|

West Bromwich grew rapidly in the

18th, 19th, and 20th centuries, thanks to the large

number of factories that opened in the area, providing

employment for the local population.

There were many industries,

including:

|

Aircraft accessories, Axles and Axle Trees

Bearings, Boiler Compositions, Bolts and

Nuts, Bottle makers, Box-Irons

Bricks, Bridges, Bright Drawn and Rolled

Steel, Cabinet Making

Chemicals, Collieries, Concrete Products,

Confectionery

Electrical Fittings, Engineering, Forgings,

Foundries, Furniture, Gauges

Glass, Grates, Holloware, Hydraulic

Machines, Iron Foundries, Ironmongery

Mineral Waters, Nails, Paint, Pattern

Makers, Plastics, Printing, Safes,

Springs, Tools, Trailers, Tubes,

Typewriters, Washers, Weighing Machines |

|

|

|

|

Read about some of the

larger industries and companies |

|

|

Foundries

and Pattern Makers |

|

|

Springs |

|

|

Jensen

Motors Limited |

|

|

J.

Brockhouse & Company Limited |

|

|

Archibald

Kenrick & Sons Limited |

|

|

George

Salter & Company Limited |

|

Kenrick & Jefferson Limited.

The printing business opened in

October 1878, when John Arthur

Kenrick, a member of the well-known hardware family,

formed a partnership with Frederick Thomas Jefferson, a

local solicitor, to acquire the business of 'The Free

Press', a bankrupt Liberal newspaper in West Bromwich.

Kenrick & Jefferson Limited

was incorporated as a private limited company on the 6th

January, 1900.

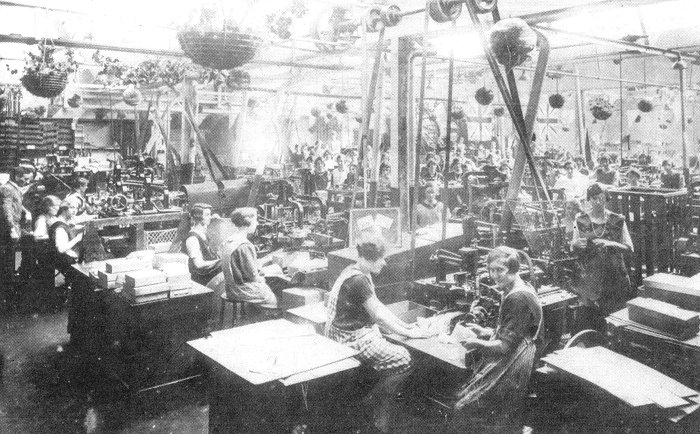

The envelope factory in 1925.

Frederick

Jefferson quickly developed the printing side of the

business, which soon moved into office equipment,

business stationery, loose leaf binders, filing systems

and even office furniture. 'The Free

Press' newspaper closed in 1933.

By the 1950s there were over

100,000 customers in Great Britain and abroad,

benefitting from the excellent printing quality, thanks

to the installation of the latest and finest plant. The

composing, letterpress and lithographic departments were

capable of handling both small and very large contracts.

Four large binderies employing over

500 people dealt with the handling of system stationery,

renewal leaf binders, filing and card index equipment

and Carbotyp stationery for simplifying clerical

operations.

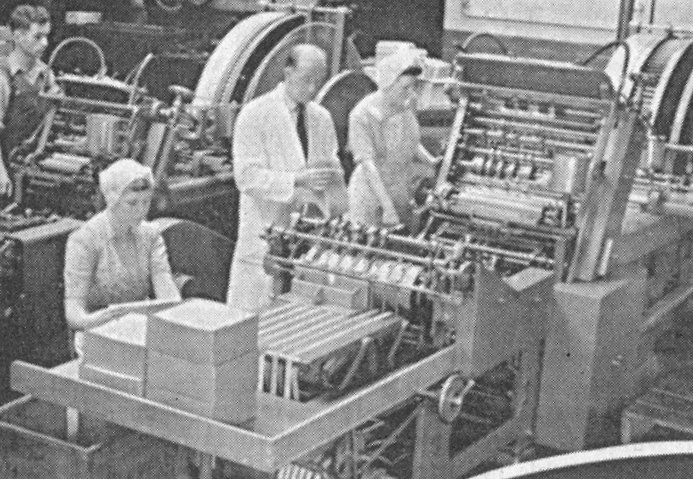

A battery of fast-running

letterpress machines.

The department devoted to relief

stamped stationery is one of the largest, if not the

largest, of its kind in the world, thanks to the hundred

or so, modern relief stamping presses that are

constantly in operation. There is also a well-equipped

envelope factory, where envelopes from the smallest to

the largest commercial sizes are available direct to

customers in a wide range of materials.

An envelope making machine.

The firm’s advisory department

provided recommendations on business organisation and

routine and the direct advertising department offered

suggestions for all kinds of advertising literature. In 1971,

the firm acquired Manchester-based, Norbury Lockwood,

manufacturer of calendars and printed stationary.

The 1883 building in High Street.

In

1995 to 1997 the firm sold off everything except its

envelope business, based on another site in the town.

That was also sold in 1999 and traded as Kenrick and

Jefferson Envelopes Limited. The High

Street premises was derelict for several years and by

the autumn of 2001 had been demolished (except for the

1883 building) for redevelopment as a shopping and

leisure centre.

The once-familiar building on High

Street that was demolished at the turn of the century. |

|

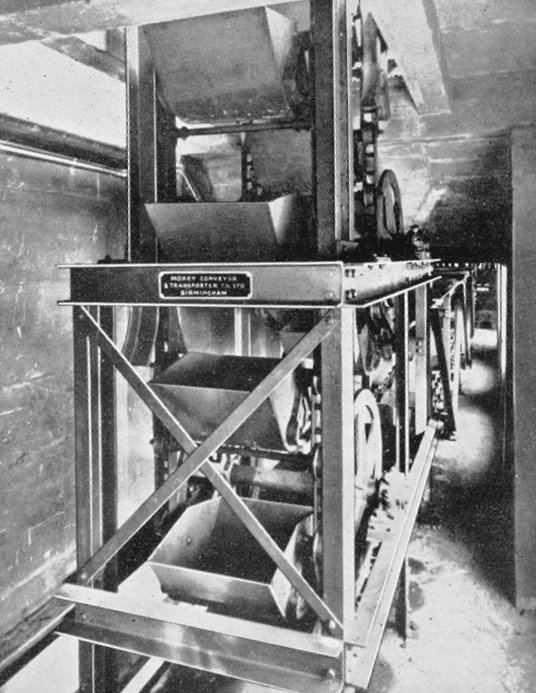

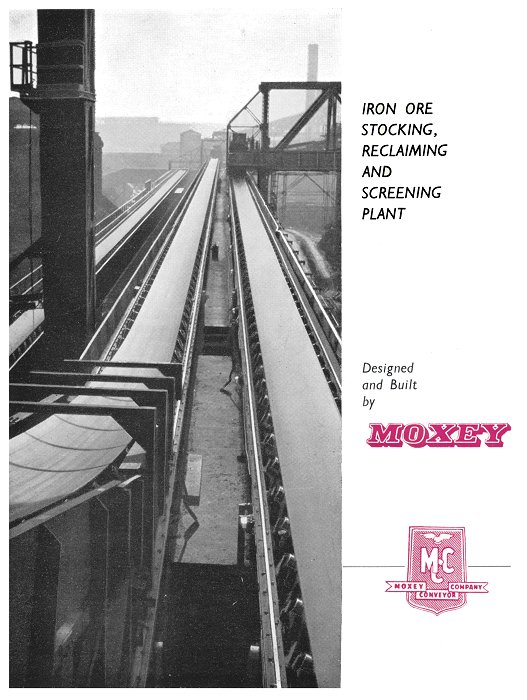

Moxey Conveyor & Transporter

Company Limited.

The company, which specialised in

the design and manufacture of bulk handling conveyor

plant, primarily for the steel industry, opened a new

factory at West Bromwich in 1954. The site, covering

eight acres, included the factory with a floor area of

40,000 square feet. Building work began in May 1954 and

the factory opened in 1955. By October of that year the

production area had been extended to cover around

100,000 square feet.

Apart from conveyors to handle iron

ore, coal, coke, grain and gravel, plant was designed

for the storage of railway wagon springs, the handling

of bicycle saddles, and whale meat processes in whaling

ships.

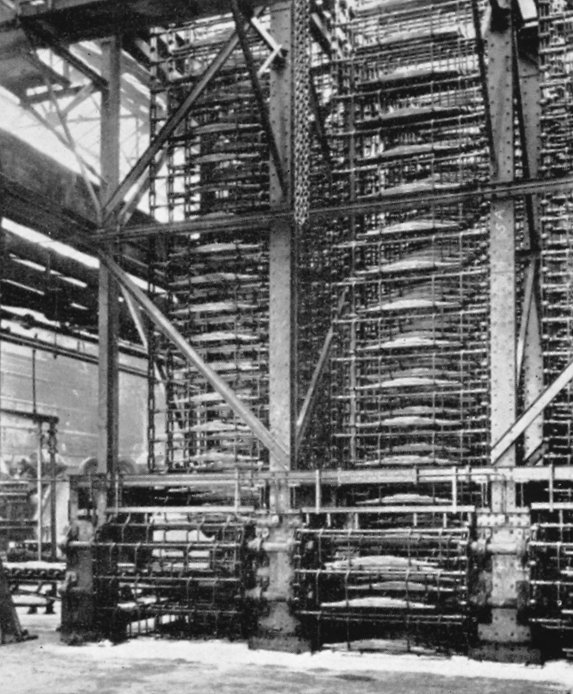

A Moxey gravity bucket conveyor

for handling coke.

A Moxey storage tower for railway

laminated springs.

| An advert from the

mid 1950s. |

|

|

|

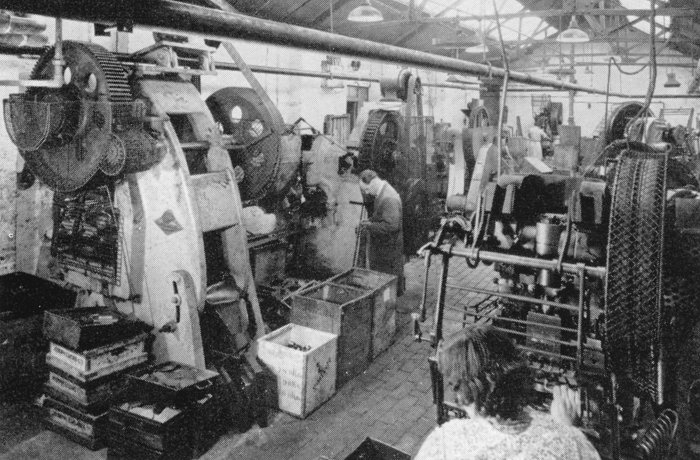

Pasco Limited.

Pasco’s factory opened in about

1920 for the manufacture of precision pressings. After

the Second World War, large power presses of up to

eighty tons capacity were installed, which enabled the

firm to undertake the production of a vast variety of

fittings and components for the motor trade.

The plant was capable of handling

complicated pressings involving a large number of

individual operations and the manufacture of fittings

for brushes, chisels, spades, shears and many similar

articles. Components for the foundry trade are also

produced. The firm regularly carried out contracts for

the Admiralty and other Government Departments and

exported pressings to Australia and New Zealand.

Inside the Pasco factory. |

|

An advert from the mid 1950s. |

|

Ash & Lacy

Limited.

The firm, founded by Joseph Ash, began life in

1857. He was joined in 1864 by John Pierce Lacy to

form Ash & Lacy. In 1936 the firm moved from Great

Bridge, to a factory at

Black Lake, West Bromwich. The firm’s head

office was in Meriden Street, Birmingham. It became

a private limited company on the 5th December, 1917,

specialising in galvanised corrugated sheets for the

Dutch barn and constructional engineering trade,

supplying sheets that could be curved or cut to the

requirements of any roof or building.

Steel gutters of almost any shape or thickness were

made on powerful brake presses which also carried

out many other types of heavy bending work. The

sheet metal work included articles such as

galvanised coal bunkers, stovepipes, revolving

cowls, corn bins and garden wheelbarrows. The firm

has been extremely successful and has a head office

in Bromford Lane, West Bromwich, with many customers throughout the world.

It now produces a range of building materials

including steel frames, fabrications and cladding at

several locations. |

|

Hills (West

Bromwich) Limited.

Hills was founded in the early

1930s as Hills Patent Glazing Company Limited. The firm

broadened its activities by making windows, lanterns,

decklights, domes, office partitions, etc. In 1936 the

firm founded Universal Steel Doors, Limited, who

manufactured large sliding doors for aircraft hangars

and later complete aircraft hangars at the Kastrup

Airfield, Copenhagen.

At the beginning of the Second

World War, the firm carried out contracts for Bailey and

other military bridging equipment, rocket guns, pulley

blocks, invasion gear, light gun mountings and founded

an associated company called Chain Developments Limited,

for the manufacturing of electrically-welded steel

chains for the Admiralty and for special tanks used by

the Armoured Corps.

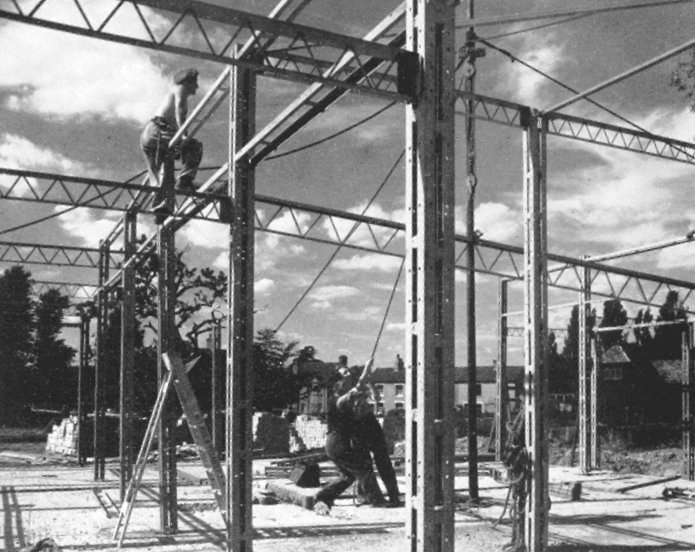

During the war, Hills developed the

'Presweld' system of building construction, which by the

end of 1945 had become well established. It used a

lattice type of construction consisting of built-up

beams and sub-assemblies with a high degree of

prefabrication, so as to reduce skilled work during

erection.

In 1946, the private limited

company, Hills (West Bromwich) Limited was formed and

the Hills Presweld system was first applied to steelwork

and later to other materials, such as concrete, glass

and plaster. Initially, the system was applied to

domestic housing, where the advantages of speed of

erection, with the roof completed very early on,

out-weighed the extra cost of a steel frame. It began to

be used for the erection of schools, which at the time

were in demand. Hills took a leading part in the

post-war school building programme and were associated

with about one-fifth of all the new schools built. 'Presweld'

has also been applied to factories, canteens and office

blocks.

Assembling Hills' Presweld components for a new school building.

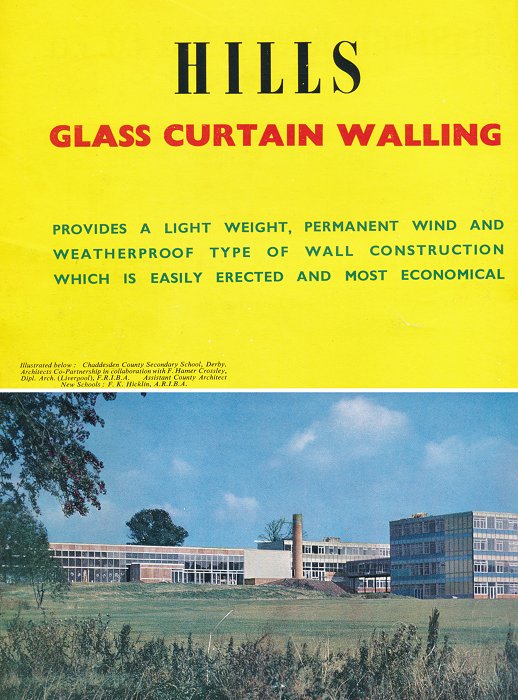

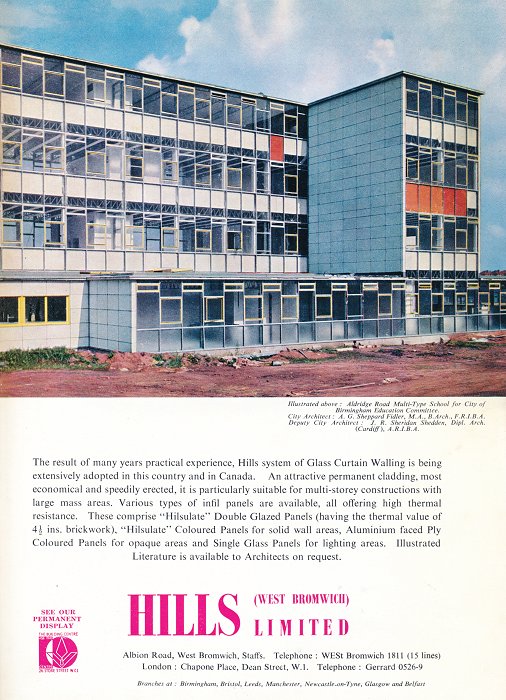

In the late 1940s, Hills developed

Glass Curtain walling, which uses a framework of

horizontal and vertical rails attached to the main

structure, whether it be a steel frame, brickwork or

reinforced concrete. Into this framework are fitted

large panes of glass with any desired degree of opening

lights and combinations of solid or opaque panelling as

the architect may desire. The finished wall of glass is

both wind and weatherproof and can also incorporate any

desired degree of insulation and permanent colour that

may be wanted. The infill panels are marketed under the

name of 'Hilsulate' and are also available for other

building applications. Here again, the company is in the

forefront of new development, having already completed

Glass Curtain Walling contracts for a number of schools,

office blocks and multi-storied flats at home and

abroad.

The firm developed another new form

of construction called 'Hilcon', consisting of pre-cast

reinforced concrete wall and floor units and included

the 'Hilsulux' roof construction system, using standard

woodwool or concrete slabs supported on steel purlins

and covered by bituminised felt.

Another product was power operated

roof ventilating shutters which virtually gave open-air

conditions at the touch of a button and were

indispensable to foundries, rolling mills and laundries,

etc., where the rapid clearance of heat, smoke and other

fumes was a problem. All the steelwork produced by the

firm was normally galvanised in Hills’ "hot dip" plant,

one of the largest of its kind in the country.

|

An advert from the mid 1950s. |

| An advert from the mid 1950s. |

|

Hills (West Bromwich) Limited,

expanded from a small private company to an enterprise

controlling six factories, including three at West

Bromwich and eight branch offices. In addition, a

subsidiary company was formed in Canada to market and

establish the company's products, despite intense

American competition.

In the 1960s things started to go

wrong and the company went into liquidation in 1962.

| From the London Gazette:

Hills (West Bromwich) Limited

Notice

is

hereby

given

pursuant

to

section

299 of

the

Companies

Act

1948

that

a

General

Meeting

of

Members

and

a

Meeting

of

Creditors

of

the

above

Company will

be held

at

Chamber

of

Commerce

House,

75

Harborne

Road,

Edgbaston,

Birmingham

15, on

Friday,

the

25th

October

1963

at

3 o'clock

and

4 o'clock

in

the

afternoon

respectively

for

the

purposes

of

having

an

account

laid before them showing

the manner in which the liquidation

has

been conducted and

the

property of

the

Company

disposed

of

during

the

first

year

of

the

liquidation,

and

of

hearing

any

explanations

that

may be given by the Liquidator.

A Member entitled

to attend and vote at the above

Meeting may appoint

a proxy to attend and vote

instead of him.

A proxy

need not be a Member of the

Company.—Dated this

30th

day

of

September

1963.

A. S. Maddison,

Liquidator. |

|

|

|

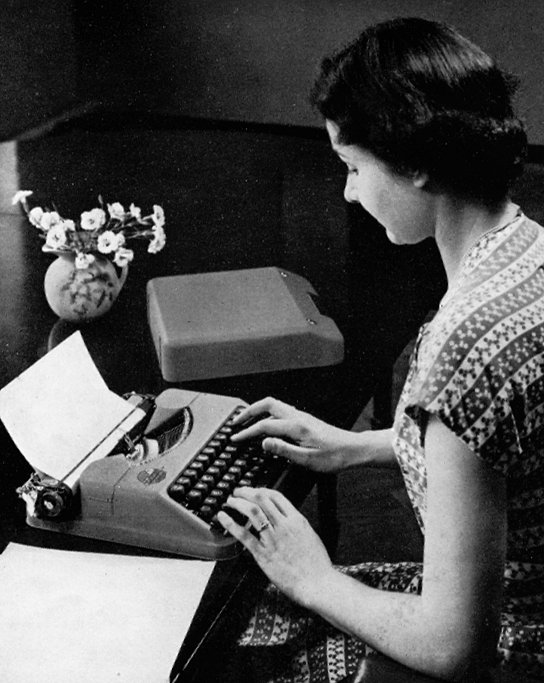

British Typewriters Limited.

It began in 1935 when it acquired

the sales and manufacturing rights to 'The Empire'

typewriter from George Salter. The business began in a

former grocery warehouse in Victoria Street and produced

a new typewriter called 'The Baby Empire'. Up to 70

machines were produced each week and things went well

until the outbreak of war. The firm's building was badly

damaged in air raids in November 1940 and so production

ceased until after the war.

Any machinery that could be

salvaged was moved to part of the Kenrick & Jefferson

site, where the firm was engaged

in war work, producing aero engine rods for

Armstrong Siddeley, aero engine flame traps for the

Rolls Royce Merlin engine, as well as sights and trigger boxes for

anti-tank weapons.

The firm moved to the former Hudson

Works in Queen Street and Pitt Street, which had been

used by the Civil Defence and Fire Services. Typewriter

production began there in 1946. The Empire Aristocrat

model was introduced in 1948 and over one million of

them were produced. |

|

The Empire Aristocrat. |

In

the mid 1950s an updated compact model was produced,

which featured a more efficient and convenient design,

with a normal size roller, to allow the easy insertion

of paper and improved printing of type.

There was an

eraser table for the easy correction of typing errors,

specially designed plastic key tops with endurable

lettering, shaped to suit the fingers and even touch

over the whole keyboard.

In 1958, Smith Corona acquired British Typewriters,

Limited.

Manufacturing continued until the market was

being undermined by inexpensive imports from the Far

East, which resulted in the closure of the West

Bromwich, plant in 1981. |

| Braithwaite & Kirk.

The firm started life as

Riley, Fleet & Newey, in 1848, as an engineering

company at Crown Works, Swan Village. It was formed by

George Newey, Thomas

Fleet and James Riley, all subcontractors in the

engineering industry. By 1861 the firm was producing a

wide variety of products including wrought-iron steam engines, boilers,

gasholders, purifiers, tanks, bridge and girder work, iron

roofs, and canal boats. The business also produced evaporating and

sugar pans, water barrels, barrows, and miners' tools.

In 1884 the firm became Braithwaite & Kirk, engineers and contractors,

based at Crown Bridge Works, West Bromwich, which was

located on the Balls Hill Branch canal Just off Henry

Street and south of Ryder Street.

In 1912 the firm became Braithwaite

& Kirk and they received an order for 24 iron composite

canal boats. A year later

Braithwaite & Company Structural Limited was formed

as a subsidiary company in India.

Braithwaite & Company also opened another factory at

Newport, Gwent, called Neptune Works.

|

An advert from the mid 1950s. |

Each factory had the most modern machinery and provided

excellent training facilities for young men entering the

structural steelwork trade. The company’s apprentices

were encouraged to study at technical colleges, and two

scholarships were available at Birmingham University.

Many apprentices progressed to positions of trust and

were responsible for the supervision of large contracts

that were carried out by the company in all parts of the

world.

The company joined

forces with other businesses to form the

Braithwaite Group of Companies. In addition to structural steelwork

and bridgework, the business was well known for the

fabrication and erection of wharves, piers, jetties,

cast-in-situ using "Screwcrete" piles and pressed steel

sectional storage tanks.

In 1978 to 1980 all UK

operations were moved to South Wales and the

firm became part of the Rowecord Group,

which operates from Neptune Works. The firm

is now known for the design and supply of the largest

glass reinforced plastic (GRP) and

Steel water storage tanks in the world. |

|

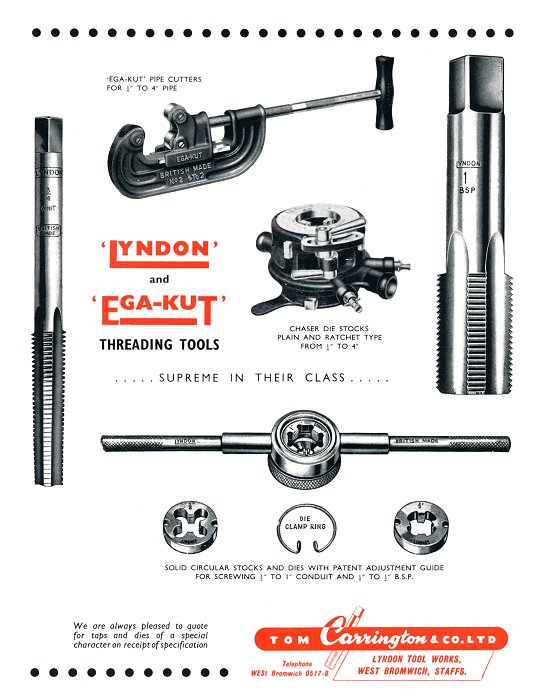

| Tom Carrington & Company Limited. Tom Carrington started in business,

in a small workshop, before the First World War, making

taps and screwing tackle under the names of "Lyndon" and

"Ega-Kut".

The business was extremely

successful prospered and Lyndon and Ega-Kut products

were known and used throughout the world. The founder

retired and handed over the business to his son Tom, who

maintained the firm's reputation for quality and

accuracy, while increasing the scope and size of the

business.

The range of products increased and

the company manufactured taps, gauges and dies, chaser

die stocks, receders, pipe cutters and screwing

machines, which were widely used in the plumbing and gas

trades.

The business remained a family

concern, that became world famous for its "Lyndon" taps

and gauges and for its" Ega-Kut" threading tools, chaser

stocks and dies. In 1963, Tom Carrington & Company

Limited, moved to Egakut Works, Willenhall Lane

Industrial Estate, Willenhall Lane, Bloxwich. Where it

still is today. |

|

An advert from the mid 1950s. |

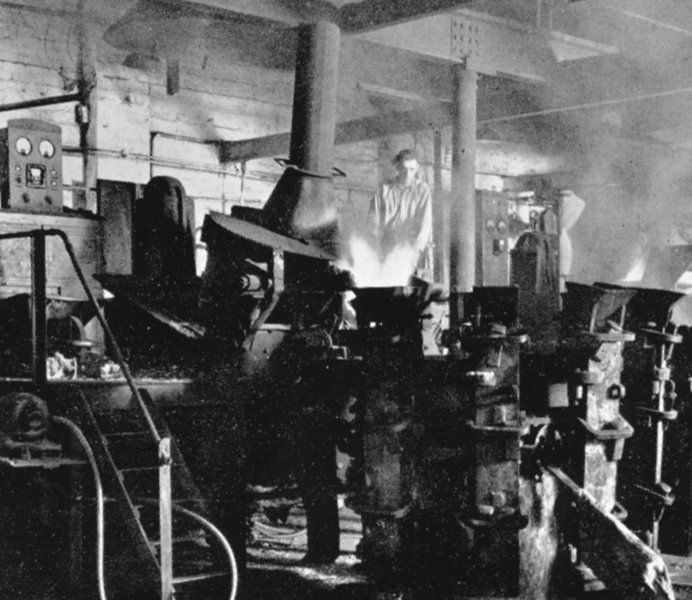

| Copper and Alloys Limited. The firm was founded in the late

1940s in West Bromwich and used production methods that

came from the continent. The business produced copper by

a refining process from low grade residues and scrap.

The basic product was copper, but advancing a further

stage and utilising their technique for refining copper

they also produced an extensive range of copper based,

non-ferrous alloys from brasses to gunmetals, phosphor

bronze, manganese and aluminium bronze, and high duty

nickel bronze for the Admiralty and special industrial

applications.

All the alloys were produced in the

forms of ingots, extrusion billets or rolling slabs, and

a high standard of purity was maintained by careful

treatment of raw materials and strict laboratory control

through every stage of production to final inspection.

The process also allowed the recovery of zinc oxide at

the refining stage, which apart from providing a highly

marketable product, had the joint advantage of reducing

air pollution in the vicinity of the factory to a

minimum. In an area as highly industrialised as West

Bromwich the importance of this will be readily

appreciated.

Melting brass in the electric

furnace department.

A new extrusion press was acquired

in the early 1950s, which was one of the largest brass

presses in the country. In the mid 1950s the factory was

extended with two new buildings, to extend the extrusion

capacity. In order to supply the increased number of

presses, the number of electric furnaces was increased

and the firm confidently looked towards a bright future.

|

|

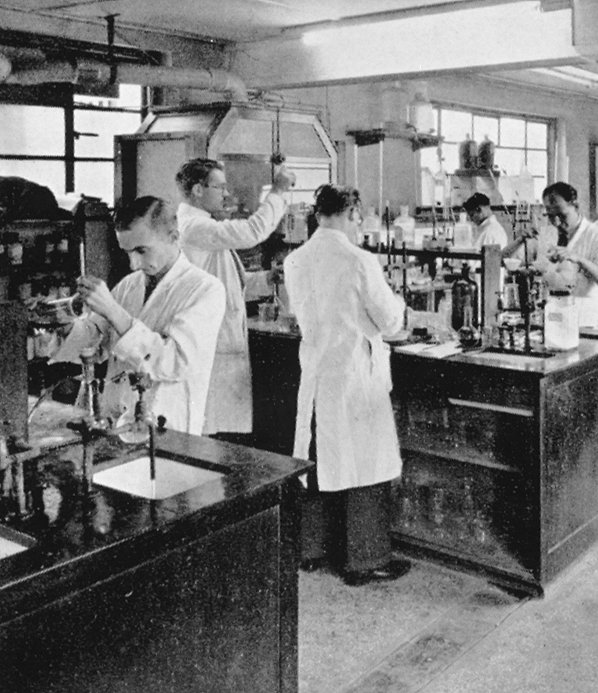

The chemical laboratory and

test station. |

|

An advert from the mid 1950s. |

|

C. B. Gurmin & Company Limited.

The business was founded in 1950

in Pikehelve Street, Golds Hill, West Bromwich, for the manufacture of a new type of key for the lock

trade. In the late 1940s, Chubbs and Albert Marston

Limited of Wolverhampton were having problems with the

manufacture of satisfactory malleable cast keys. Brian Gurmin,

a welding engineer, who was the brother in law of Bill

Williams, the owner of Albert Marston Limited, began to

look into the problem and soon found a solution.

Bill Williams encouraged Brian Gurmin

to set up his own company to make welded steel keys and

blanks, which were fabricated in steel from three pieces and

projection welded together. Each key was made with great

accuracy and could be put to a lock without any fitting

whatsoever, thereby saving considerable expense. A large

range of these keys was made and exported to all parts

of the world.

On of Brian Gurmin's main customers

was Yale. He also started to produce steel blanks

which were sold to the Willen Key Company.

Unfortunately, Gurmin & Company were unable to keep-up

with the demand and so Marstons looked round to see who

else was making welded steel keys and blanks. In 1955

they turned to Arthur Hough and Sons, in Essington, who

had started to make welded steel keys in 1953. Gurmin's

production problems continued and so in the late 1950s,

production ceased and the company's welding machine was

sold to Arthur Hough and Sons, in July 1960.

Gurmins branched out into the production of all types of

formed wire work, and supplied many of the leading

manufacturers of refrigerator and electric fires. Wire

mesh cloakroom equipment including kit lockers, shoe

baskets, etc., was manufactured for both school and

factory use. Milk bottle crates were also amongst the

many other items produced.

|

|

An advert from the mid 1950s. |

|

|

H. Geddes & Sons Limited.

The firm was founded in the early

20th century for the manufacture of export packing cases

and crates. There were three factories, one if West

Bromwich, another on Smethwick and a third in Oldbury.

Packing cases were produced with

waterproof lining and sealing of packing cases, tin

lining and the manufacture of cases to carry a colossal

weight.

The business was also a timber

merchant and so large stocks of wood were kept for sale,

including hardwood, plywood, seasoned hardwoods, doors,

imported softwoods and of joinery quality timber. There

was a mill available for any type of machining. The

business later moved to Dumblederry Lane, Walsall,

An advert from the mid 1950s. |

| The Fordath Engineering Company

Limited.

The business was founded in the

1920s to manufacture all types of foundry corebinders,

which with the addition of core oils provided short

baking characteristics, which enabled many foundries to

reduce their core shop costs, because of the short time

cycle required.

Fordath corebinders were sold under

the trade name "Glyso," and were exported to Holland,

France and South Africa.

Fordath also produced a range of foundry equipment

including the Fordath "New-Type" mixing Machine. In the

1950s, the plant was modernised and the factory extended.

|

|

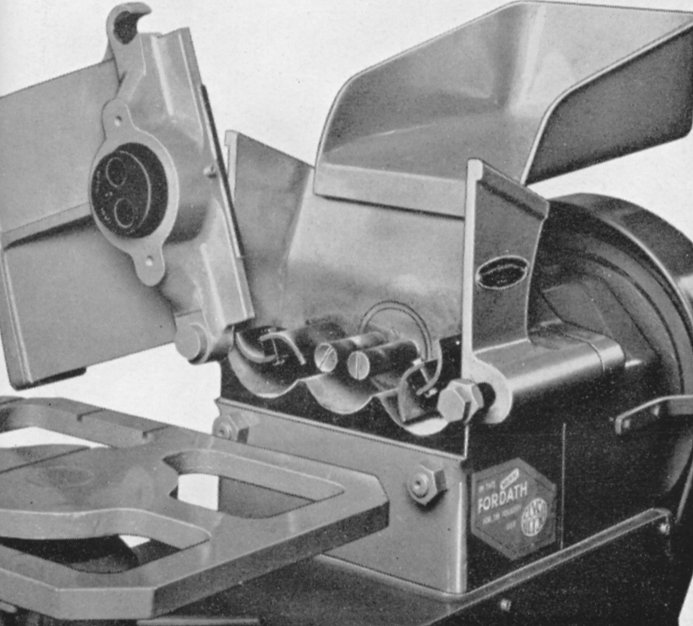

A Fordath multiplunger core

extrusion machine. |

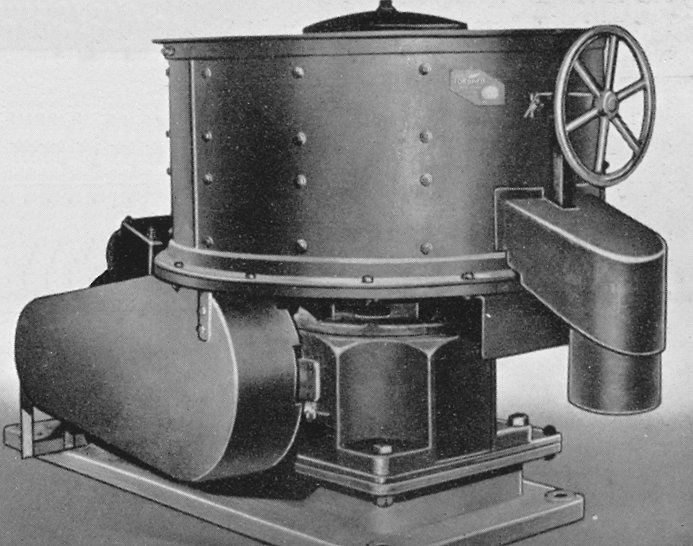

|

A Fordath mixing machine. |

|

An advert from the mid 1950s. |

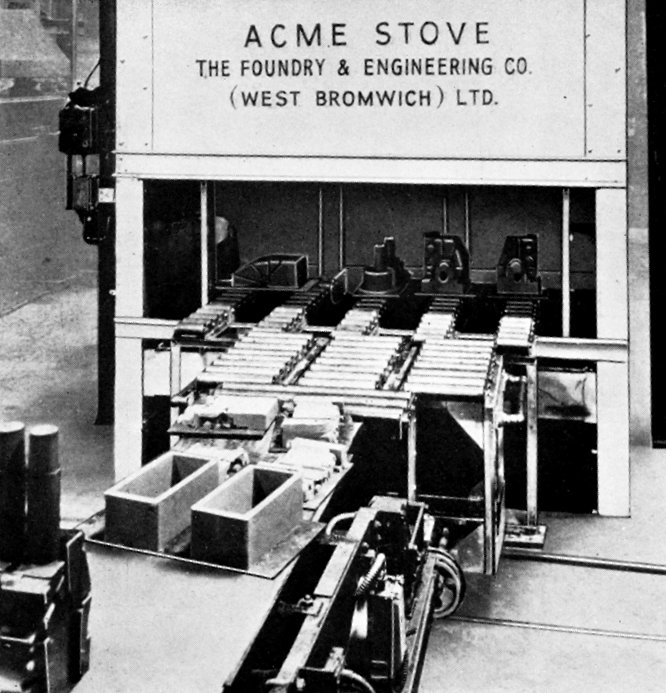

| The Foundry &

Engineering Company (West Bromwich) Limited. The business was founded by Mr.

Alfred Turner, JP. and the late Mr. W. H. Smith. The

company produced good quality grey iron castings for the

motor, electrical and engineering trades and special

types of foundry plant that were used throughout the

world.

Since 1945 scores of Acme Vertical

continuous stoves for the foundry industry have been

exported to Australia, New Zealand, India, South Africa,

Canada, Sweden, Switzerland and Denmark.

The firm had a loyal team of

employees, the majority of whom were in its service for

over twenty years. Several employees brought their sons

into the business, and on the management side, Messrs.

A. E. R. Turner, Jnr., S. M. Turner and E. N. Smith were

actively engaged in the business for many years and

joined the Board of Directors.

The firm gained a high reputation

for customer service which resulted in large numbers of

"repeat" orders.

An ACME oil-fired 5 loop stove for

motor engine casting cores.

The firm went into

liquidation in 1990:

| The Foundry

and Engineering Company (West

Bromwich) Limited

Notice is hereby given that the Creditors of the

above-named

Company are required on or before 31st May 1990, to send

in their

names and addresses, with particulars of their debts or

claims, and

the

names

and

addresses

of

their Solicitors

(if any), to

the

undersigned John David Travers, of Haines Watts,

Sterling House,

71 Francis Road, Edgbaston, Birmingham B16 8SP, the

Liquidator

of the said Company and, if so required by notice in

writing by the

said Liquidator, are by their Solicitors or personally

to come in and

prove their said debts or claims at such time and place

as shall be

specified in such notice, or in default thereof they

will be excluded

from the benefit of any distribution made before such

debts are

proved.

J. D. Travers,

Liquidator

NOTE.

This notice is purely formal and

all known Creditors have

been or will be paid in full.

London Gazette

1st May

1990.

|

|

|

|

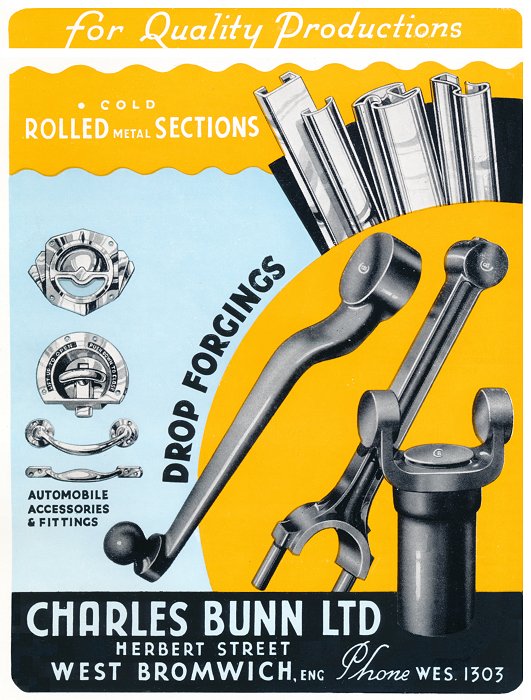

An advert from the mid 1950s. |

|

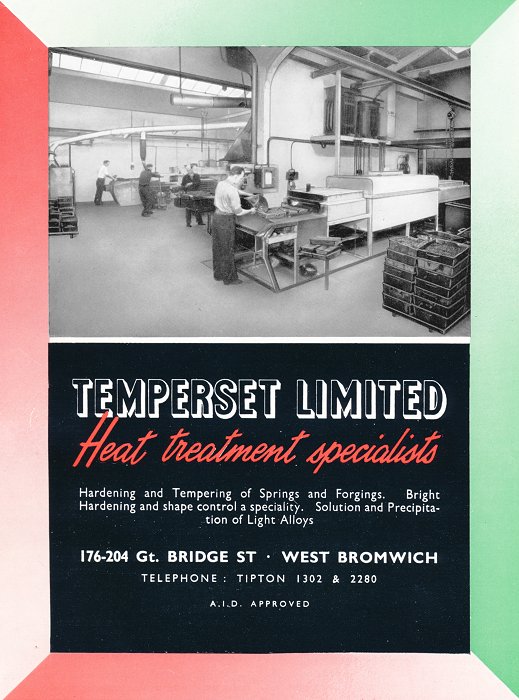

An advert from the mid 1950s. |

|

|

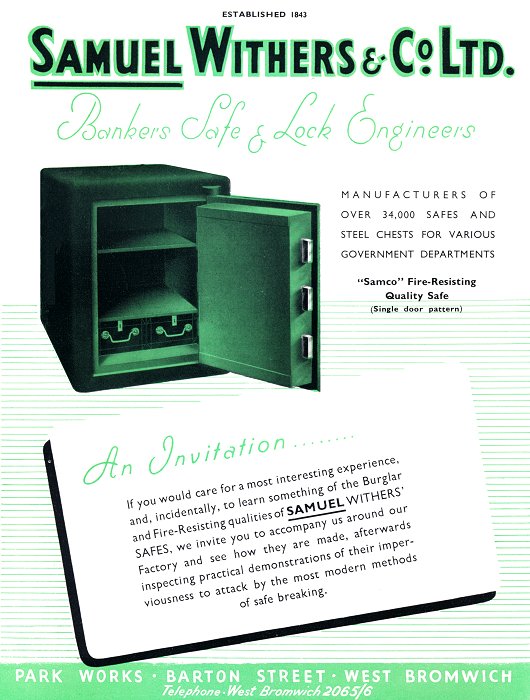

An advert from the mid 1950s. |

|

|

|

|

Return to

1861 Directory |

Return to

the contents |

Proceed to the

20th Century |

|