|

The Electric Construction

Corporation

When the new Corporation was formed, it purchased

and amalgamated the following companies and their patents:

| 1).

|

Elwell-Parker, Limited. Employing 400 people with

a large order-book. |

|

2). |

The Electrical Power Storage Company Limited, and

their Millwall factory, together with the company's many

electrical power storage patents. |

|

3). |

The Railway Electrical Contractors Limited, and

their patents and contracts for train lighting. |

|

4). |

The Julien Patents for Electric Traction, the

Sprague Patents for Electrical Traction and the Transmission of

Power. |

The starting Capital of the Corporation was

£500,000 in 50,000 shares of £10 each. Numbers 1 to 100 inclusive

were Founder’s Shares. The new concern was incorporated on 7th

June, 1889, and it was decided to build a new works on the land

already purchased by Elwell-Parker at Bushbury, along with some

adjacent land. The new works were erected at a cost of £10,000 on

the 24.5 acre site. When the building work was complete, the staff

and machinery from Commercial Road were moved to the new site. On

16th June, 1890 the Commercial Road factory was sold to the Electric

Construction Corporation. Presumably the E.C.C. continued to use the

works for some time, as the factory remained in the company's

ownership until 12th March, 1895 when the buildings were sold to

Thomas Brotherton and Francis Simms.

A description of the new works appeared in the Midland

Counties Express, on Saturday, 9th August, 1890, part of

which is as follows: |

|

The Electrical Works at Bushbury

Elwell-Parker machinery can be found in

every civilised country in the world, specially adapted to the

requirements of the transmission of power and electro-chemical

purposes. Elwell-Parker Limited is now part of a syndicate

called the Electric Construction Corporation. The business of

the firm recently assumed such immense proportions that it was

found necessary to acquire more commodious premises in which to

carry out the work of the concern.

Land was acquired in Showell Road,

Bushbury, and a new factory was built there. It is due to be

completed next month and will employ a large number of people.

There is one man above all others to whom the credit must be

given for introducing and developing this trade, and raising

Wolverhampton to a position of importance in the commercial

world, which this town would otherwise not have attained, but

for his skill and enterprise, and it is to Mr. Thomas Parker. |

|

It was resolved in 1887 to erect new premises in

Bushbury, and a portion of the land was purchased for that purpose,

however, when the concern was taken over by the present company, the

Electric Construction Corporation, Limited, it was resolved to build

on the site first proposed but on a larger scale. Employment is

found in the present works for about 600 hands. Large orders are in

hand, and work assured which will fully occupy the new works, and it

is expected that 2,000 hands will soon be employed. In this concern

Mr. Parker holds the position of chief engineer and works director.

Honours have also been thrust upon him. In 1885 he was made a member

of the Institution of Electrical Engineers, and in 1889 a member of

the Institute of Civil Engineers. |

|

At the new works the machinery is bolted down

into the concrete foundation and upper columns carrying the roof

trusses have a specially designed head, which allows the

rainwater from the roof to flow down the columns to a drain at

the bottom. A siding from the L.N.W.R. is brought into the

works, and runs across the shops at the top end, so that the

electric overhead travelling cranes can deposit goods upon the

trucks for removal from one shop to another, or for sending them

away. There will be two 10 ton travelling cranes in a 45 ft. bay

and two identical ones in the foundry. The remaining five bays

of the main shop are fitted with 5 ton cranes worked in the same

way. The siding is also taken to the foundry cupolas and boiler

house. The office windows overlook the shops and yard and there

is an enquiry and a timekeeper’s office in-between the workmen’s

entrance and the main entrance, so that the timekeeper can see

everyone who enters or leaves the premises. There are two

waiting rooms for the offices, one for the works, and a

consulting room adjoining Mr. Parker’s office. There are three

large offices for the secretary, electrician and chief

draughtsman. There is a strong room lined with fire brick and

fitted with Chubbs’ patent fire and thief-proof door, which

opens from the secretary’s office.

There is a large board room, telephone room,

storeroom and typewriter room close to the clerk’s desk. There

is a photographic room for copying drawings, a pupil’s room,

which is entered from the works, separate lavatories, a cloak

room and a clerk’s dining room. The drawing office and clerk’s

office are each 32ft. by 34ft. 6 inches and are partly lit from

the roof. There is a corridor leading from the clerk’s office to

the works so that instructions can be given to workmen and

enquiries for drawings etc. can be made without disturbing the

main office. A covered passage also leads from the offices to

the warehouse. The engine house, which is 35ft. square and the

boiler house, which is 78ft. by 45ft are built on the east side

of the main shops.

The boiler house is 7ft. 9 inches below the

level of the main yard and contains seven Babcock and Wilcox

boilers. Projecting from this and under the yard are coal

bunkers with a siding passing over them so that coal can

immediately be shot-down to the level of the boilers. The

circular chimney stack is 120ft. high and 8ft. internal diameter

at the bottom, tapering to 6ft. 8 inches internal diameter at

the top, with a large moulded cast-iron cap. The laboratory, on

the left-hand side of the gateway into Showell Road measures

56ft. 6 inches by 20ft. and consists of chemical and physical

departments, separated by a glass screen. There is a small 20ft.

by 10ft. room which is used for rough work and the storage of

batteries. The laboratory has a number of porcelain sinks,

specially designed tables and fume closets.

The pattern shop and storeroom each measure

100ft. by 33ft. 6 inches and extend along Showell Road, just

above the laboratory, and have suitable workbenches for the

construction of patterns. The iron foundry measures 160ft. by

82ft. 2 inches and the brass foundry measures 62ft. 2inches by

40ft. They stand on the opposite side of the siding to the

pattern shop and are similarly constructed to the large shops,

with columns, girders and cranes etc. and have temporary ends so

that they can be extended if required. Three large drying stoves

are provided with specially designed furnaces and there are two

of Thwaite’s patent rapid cupolas with a lift and charging

platform, each capable of melting 5 tons per hour.

The blacksmith’s shop, built alongside the

iron foundry measures 84ft. by 30ft. and is designed for 12

forges, and the latrines and water tower and tank are built

between the main shops and the foundry. The water tank is 20ft.

6 inches above the ground and holds 35,700 gallons. Water is

pumped into it from the brook, which runs through the site. It

will be used for supplying the boilers, sinks, lavatories etc.

The mess rooms consist of two large dining

rooms, one 70ft. by 40ft. for men and another 40ft. by 30ft. for

women. In between is a kitchen, measuring 25ft. 3 inches by

32ft. 3 inches. It is fitted throughout by the Coalbrookdale

Company, with a large range and grill, vegetable steamers, and a

hot closet so that workpeople can bring their own food and have

it warmed-up. There are lavatories on each side of the entrance

and each person will have his or her own place and number with a

coat-hook.

The site occupies about 24 acres, with yards

paved in tarmac covering about 4.25 acres. The bricks for the

general work came from the Tibbington brickworks, the blue

bricks came from Hockley Hall Company and the facing bricks for

the offices and mess rooms were supplied by Messrs. Partridge

and Company of Kingswinford.

Over the main entrance to the offices is an

ornamental clock tower, with stone dressings. The pilaster and

moulded pediment over the entrance doors, and all exterior

stonework are executed with white Hollington stone. The office

roofing tiles were obtained from the Hockley Hall Company and

the other roofing tiles are of best Bangor slate. A large

proportion of the roofing area is glazed on the simplex system

and the main shops are paved with patent granitic flooring. The

laboratory floor is made of wooden blocks set on a concrete

foundation and the office corridors are laid with Ebner’s

Terrazzo Mosaic with a coloured glazed brick dado with moulded

capping four feet high. Most offices are heated by open

fireplaces, but the large drawing and clerk’s offices are warmed

by hot water on a low pressure system, the boiler being placed

in the basement in a separate room. The mess rooms are also

heated on the same system. The large shops will be heated by the

exhaust steam from the engines, carried in 4 inch pipes between

the columns. |

|

|

An attempt was made to make Thomas Parker a

director of the new concern6,

but this was defeated and he had to be content with the post of

Works Manager.

The Corporation got off to an excellent start under the

chairmanship of Sir Henry Mance. The works were operating at

full capacity and orders flooded in, including a further order

from the Birmingham tramways, following the successful running

of the Elwell-Parker prototype. In the battery-powered vehicles,

the accumulators were placed under the passenger's seats, and a

portion of the gross profit was absorbed in the settlement of

claims from passengers, whose clothing had been splashed by

acid.

In 1890 two Elwell-Parker type dynamos were displayed at the

Paris Exhibition. They were driven by two Crossley 'Otto' gas

engines, and supplied power for lighting.

One of the dynamos sent to the Paris

Exhibition.

In 1890 another Elwell-Parker type dynamo was

displayed at the Edinburgh International Exhibition on the

Carrick and Ritchie stand. It was operated by a Carrick and

Ritchie 'Waverley' water turbine. The firm supplied the turbines

with the Elwell-Parker type dynamos for lighting installations

in large houses or factories.

Many of Thomas Parker's designs were ahead of

their time. In the 1880's a number of power stations were built

for electricity distribution. They all used D.C. because of the

difficulties involved in running A.C. generators (alternators),

in parallel. When a number of alternators are connected in

parallel, each one must be synchronised to the others, so that

all of the outputs are in phase. This was first achieved

experimentally by Dr. Hopkinson in 1886, but was not put into

practice until 1891. This is an essential requirement for modern

electricity distribution. The first two installations using this

technique were at Bournemouth, using Mordey alternators and at

West Brompton using Parker machines. Another year passed before

A.C. generation came into general use.

In 1890 the E.C.C.

granted a licence to the General Electric Power and

Traction Company of Kentish Town, London for the use of its

traction patents. The firm also agreed to supply the traction

company with accumulators. By 1893 Thomas Parker was a director

of the traction company.

|

| |

|

| Read about phosphorus

production and Heath Town works |

|

| |

|

|

E.C.C. also developed an overhead-wire, tram

system, which was put to use in 1893 when the company

electrified the South Staffordshire Tramways and a little

while later the Hartlepool tramway. Thomas Parker laid-down

a section of tram-line at the works, which he hoped would be

largely copied in London for direct tram-driving. |

| |

|

| Read about the South Staffordshire

Tramways |

|

| |

|

|

The E.C.C. received another order for an 800 ampere-hour battery, for the

Whitehall Court in London, followed by possibly the most important order

at the time, for the electrification of the Liverpool Overhead Railway.

This was the earliest and only example of an elevated electric

railway in the country. The project was a great success, and in

1900 the company undertook the re-electrification of the City

and London Railway.

Read about the

Liverpool

Overhead Railway |

|

Another important order was the planning and installation of

the Oxford Electric Company's Works, which was so successful

that it became known as "The Oxford System" of electrical

transmission. The E.C.C. specialised in direct current high

tension, and their "Oxford System" included a central generating

station, supplying 2,000 volts D.C. into sub-stations, where

motor-generators stepped the voltage down to 200 volts. The same

system using a central supply of 1,000 volts was used at

Birmingham, Charing Cross, Chelsea, Sydenham and Shoreditch. The

company also installed the electricity generation and

transmission system for lighting at Burnley.

|

The

Crystal Palace Electrical Exhibition. The Engineer, 1st

April, 1892.

The present exhibition at the Crystal

Palace will mark the successful operation of one of the most

practical modern schemes for the distribution of electric

current over wide areas. The continuous current transformer

has here asserted itself, and proved that with carefully

worked out details in construction, and in the system with

which it is used, it is a most trustworthy and

efficient means of securing the advantages of a high tension

distribution with a continuous current supply. No

undertakers who find themselves called upon to extend their

low tension mains into remote suburban districts need fear

that because they do not happen to be using alternating

currents, they must either bear the cost of additional

stations to feed the network or sink excessive amounts in

mains.

The entire system has been worked out

on a practical basis by the Electric Construction

Corporation of Wolverhampton under the guidance of Mr.

Thomas Parker, the works director, and one of the most

pleasing exhibits in the exhibition is to be found in the

stand of this Corporation in the Machinery Court, containing

as it does machines of such high-class construction, and

controlling apparatus so well suited to the requirements of

the system.

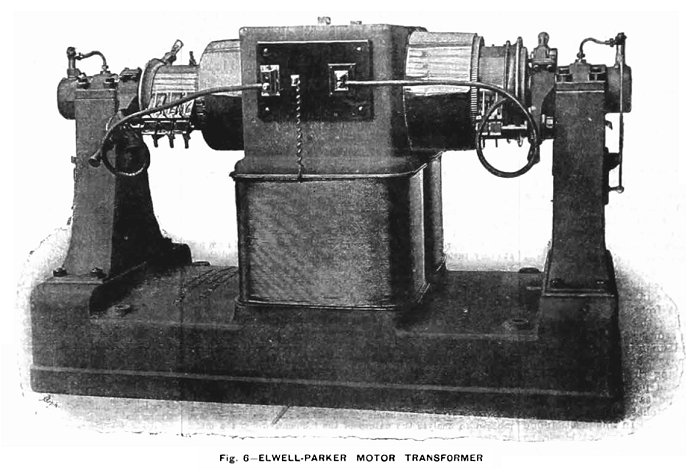

The largest machine in this stand, Fig.

6, is a continuous current transformer or motor transformer,

identical in size and output with the ten machines used

inside the Palace for the supply of current to exhibitors.

It is to be regretted that it was found necessary to fix

these machines so far out of sight underneath the Palace, as

otherwise their full display in operation would have

considerably added to the practical interest of the

exhibition.

We have already explained the working

of the machines in the Palace, which receive current at

1,000 volts pressure from the Crystal Palace and District

Electric Supply Company’s Station at Sydenham, one and a

quarter miles distant, and transform it down to a pressure

of 110 volts for exhibitors. The complete system of

distribution by these motor transformers for town lighting,

as now adopted at Oxford, will be understood by reference to

Fig. 7.

In the first place there is the

generating station, the site of which is selected with

reference to good water supply and economical facilities for

delivery of coal. In this station are installed the

necessary engines and boilers, together with the electric

generators and their exciters. As the area of lighting

extends, more generators can be added, their manipulations

in parallel being perfectly simple. These produce current at

1,000 volts pressure, which is delivered by all the machines

on to one pair of bars in the station, known as omnibus

bars, or shorter, bus bars. From these the current proceeds

along the high tension mains to the most central point in

the district of supply, at which is located a central switch

station.

From this station is controlled the

working of all the transformers used in the system, these

machines being located in sub-stations situated radially

around the switch station at points most favourable for

feeding the low tension network of supply, and keeping the

electric pressure uniform throughout. At the switch station

there is a pair of omnibus bars receiving the high tension

current from the generating station, and from which the same

current is, through double pole switches, connected onto the

feeders supplying the motor transformers at the

sub-stations. For the complete control of all the

transformers only one man is required in the switch station.

The voltmeters in this station show the

pressure on the town supply network at all the sub-stations,

and as the load increases in any district, the pressure is

kept up by switching on an additional transformer located in

that district. Although the sub-stations where the

transformers are fixed are at various distances away from

the switch station, the switching in or out of these

machines controlled by one man at the above station with

perfect certainty and ease.

In performing this operation the first

thing to do is to close the two-pole switch which conveys

the high-tension current to the transformer. The current,

which passes through a considerable resistance before

leaving the station, passes into the armature of the machine

on the high-tension side, and excites the field through a

few turns of thick wire in series. The brushes on both

commutators are kept permanently down, and need no

alteration of lead for changes of load, as the reactions of

the two armatures neutralise one another. Once the

excitation of field is started, the machine starts, at first

quickly, but the shunt field rapidly building up, the speed

soon decreases again, and is then brought up to the required

amount by reducing the main resistance in the switch

station. So far the transformer is started, but the

secondary winding on the armature is not yet put in

connection to feed the supply mains. This is done at the

switch station by the simple act of momentarily closing and

opening a switch which short-circuits the voltmeter. This

causes a current to flow through an automatic circuit closer

fixed with each transformer in the sub-station.

This apparatus, shown in the figure,

consists primarily of an iron-clad electromagnet, the

exciting coil of which is included in the circuit of the

voltmeter at the switch station. The resistance being small

does not interfere with the voltmeter readings, and,

moreover, by short circuiting the voltmeter in the switch

station for an instant, a large current from the supply

mains flows through the coil, causing the armature of the

magnet to be drawn up. The armature carries two pawls lying

on a ratchet wheel, and upon its being attracted upwards,

the left-hand pawl engages one tooth and moves the ratchet.

Again, on breaking the short-circuit

the armature falls, and the right-hand pawl engages, forcing

the wheel round further in the same direction. The double

operation moves the ratchet wheel and cam through one-eighth

of a revolution. In this position one tooth of the cam bears

down on the contact block, so completing the low tension

circuit from the transformer to the mains. The load on the

mains is equally divided between the transformers at work,

but in case of short circuit or any accidental stoppage

which would cause an undue rush of current into the machine,

an automatic cut-out, shown at M is fixed in connection with

the above apparatus. The armature of the electromagnet M

would in such an event be drawn up and strike the cam,

shifting it round and disengaging the tooth from the contact

piece S, thus breaking the circuit.

Similarly, as the load decreases, the

various transformers can be severally disconnected from the

supply by the operator at the switching station. Once

closing and opening the voltmeter switch shifts the cam

another eighth round, and allows the contact piece S to rise

and break circuit.

|

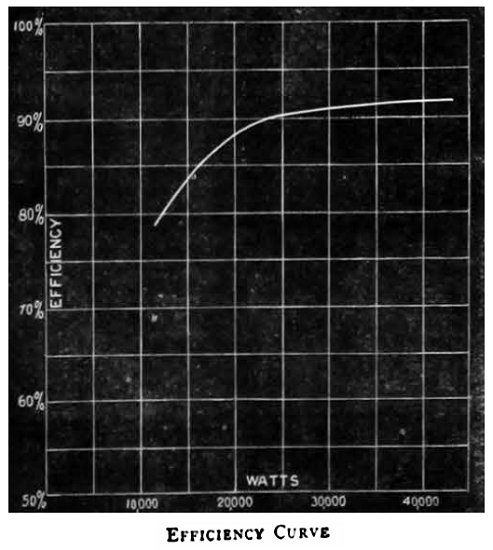

By this arrangement the transformers are only

used as the load requires, and are therefore, for

the greater part of the working time, near their

full load; and as the efficiency of these machines

reaches 92 percent when delivering their full load

of 40 kilowatts, and 87 percent at half load, see

curve, Fig. 8, it will be seen that the whole system

is worked with great economy. The only regulation

required in the generating station is the adjustment

of the strength of exciting current supplied to the

generators, the pressure, as indicated by a

voltmeter on the omnibus bars in the station, being

maintained constant by this means. The exciting

current is regulated by resistance in the shunt

field of the excitors, of which there is a separate

machine for each generator. |

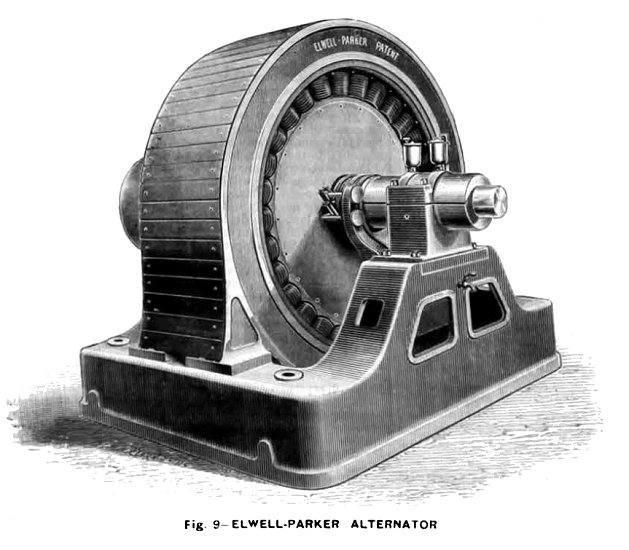

The Corporation have also carried out

several important contracts in alternating current plant. We

illustrate the Elwell -Parker alternator, Fig. 9, of 80

kilowatts, as exhibited in operation at the Palace. The

armature is a stationary external ring, built up of soft

iron rings, to the inside surface of which are clamped the

coils. The latter are twelve in number and composed of

copper strip, the edges being placed radial to the machine.

These are held by wooden clamps bolted round the ring on

each side. The field magnet, with the same number of coils,

mounted on cores and yoke of solid forged iron, rotates

inside the armature. The machine being high-tension, the

armature is externally cased-in with a wooden cover, and the

terminals of the machine are protected under a portion of

this cover, kept under lock and key. The wires leading from

these terminals are also taken underneath the bed of the

machine in casing through the concrete, so that complete

immunity from danger is attained.

Alternate current transformers of 2 and

4 horse power output are also shown in Fig. 10. These are of

very simple construction, the two circuits being first bound

together and afterwards encased around with soft iron plates

made in the form of the letter L and built up on each side

of the coils. The two rows of discs are then clamped

together by bolts passing through cast iron end pieces.

The Corporation also exhibit a new

pattern of adjustable resistance, sets of cut-outs fitted in

porcelain boxes, and a high tension automatic switch used in

connection with the above transformers. |

|

|

Electric Lighting in Oxford. The

Engineer, 1st July, 1892.

On Saturday, June 18th, the electric

current was switched on for the first time to the City of

Oxford, by the Oxford Electric Company, and a large party

had been invited to a dinner given at the works in honour of

the occasion. The arrangements were very satisfactorily made

by Mr. George Offor, the secretary of the company. We have

referred previously in our issue of April 1st last to some

of the features of the system employed, and are now able to

give a full description of the plant.

It was found impossible to obtain a

suitable piece of ground for the works near the centre of

the city, a piece of land was therefore acquired at Osney

upon the banks of the River Isis.

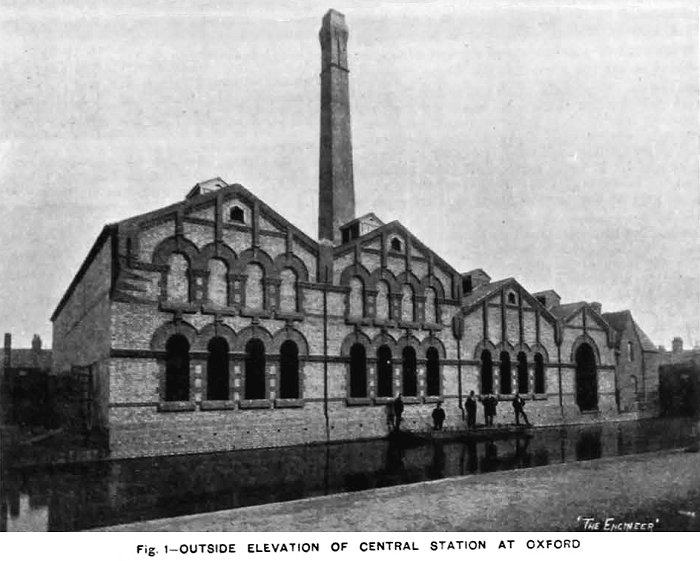

The outside of the building, which are

of a neat design in brick, is shown in Fig. 1. The interior

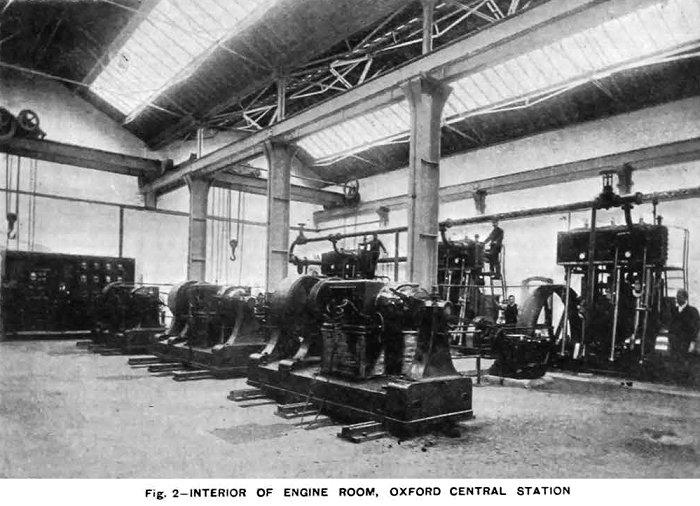

of the engine room is shown in Fig. 2, from which it is

evident that there is ample room for more plant. This

position will enable the company to charge electric

launches, which will be an important source of revenue, and

the works are kept away from the better parts the town.

The

system adopted is that of high-tension continuous currents,

with dynamotors or current transformers, which produce

currents of low pressure for the network. The dynamos at the

generating station produce the current at a pressure of

1,000 volts, and this is transformed down at the sub

stations to a pressure of 100 volts. Fig. 3 is a plan of the

part of the city in which the substations are placed, and

the mains already laid along the streets are shown.

The

contractors for the whole work are the Electric Construction

Corporation, of Wolverhampton, and it has been carried out

under the supervision of Mr. Thomas Parker, the managing

director. The building is a well built structure of brick,

designed by Mr. Brevitt, of Wolverhampton, and the builders

were Messrs. Kingerley, of Oxford.

It is divided into two main sheds,

separated by a brick wall. The engines and dynamos are

placed in one part, and the boilers in the other, and all

the plant is on the ground level. The engine room is thus

kept perfectly free from coal dust. Three steel boilers of

the locomotive type are at present installed; these were all

built by Messrs. J. and H. McLaren, of Leeds; a Green's fuel

economiser is placed in the main flue and a suitable by pass

is arranged so that gases may pass direct to the chimney if

needful.

The engine room is well lighted from

above. The steam pipes are arranged upon the ring system, so

that in case of breakdown, as little as possible of the

plant would be affected. Stop valves are placed between each

two engines, and the bends are all of copper. Three engines

are now put down, and these are of the inverted

triple-expansion type, built by Messrs. J. and H. McLaron

and Co. By the courtesy of the makers we are enabled to give

the results of tests which were carried out at the works by

Mr. Wilson Hartnell, Professor Goodman, and the inspecting

engineer, Mr. Watson. The sizes of the cylinders are:-

high-pressure, 9in. diameter, intermediate, 14·25in.,

low-pressure 22·5in. diameter, by 24in. stroke.

Two trials

were made, in one of which it will be observed the steam

jackets were used, an in the other were not used. We may add

that the high-pressure and intermediate cylinders are jacketted with steam at boiler pressure, and are drained

through a McDougal steam trap into the hot well. The

low-pressure cylinder is not jacketted. The McLaren

automatic governor is placed inside the fly-wheel upon the

shaft itself, and it works direct on to the high-pressure

slide valve, which is not balanced in any way. The governor

is self-locking, and is therefore not affected by any

friction on the slide valve. The engines run very steadily,

and all danger of the governor being put out of gear by the

breaking of a belt is obviated. The surface condenser

is fitted with brass tubes and tube plate; the tubes are

⅞in. outside diameter, and there is 382 square feet of

cooling surface.

The air pump is 11½in. diameter, the

circulating pump 10in. diameter, and the feed pump 1¾in.

diameter, all three having a stroke of 14in. The pumps are placed behind the

condenser, and are worked by levers from the intermediate

engine. The crank shaft is of forged steel, 5¼in. diameter,

the crank pins 5½in. diameter, and the engines are

thoroughly well finished. Each of the engines is provided

with a heavy fly-wheel, and drives a dynamo by means of

belting; two of the belts are of the usual double-sewn type,

and the third is a Gaskin link belt.

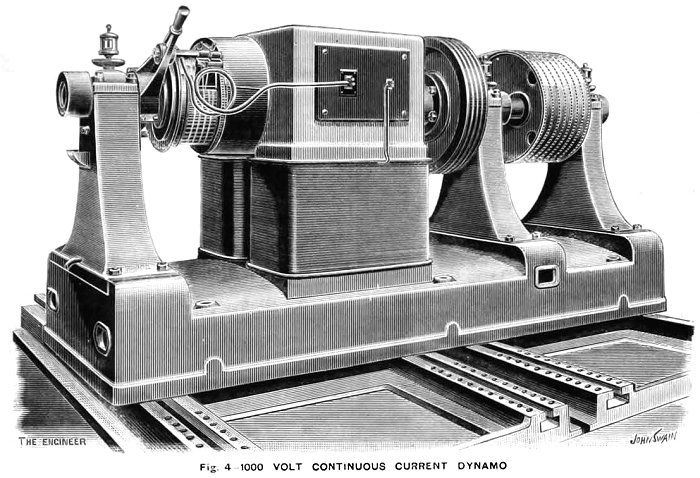

The three dynamos, one of which is

shown in Fig. 4 are all similar, and were built by the

Electric Construction Corporation; each develops 1,080 volts

and 80 amperes, when running at 400 revolutions per minute.

The dynamos are provided with an extra bearing outside the

driving pulley, and each is excited by a small Elwell-Parker

dynamo, driven from a rope pulley keyed on to the shaft of

the main generator. The exciters give 135 volts, and can

thus be used to charge the accumulators which are used for

lighting the central station.

The electro-motive force of the dynamos

can be regulated from 1,100 volts at full load to 1,000

volts at light load, by means of resistances placed in

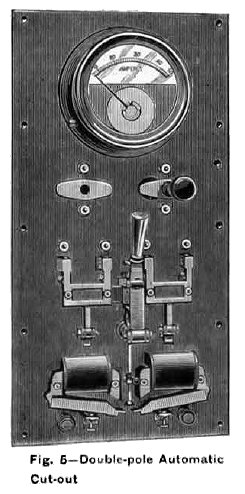

circuit with the exciters. In the circuit of each dynamo is placed

a double pole automatic cut-out, shown in Fig. 5 which

protects the dynamo in the event of any excessive current,

and is reset by hand, but it is so arranged that the cut-out

cannot be held on. The dynamos are all connected in parallel

to two common omnibus bars upon a switchboard at the works.

The foundations for the engines are of

a solid block of concrete, and that for the dynamos another

solid block, weighing about 100 tons each, and about 11ft.

deep. Air spaces are left round the blocks to diminish

vibration.

The switchboard at the works is very

simple, and consists of three panels, each of which is

similar to Fig. 5, and carries one ammeter for the high

tension circuit, one for the exciter circuit and the

knocking-off switch previously alluded to.

|

Two overhead cranes, each capable of

lifting six tons, are provided in the engine house, and a

battery of fifty three E.P.S. cells is used for the lighting

of the station. By means of this battery and of that at the

chief sub-station, it is possible to shut down altogether at

the works for six to eight hours in winter, and twelve to

sixteen hours in summer. At the time of our visit, Mr.

McLean, the engineer in charge, had placed a dynamotor in

the works in order to light up about five arc lamps of

fifteen amperes each, and 370 eight candle-power lamps.

Current was also supplied for the electric cooking, which

formed a feature of the dinner.

From the generating station run out two

pairs of heavily insulated Silvertown cables, each

consisting of 37/14 copper wires; these are laid in

cast iron pipes, and are carried a distance of about

one mile to the distributing station at Broad Street

marked No.1 on the plan, Fig. 3.

The system of working is clearly shown in

diagram-Fig. 6 which we published in a previous

issue. It will be seen that the dynamos are coupled

to two omnibus bars at the generating station, and

thence run the high-tension mains to the central

switch station, whence all the other sub-stations

are controlled. |

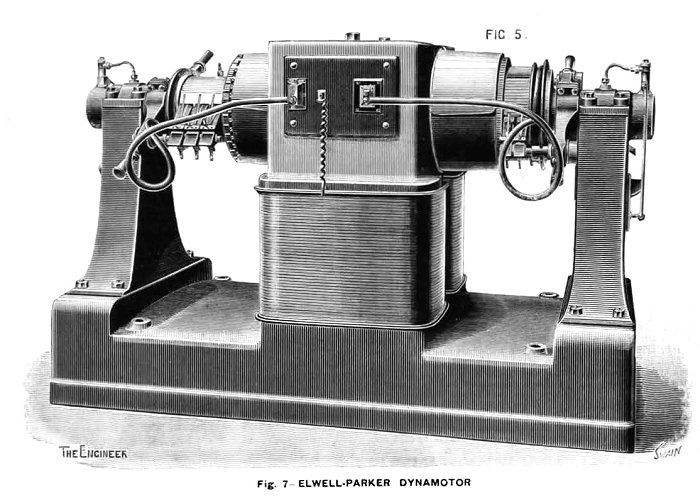

At each of the

stations, Nos. 1, 2, and 3 on the plan Fig. 3, is placed a

dynamotor, such as shown in Fig. 7, which transforms the

pressure from 1,000 volts to 110 volts, and gives out a

current of 360 amperes when fully loaded. The efficiency of

these machines is very high, being 92 percent when fully

loaded, 89 percent at three quarters load, and 87 percent at

half load. The main winding is a shunt to the low-tension

side, and there are a few turns on the magnets in series

with the high-tension armature. The oiling arrangements are

very complete. The end of the armature shaft is provided

with a cam, which actuates the piston of a small oil pump

which feeds the bearing; the oil passes away through a

filter to the oil reservoir, and is used over again. It is

thus possible to run for some days without attention. The

brushes upon the commutator are of copper gauze.

An accumulator of 114 cells of the L.

31 E.P.S. type is installed here, and the cells are arranged

in four groups, two of thirty-eight cells and two of

nineteen cells. They are charged in three groups of

thirty-eight cells each, and are discharged in two groups,

each consisting of thirty-eight and nineteen cells in

series, and are capable of supplying a current of 120

amperes for eight hours.

|

Voltmeters are provided at the central

switch station, which show the pressure at each of the

sub-stations, and all the transformers can be controlled by

one man. In starting a transformer the high-tension circuit

is first closed through a resistance in order not to injure

the armature windings.

The dynamo field is then excited by a

few coils in series. The dynamo part then begins to produce

current, and the resistance is gradually taken out of the

high-tension circuit.

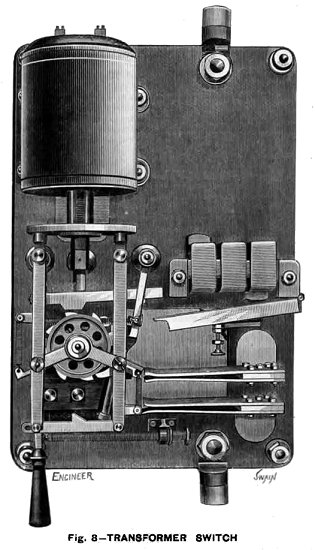

In order to put the transformer into

circuit with the low pressure network, a special apparatus

has been designed, shown in the diagram and also in Fig. 8;

this instrument is placed at the sub-station and is designed

for 400 amperes.

It consists of a long-pull electro-magnet,

which actuates a ratchet wheel and controls the switch. It

is actuated by merely closing and opening a switch which

short circuits the voltmeter on the pilot wire. One of the

wires to the voltmeter is wound round the long-pull magnet,

and the feeble current passing to the voltmeter under

ordinary conditions is not sufficient to attract the

armature, but by closing the switch the voltmeter is cut out

of the circuit, and the long-pull magnet acts; the switch is

then opened, the heavy armature drops, and the double

movement causes the switch which connects the low-tension

network to the transformer to close. In cases of accidental

overloading, an automatic cut out-shown in Fig. 5 opens the

circuit.

|

|

The present capacity of the entire

plant is 12,000 lamps of 32 watts, and 15,000 lamps could be

wired. The low-tension mains were manufactured and laid by

Callender's Bitumen Telegraph Company, under the

superintendence of their engineer, Mr. W. Douglas Reid.

Those cables are of two sizes, half a square inch and a

quarter of a square inch section, and are of the

lead-sheathed type, armoured with two layers of steel tape.

These cables are simply laid in a trench under the footway,

at a depth of about 18in. They are laid in lengths of from

150 to 200 yards, and are connected together in cast iron

joint-boxes by means of copper connectors. The box is then

run in solid with bitumenised wax compound. Disconnecting

branch boxes are provided at different points in the network, so

that any section or street can be cut out without in any way

interrupting the supply to the rest of the network.

House service wires are connected in T

boxes by means of T copper connectors. These boxes and

connectors are so made that the cable is not out, but is

simply bared down to the copper strands and the connector

put on and soldered. The box is then run in solid with the

bitumenised wax compound. The small service wires are of two

sizes, seven fourteenths and twelve fourteenths, lead

sheathed and armoured. The arc cables are similar, but seven

sixteenths. The whole installation is a very interesting

example of the possibility of using high-tension continuous

currents for large areas.

|

|

High Tension Continuous Current Switchgear. The Electric

Construction Corporation, Wolverhampton. The Engineer 31st

March, 1893.

|

The switchgear illustrated by the

accompanying engravings are those used by the Electric

Construction Corporation, Wolverhampton, for their high

tension continuous supply system, as used at Oxford, and at

Sydenham.

The system consists in supplying a

system of distributing mains with current from a number of

motor generators situated at sub-stations, these being

supplied with current by high tension feeders run directly

from switchboards at a central station. Each transformer has

a separate feeder, and a pair of pilot wires also come back

from each sub-station. The starting, stopping, and

controlling of the motor generators is carried out from the

central station.

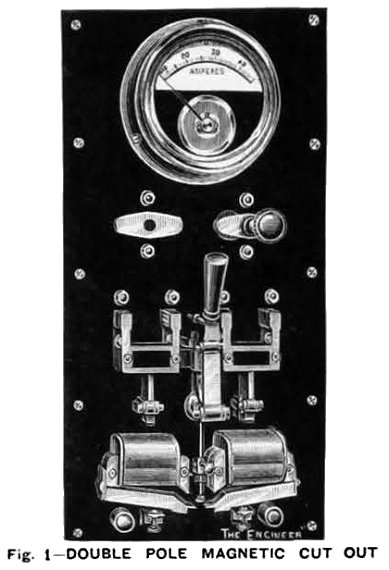

Fig. 1 represents a double-pole

automatic magnetic cut-out and main switch, which is coupled

on to the main omnibus bars at the central station, and from

which feeders running between the transformers are

connected.

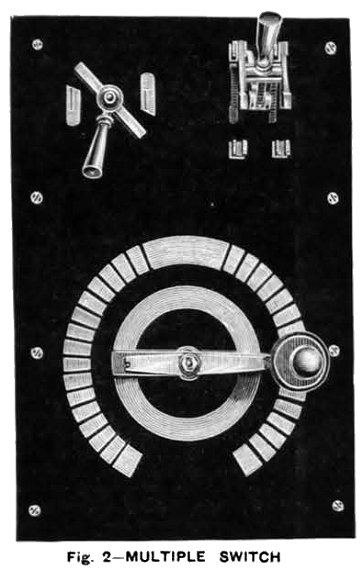

Fig. 2 represents a multiple contact

switch for cutting resistance in or out of the high-tension

feeder circuit. To start a transformer the multiple-contact

switch - Fig. 2 - is turned over, so that all resistance is

in circuit. The automatic cut-out- Fig. 1 - is then put on

so that the high tension current passes to the motor

generator at the sub-station. |

|

|

A few turns of thick wire wound round

the magnets in series with the feeders gives the necessary

magnetic field, enabling the motor generator to start. The

secondary or low tension then gradually magnetises the motor

generator field up to its full strength by a shunt across

the low-tension armature.

The starting resistance, which is

connected to the right-hand side blocks of the multiple

contact switch, Fig. 2 - is then taken out of circuit. The

small quick-break switch, shown at the top left hand corner

-Fig. 2 - is then closed, which short circuits the pilot

wires running back from sub-station, and one of these, wound

round a pot magnet, actuates a special transformer switch,

which connects the low-tension armature of the motor

generator on to the distributing mains. This switch is then

again broken, as only a momentary current is necessary, the

switch being held in either an on or off position by

springs.

A voltmeter is connected across the

pilot wires so as to indicate the electro-motive force on

the network at the feeding point. The regulation of this

electro-motive force is carried out by the left-hand blocks

of the multiple-contact switch - Fig. 2 - cutting resistance

in or out of the circuit. |

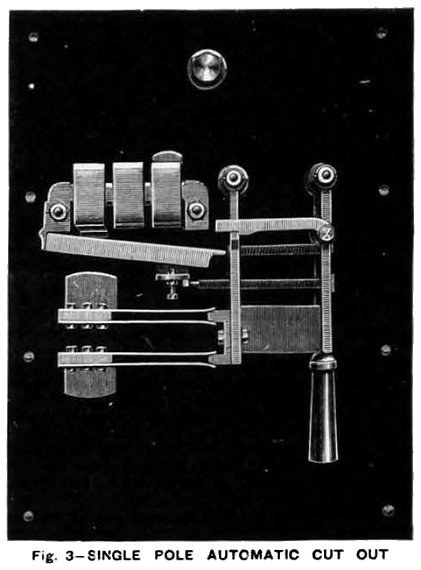

| Fig. 3 represents a single-pole automatic magnetic

cut-out, as is used at Oxford on the low tension of

transformers, situated at the central station, where they

can be reset by hand.

These cut-outs break circuit in event of an excessive

current being demanded by a short circuit on the mains.

The magnet is compound-wound, so that in the event of one

of the motor generators failing to give proper

electro-motive force, the current passing back from the

mains cuts out at a much smaller number of amperes, so as

not to cause an excessive demand from any other motor

generators that may be on the circuit, which is a thing that

always happens where ordinary fuses are employed; any fault

due to one machine failing to give its electro-motive force

usually melting the fuses of other machines that may be

connected in parallel on to the same circuit, owing to the

large current required to cut out the machine that has

failed. |

|

|

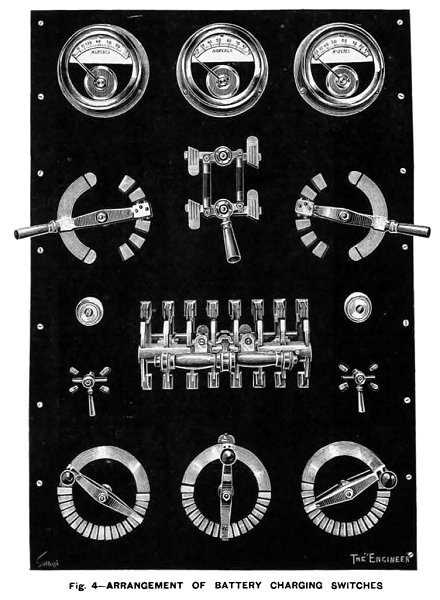

Fig. 4 represents an arrangement for charging a battery

of accumulators from distributing mains. As these are kept

at a constant electro-motive force, it is necessary to

cut-up the battery into sections for charging. At Oxford

there are 120 cells. These are charge in sets of 40 each,

discharging in sets of 60 each. A throw-over switch in the

centre of the board enables this alteration to be effected.

Three multiple contact switches at the bottom of the board,

and three ammeters at the top, are connected, one in each of

the three series when charging.

Two multiple contact switches enable the number of cells

in the discharging circuit to be regulated, and a

double-pole switch is provided for cutting off the

accumulators entirely. The two-way switches are provided for

connecting the voltmeter across one or other of the

batteries. |

|

|

| Read about some of Thomas

Parker's railway locomotives |

|

Within four years the new company found itself in deep trouble

and was voluntarily wound up in July, 1893. It seems that there

was a lot of dissension amongst the Board of Directors, one of

whom was later convicted of fraud. It was immediately

reconstituted as the Electric Construction Company under the

chairmanship of Sir Daniel Cooper.

|

The E.C.C. works in about 1902.

|

The Financial Times of 6th

July, 1893 mentions that the debenture holders and shareholders

agreed to reconstruct the Electric Construction Corporation into

the Electric Construction Company. The capital will be

written-down from £879,260 to £650,000 as the assets are now

considered to be less than was previously stated. The ordinary

shareholders will receive two £2 fully paid shares in the new

company for each fully-paid £10 share in the old Corporation.

Preference shareholders will receive five fully paid, seven

percent, cumulative preference shares of £2 each (£10), for each

£10 fully-paid seven percent cumulative preference share, of the

Corporation. Holders of Founder’s shares are to receive two £2

fully paid ordinary shares in the new company, for each £10

Founder’s share in the Corporation. It will be seen that the

heaviest loss falls on the ordinary shareholders, but the

apparent loss of capital makes no real difference, because the

£10 shares are barely re-saleable at 30s.

| The E.C.C. dynamo

at Cragside.

It is pure Thomas Parker,

looking just like an Elwell-Parker product.

Courtesy of Robin Wright,

Engineering Warden, Cragside. |

|

The Electrical Power Storage Company, one of

the founder members of the Corporation was originally purchased

for £150,000 and later sold to the Foreign and Colonial Power

Storage Company for £75,000 in shares.

Sir Daniel Cooper was greatly disliked by Thomas Parker and

five of his senior staff from Elwell-Parker. They all resigned

within a year of Cooper's chairmanship, and at the first A.G.M.

in September, he referred to Thomas Parker in such a way that

suggested that there was no love lost between them. Thomas

Parker himself referred to the directors as "all that coterie,

about whom the less said the better".

Read about the

presentations

made to Thomas's senior

staff on their departure from

the E.E.C. |

|

The Express & Star newspaper of 11th April, 1894, contains an

article about Thomas Parker's resignation from E.C.C. It

includes the following paragraph:

We understand that a new company will be promoted with Mr.

Parker as one of its members, for the carrying out of works of a

similar character in this district, which will be of such

dimensions as will add considerably to the manufacturing

interest of the neighbourhood.

Thomas's resignation was also reported in the May 1894 edition of

The Railway Engineer as follows:

Mr. Thomas Parker, M.Inst.C.E., who designed and carried out

the electrical plant and motors of the Liverpool Overhead Railway,

has resigned his position as works director to the Electrical

Construction Company, Ltd. Mr. Parker had entire charge of the works

at Wolverhampton since the formation of the Electrical Construction

Company. He has registered a new Company - Thomas Parker, Limited,

and has secured a very fine site for his works at Wolverhampton. We

are informed that Mr. A. B. Blackburn, M.lnst.C.E.

(lately with Messrs. Mather and Platt Ltd.), has been appointed to

the position vacated by Mr. Parker.

|

|

|

|

|

|

Return to

the 1890s |

|

Return to the beginning |

|

Proceed to the

General Election |

|

|