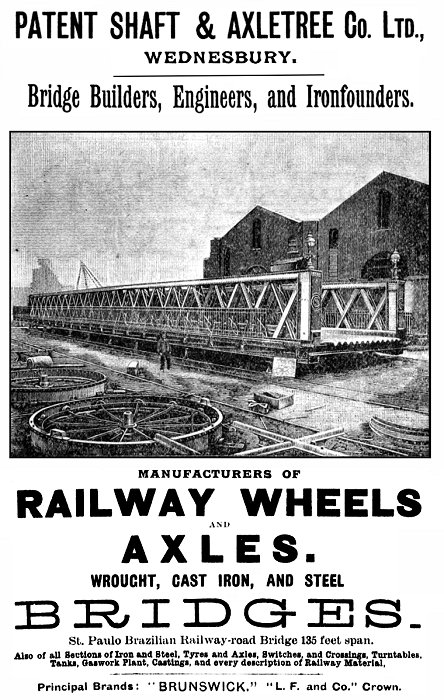

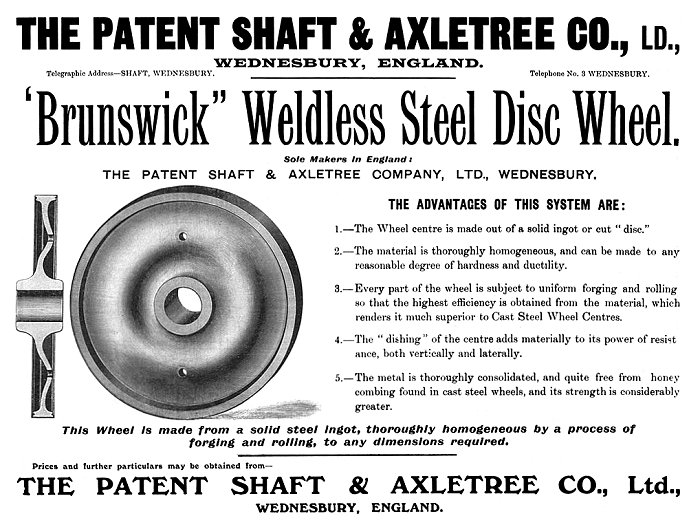

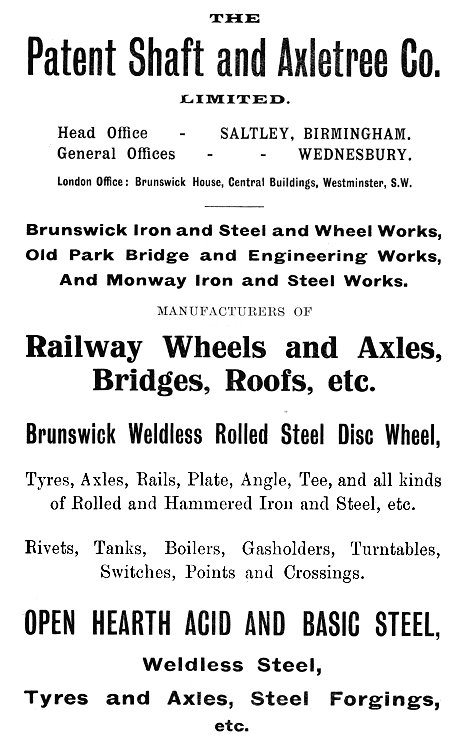

An advert from 1900.

An advert from 1902.

An advert from 1909.

| After the take over a considerable amount of

development work was carried out including new

buildings at Monway Works and Brunswick Works. The

company spent

over £300,000 on the new buildings, and new plant, including electrically

driven machinery. The workforce greatly increased

in size, and the new business prospered. Many of the double-decked trailers that

were pulled by the local steam trams were built at the

works during the early years of the 20th century. |

|

An advert from 1909. |

The business continued to thrive, even during the

severe depression in 1907 when the annual profit was

over £300,000. In 1911 the company received an order

from the Great Central Railway for 6,500 wagons, the

frames for which were made at the Patent Shaft.

At the time, the Patent Shaft

produced a wide range of products including: railway wheels,

axles, patent weldless steel spoked wheels,

rolled iron plates, steel plates,

steel bridges, wrought iron and cast iron

girders, constructional iron and steel work,

wagon under frames, plant for gas works and

water works, and every kind of pressed work.

Railway bridges had been built for

all of the railway companies in the UK, and the company

also built some of the largest bridges in Egypt, India,

Japan, South Africa, and South America.

In 1912, Dudley Docker, the company's

Chairman, proposed changing the name of the company from the

Metropolitan Amalgamated Railway Carriage and Wagon Company

Limited to the Metropolitan Carriage, Wagon and Finance

Company Limited. |

|

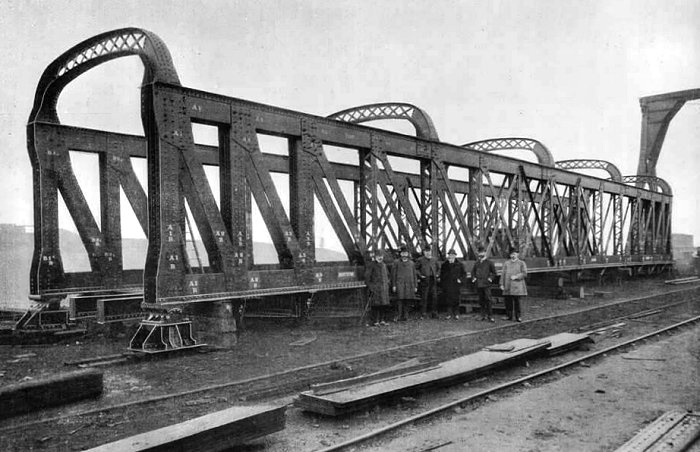

One of the spans built for the

bridge over the Tugela River in South Africa, by the

Patent Shaft in 1899. |

The old Patent Shaft turntable

that is in the town of Realicó, in the province of La

Pampa, Argentina. Courtesy of Arch. Néstor D. Dalmasso. |

|

The makers plate that is on the

turntable above. Courtesy of Arch. Néstor D. Dalmasso. |

|

An advert from 1916. |

During the First World War the

company concentrated on war work, and as a result made

record profits. Products included gun carriages, railway

mountings, and tanks. The tanks were built at Old Park

Works, and shell steel was produced at Brunswick Works.

In 1919 it was decided that the

whole of the wagon-building side of the business at Old

Park Works should be managed by the Metropolitan

Company, and the bridgework and other activities carried

on there by Patent Shaft gradually diminished.

In 1919 the Metropolitan Company

was purchased by Vickers Limited of Sheffield, and in

1929 Vickers Limited and Cammell Laird & Company of

Birkenhead, amalgamated their steel making and carriage

building businesses.

This resulted in the formation of

the Metropolitan Cammell Railway Carriage and Wagon

Company. The take

over had one immediate effect at Wednesbury, the

separation of Old Park Works and the Patent Shaft.

Vickers, who had already been using part of Old Park

Works took over the remainder.

In the early 1920s it was also

decided that the manufacture of wheels, tyres, and axles

at should take place at Taylor Bros & Company Limited,

at Trafford Park, later a subsidiary of English Steel

Corporation. That side of the company's business

gradually diminished and finally ceased, so that

steelmaking and rolling were its sole remaining

activities. |

|

The machine shop in the 1920s.

Development between the wars was

limited, owing to continued depression in the steel

industry, but a new open hearth steel plant, with three

75 ton basic furnaces was added, followed by a fourth furnace in

1938. |

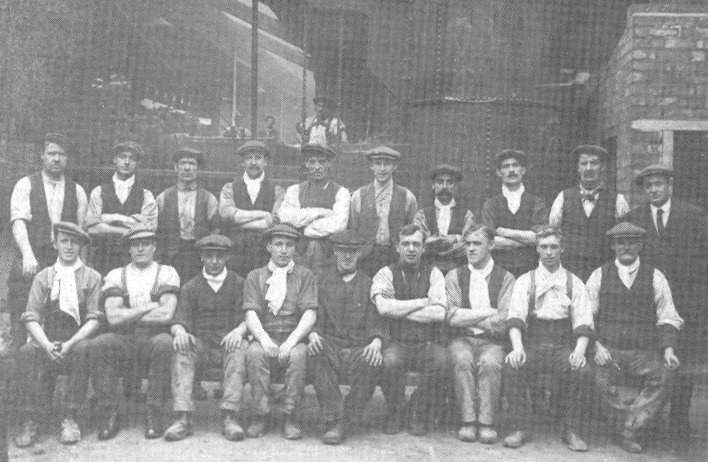

A letterhead from 1929.

A group of employees.

| A single 40 ton furnace from the old plant was

retained and operated as an acid furnace. A scheme for

the electrification of the 10 inch and 15 inch section

mills, and a new furnace for the 15 inch mill was

finally carried out between 1946 and 1951. In 1949 Old

Park Works were sold outright to Metropolitan Cammell to

become part of the

Metropolitan Cammell Railway Carriage and Wagon Company

Limited, which also had factories at Elmdon, Saltley, and

Washwood Heath.

In 1951 the

company was nationalised under the Iron and Steel Act

1949, but returned to private ownership in 1956 when 75% of its shares were

purchased by Cammell Laird, and the remaining 25% by

Metropolitan Cammell. In 1959 its name was changed to

the Patent Shaft Steel Works Limited, and by 1961 the

company had 1,500 employees.

In the late 1950s a development scheme costing £8.75

million was undertaken with the aid of loans from the

shareholders, and from Finance Corporation for Industry

Limited. As part of the scheme the existing

four 75 ton furnaces were converted from producer gas to

oil firing, and the old 40 ton acid furnace was

scrapped. The 10 inch mill was closed down, and two 75 ton oil fired furnaces were added.

By this time the 15 inch section rolling mill

produced over 300,000 tons of steel a year.

As a result, annual output

increased nearly threefold to over

300,000 tons of ingots, 200,000 tons of plates, and

30,000 tons of bars and sections. |

An advert from 1949. |

| Because the company now concentrated on steel

making, its name was changed to The Patent Shaft

Steel Works Limited, on 8th May, 1959. In 1962-63

improved finishing facilities were provided for the

new plate mill, and in 1968-69 new buildings,

cranes, and a reheating furnace for the 15 inch mill

were added. |

|

The Patent Shaft offices. |

An advert from 1954.

An aerial view of Patent Shaft's Brunswick

Works.

|

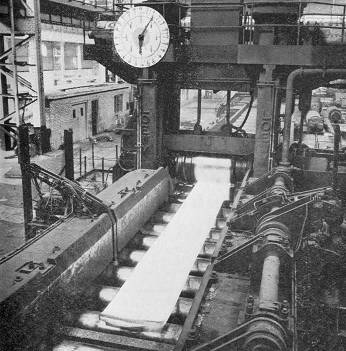

The blooming and slabbing mill at the

steelworks. |

On 1st January, 1969 Cammell Laird acquired

the whole of the Vickers interest in the

Metropolitan Company, so that Patent Shaft

became a wholly-owned subsidiary of Cammell

Laird. Shortly afterwards, the Patent Shaft

share and loan account balances held by the

Metropolitan Company were transferred to the

parent company.

In 1969-70 an additional reheating furnace,

increased slab storage and stacking facilities,

and further improved finishing facilities were

provided for the plate mill, and the steel plant

capacity was increased by strengthening the

building, installing a new 157 ton casting bay

crane and converting the two newer furnaces to

118 tons capacity. Four of the other furnaces

were converted to 98 tons capacity, and the

output greatly increased.

|

|

On 25th September, 1970, following a

reorganisation, Cammell Laird & Company Limited

was renamed The Laird Group Limited. Record

outputs were achieved in 1973 when 372,146

tons of ingots, 233,745 tons of plates, and

43,676 tons of sections were produced. |

|

|

|

|

|

Return to Old

Park Works |

|

Return to the

beginning |

|

Proceed to

Development Schemes |

|