Dudley had a wide variety of industries, thanks to the

building of the canal network in the late 18th century

and a plentiful supply of raw materials in the form of

coal, iron ore, limestone and fireclay. As the

industries grew, the landscape became dominated by pit

heads, chimneys and glass cones.

The

area was ideally situated for the many industries that

appeared, because of its location in the central part of

the country and the excellent transport links in the

form of canals, followed by the railways and the

improved road network.

The

industries were extremely successful until modern times,

when most disappeared because of competition from cheap

foreign imports.

|

|

John

Barnsley and Sons Limited

The Barnsley family were

originally farmers who opened an iron foundry in

1809. They specialised in lifting tackle for

builders and structural engineers and were also

world famous for making Jews Harps, which at the

time were being produced by dozens of similar

companies based in and around the Dudley area.

They were popular for many years until people

started buying harmonicas.

John Barnsley and Sons also

produced a range of cranes, until the firm began

to specialise in the production of lifting

equipment, starting with pulley blocks. By the

1950s the firm produced a variety of overhead

travelling cranes, which were very successful.

In the 1970s the firm produced explosion proof

equipment for North Sea oil rigs and the oil and

gas industries. Development of the cranes

continued and today the firm is a world leader

in the production of explosion proof cranes and

hoists. |

|

|

|

|

|

|

Coal, Iron

and Limestone Mines |

|

|

Ironworks |

|

|

Dudley's

Glass Makers |

|

|

Beans

Industries |

|

|

BSR |

|

|

N. Hingley and

Sons |

|

|

H. and T.

Danks and Edwin Danks |

|

|

Round Oak

Iron and Steel Works |

|

|

|

|

| Nail Making The

making of hand-made nails was a long established

industry that continued until the latter part of

the 19th century. Thanks to Richard Foley, who

set up a slitting mill at The Hyde, in Kinver to

produce iron rods for nailers, nail making

became a simple operation that could be carried

out by unskilled people. All they had to do was

to cut the rod to the correct length, point one

end, and make the head. It was one of the first

examples of mass production, because large

quantities of nails could be made simply and

quickly. |

|

Making nails in the nail shop

at the Black Country Living Museum. |

The nailers couldn't afford to buy the rods

themselves, they were advanced to them by the mills,

to where they returned the completed nails and were

paid for them. They were also given standard

allowances for waste. A bundle of rods weighed 60

pounds and was 4ft 6" long. The nails were

characterised according to the number produced from

a given weight of iron. Long thousand (1,200) nails

weighing 4 pounds, were known as four penny bundles.

Larger nails were called 100 work, and were

priced by the hundred. They were more profitable

than the smaller ones, as less work was required to

produce them, and less waste produced.

There were many types of nails including

brads, tacks,

spriggs, dog-eared frost nails, sheath nails, and

sparrables. |

| In 1852

around one quarter of the male and female

workers in Dudley and the surrounding area were

still producing nails, usually in a small

workshop at the back of their home. There was

some unrest in 1842 when nail makers’ wages were

reduced. Around 15,000 to 20,000 men met in the

town on the 25th April and kidnapped several of

the nail masters by force. The Riot Act was read

by the Mayor and troops were called-in from

Birmingham. The nail masters were only released

after promising to cancel the wage reduction. |

|

Another view of the

nail shop at the Black Country Living Museum. |

|

Samuel Lewis

and Company Limited

The business was

established at Netherton in about 1750, as a

nail manufacturer, specialising in horse and

mule shoe nails. The firm began to produce

pressings and forgings, particularly for farm

harrows, and handmade chain for specialised uses

such as horse gear. There were hundreds of

customers for nails, including the Admiralty,

the War Office and the India Office. They were

exported to many parts of the world.

M. and W. Grazebrook

The business, based at Netherton Iron Works,

Dudley, was founded in 1750. The firm mined coal

locally and originally had an old square blast

furnace. This was replaced by two blast furnaces, with a cold

blast, to produce iron. In 1817 the firm

purchased a Boulton and Watt blowing engine. There were three

partners, William Grazebrook, Michael Phillips

Grazebrook, and John Phillips Grazebrook. In

1865 William Grazebrook retired and the business

continued as before, with the same name, but run

by Michael and John Phillips Grazebrook.

It became a private limited company in 1914

and a public limited company in 1950. In about

1931, engineering, welding and foundry shops

were added to the factory. During World War Two

the firm helped develop 8,000lb. and 12,000lb.

block buster bombs.

In 1961 the business was acquired by N.

Hingley & Sons and was listed as a general heavy

engineering company and iron producer, with 250

employees, manufacturing all types of welded

fabrications, oil and chemical plant, rail tank

wagons, homogenous lead lined vessels and iron

castings. Also carrying out general machining. |

|

An advert from 1953. |

|

An advert from 1958. |

|

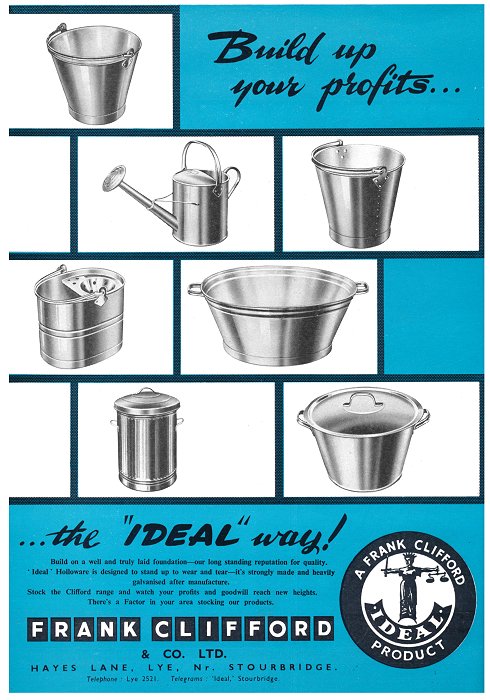

James

Griffin and Sons

Dudley once had a thriving

holloware industry, particularly thanks to the

products manufactured under the ‘Griffin’ name

by James Griffin & Sons of Withymore Works, in

Northfield Road, Netherton, alongside the canal.

The firm, founded in the late 18th century,

produced a wide range of products including

scythes, spades, forks, nails, spikes,

horseshoes, chains and buckets. James Griffin

died in 1818 and his son took over the running

of the business.

The firm was taken over by C. E. Swindell and

Company in 1856 and manufactured edge tools. The

business was later taken over by Joseph Russell

and taken over again in the 20th century by

chain maker Eliza Tinsley. The firm stopped

trading in 2005. |

|

An advert from 1849. |

|

An advert from 1958. |

|

J. G. Walker

& Son

J. G. Walker & Son, was

established in about 1814 by John Griffin

Walker, at Darby End (also known as Darby Hand),

Primrose Hill, Netherton. The firm produced

wrought iron nails, chain, high strength chain

cables and anchors. It began as a partnership

between Joseph Griffin Walker, William George

Griffin Walker and Henry Griffin Walker. In 1833

Henry Griffin Walker retired and the business

was then run by William and Joseph Walker.

Joseph Griffin Walker died

in 1864 and his grandson, W. H.

Walker Higgs, took his place in the business.

In 1866 William George Griffin Walker was

registered as a debtor by the Registrar of

Bankruptcy, but was allowed to carry on trading

in order to pay off the creditors. In 1881

William George Griffin Walker, died

and the business was then run by

W. H. Walker Higgs.

In the early 1900s the firm specialised in

crane and mining chains, ship chains and cables.

Most of the chain was exported to Australia, New

Zealand and South Africa. |

|

An advert from 1891. |

|

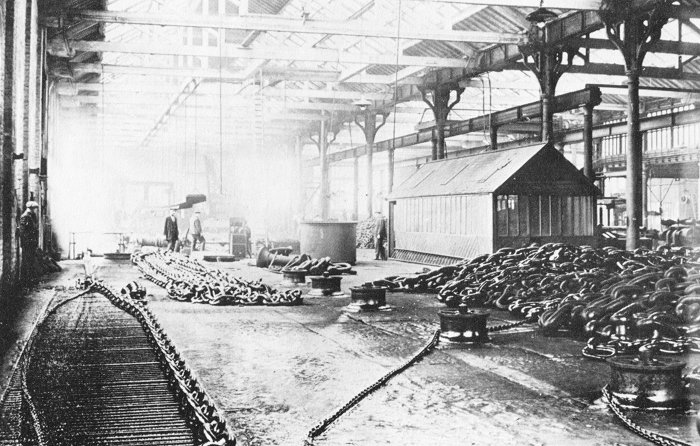

Lloyds Proving

House, Netherton

Lloyds Proving House was situated in Cradley Road,

Netherton, alongside the canal.

In 1865

it received a license from the Board of Trade for the

testing of chain cables, chains, and anchors. The first

superintendent was Mr. S. Tregenner.

In

1894, Henry Green was appointed as

superintendent and more powerful machinery was installed

to meet the requirements of various Acts of Parliament,

and of the rapid developments that were taking place in

the manufacture of chain, cable, and anchors.

It became

the largest and most complete proving house in the

country. In 1900 the establishment became part of

Lloyd's British Testing Company.

Henry Green remained as

superintendent until his retirement in 1936 and was

responsible for many reports on the testing of anchor

chains and cables. In 1926 he visited continental

testing houses to study their facilities for examining

chains and drew up specifications for many of the

testing machines installed at other testing houses. The

Netherton Proving House closed in 1990. |

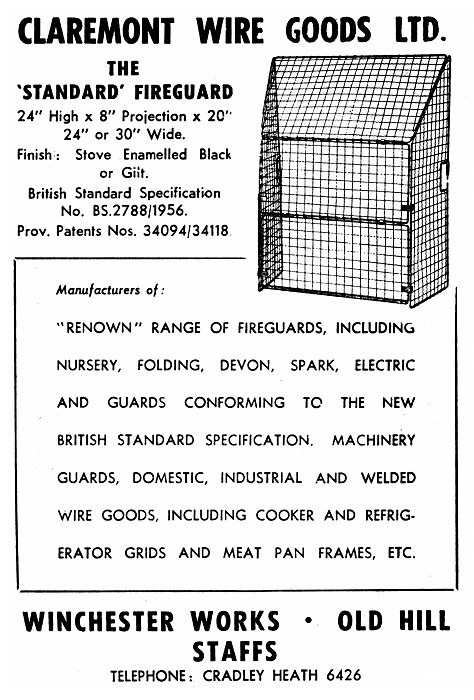

An advert from 1958. |

|

Lloyds Proving House

at Netherton. From an old postcard. |

|

Atlas Tube

Works, Netherton

Atlas Tube Works in Netherton

was established in 1858 by Henry Parkes Skidmore,

born in January, 1831. In the first part of the 19th

century there was a great demand for wrought iron

tubes to carry town gas from local gasworks to all

parts of the area. This became possible thanks to

Cornelius Whitehouse of Wednesbury, who patented a

greatly improved method of manufacturing tubes in

1825.

Atlas Tube Works was

established to produce tubes using Cornelius

Whitehouse’s patented method. Around 140 men were

employed, making the tubes at the factory using some

of the best and most up-to-date machinery. Strip

iron for making the tubes was purchased locally as

was bar iron, used to make the sockets and fittings.

Around 60 to 80 tons of tubes and fittings were

produced each week, as well as a large number of

garden seats that had supports made from tubing.

The firm also produced wrought

iron welded coils for boilers etc. and the patented

Atlas hot water coil stove that formed the basis of

an early central heating system. There was a tramway

at the factory to move things around the works and

onto the adjacent canal wharf.

Henry Parkes Skidmore married

Blanche Jones in 1857 and they lived at Hill House

in Netherton. He died of diphtheria on the 9th

October, 1861. His son, Henry Parkes Skidmore, born

in 1860 took over the business in partnership with

Thomas Jones. In the 1881 census he is listed as

living in Church Road, Netherton. In 1883 he bought

Stonehouse Farm at Fockbury near Bromsgrove and by

1891 had retired to Austin's Close, Harberton in

Devon. Henry Parkes Skidmore junior, died in Devon

on the 9th March, 1897 at the age of 36. |

|

An advert from 1876. |

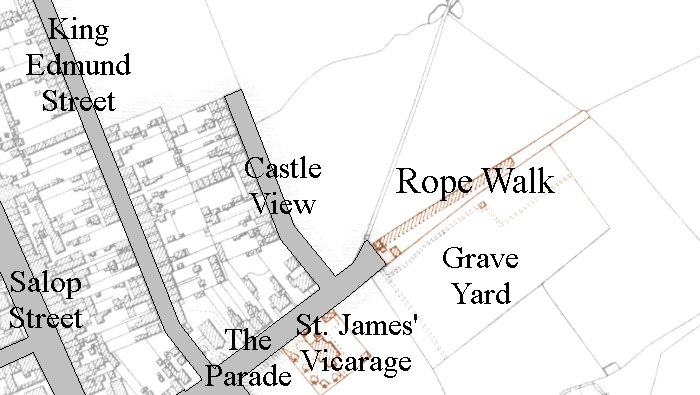

| W. & S. Gorton W. & S. Gorton of Eve Hill had

a rope walk beside the grave yard belonging to St.

James' Church. The business was founded in 1788 and

produced a wide range of ropes, including boat

lines, using the 'Samson' brand name. On the rope

walk, fibres of mainly hemp were twisted into rope.

There was a similar business at Holly Hall, run by

Benjamin Whitehouse. |

|

The location of W. & S.

Gorton, Eve Hill. |

|

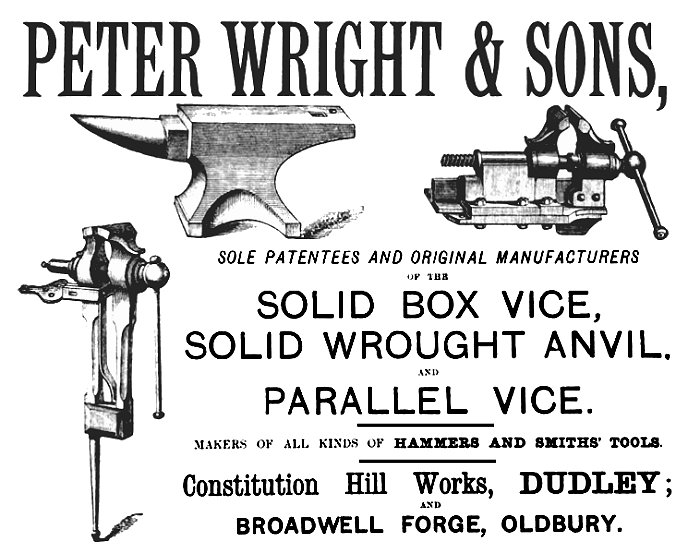

Peter Wright

& Sons

Peter Wright started

producing vices and anvils in the early 19th

century in Black Acre Road, where Shedden Street

now stands. Peter Wright was

born in Dudley on the 15th March, 1803 and

started in business in the trade that had been

carried out by his family in the same place for

over 100 years.

He made many improvements in

the manufacturing of anvils and vices and became

senior partner in Peter Wright and Sons, of

Dudley and Oldbury. In 1848 he invented and made

the machinery for cutting the internal screws of

vice-boxes out of solid iron, making the

‘solid box vice,’ and in 1852 he invented the

'solid anvil', the first to be forged in one

piece by means of dies and by turning it

frequently under the hammer during forging.

Over 11,000 of them were sent to America

alone.

In 1862 he invented the parallel vice, and an

improved railway wheel. He died on the 28th

August, 1874 at the age of 71. The

firm was acquired by Isaac Nash in 1904 to 1905

and was later a part of the Spear & Jackson

Group. |

|

An advert from 1890. |

|

An advert from

1855. |

|

An advert from

1855. |

|

An advert from 1855. |

An advert from 1896.

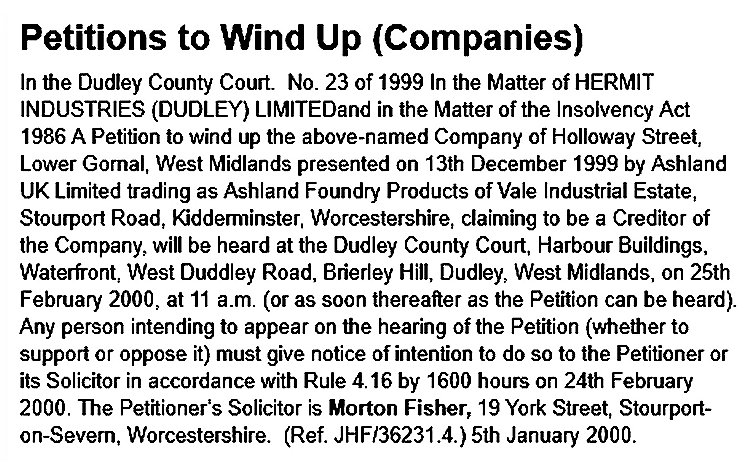

Hermit Industries.

| The firm was established

in 1947 at 21 Hermit Street,

Upper Gornal. In February

1964 a fire broke out in the

pattern shop, which was

badly damaged.

The factory closed in

about 1970 and moved to a

new site in Holloway Street,

Lower Gornal, adjacent to

the Fibre Form Company. |

An

advert from 1960. |

An advert from

1985.

The factory produced both ferrous and

non-ferrous castings for the engineering

industry and had two coke fired cupola

furnaces with tall chimneys, which stood

out on the hillside.

The factory in

1990.

Another view of

the factory in 1990.

Residents who lived in the nearby

housing estate were annoyed by the smell

and the dust that was emitted from the

prominent fifty foot high chimneys. The

factory closed in 1992 because it was

unable to meet the legal pollution

requirements and an excessive amount of

foreign competition. Eighteen people

were made redundant and the company went

into voluntary liquidation in February

2000.

From the Gazette.

The factory was demolished, as was

the adjacent Fibre Form works and the

area is now a large housing estate.

|

|

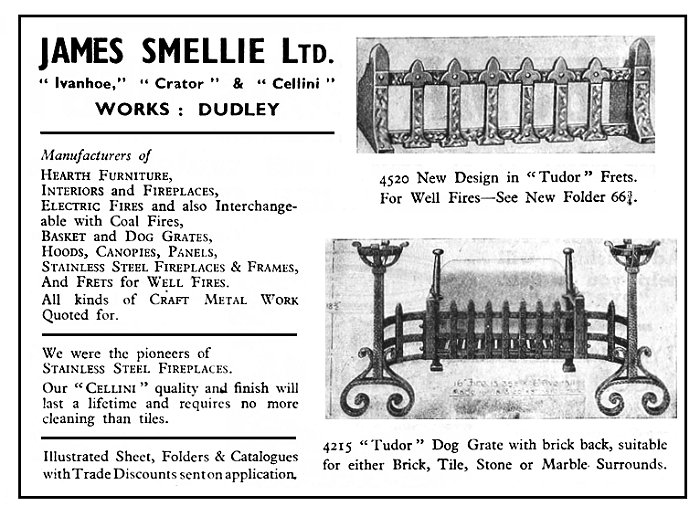

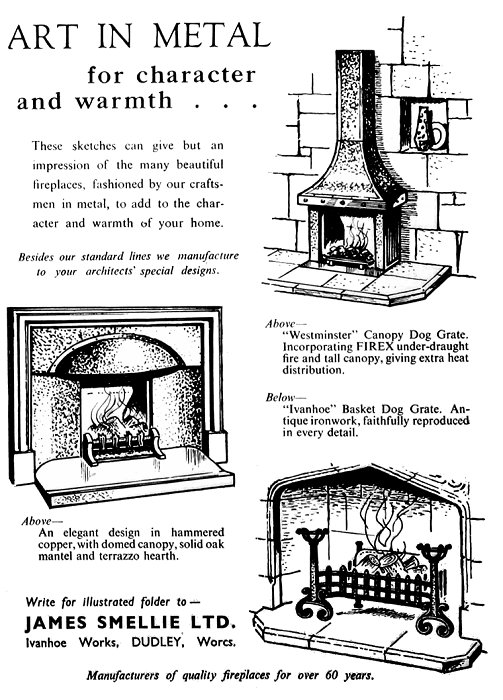

James

Smellie Limited

James Smellie was born on a

farm in Ayrshire on the 31st May

1861. In 1878 after going to school at Hutton

Hall Academy, he served an apprenticeship as an

ironmonger in Dumfries and continued his

education by attending classes in several

subjects including Mathematics, Chemistry and

Geology.

In 1882 he

worked for a while in an iron monger’s shop in

London, followed by two years in Penrith, before

moving to Birmingham in 1887, where he became a

representative for a manufacturer that

specialised in steel fire irons and burnished

steel and ormolu fenders.

He purchased a partnership

with a manufacturer of cheap iron and brass rail

fenders in Dudley, in 1893 and they began to

produce a wide range of brass, copper, pierced

and forged hearth suites, grates and fire

places.

He travelled throughout the

country promoting the company’s products,

opening over 2,000 new accounts. Thanks to his

efforts they became the largest manufacturer of

hearth suites in the country.

In 1901 James was elected as a member of

Dudley School Board and became a local

councillor in 1903, representing the St Thomas

Ward.

On the 8th January, 1904 the

partnership was dissolved on friendly terms, and

James purchased the works, the property, the

patterns etc. and continued to run the business

under his own name.

The firm was based at

Ivanhoe, Cellini and Crator Works, Oxford

Street, Dudley. The business thrived and in 1906

became a private limited company with 30,000

ordinary one pound shares, all owned by members

of his family. Products included fenders, hearth

suites, dog grates, coal boxes, lamps, fire

screens and the polished steel ‘Ivanhoe’

fireplace, one of which was supplied to Princess

Mary. Ivanhoe fireplaces were then supplied to

many of the old historical castles as well as

wealthier households and the largest hotels in

the country. The firm also supplied all of the

brass tomb railing for the Sultan of Morocco’s

grave. |

|

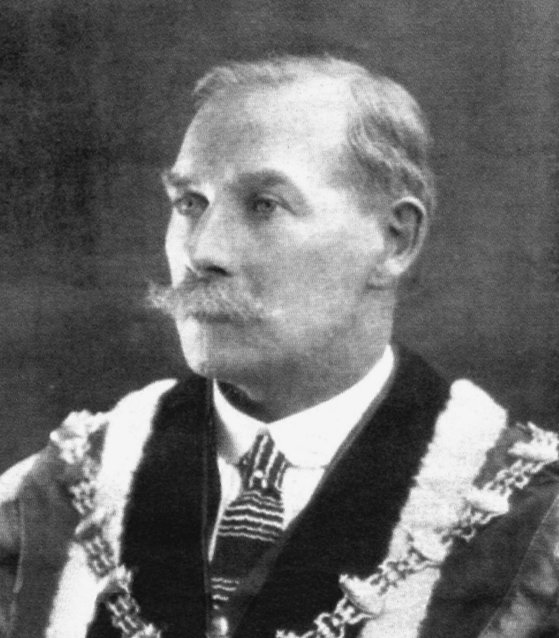

James Smellie in his

mayoral robe. |

In 1909 James became Chairman of the

Elementary, Higher and Technical Education

committees and became a magistrate in 1917. In

1924 he became an alderman and was Mayor of

Dudley from 1924 until 1926.

He lived at Comberton House, Kidderminster.

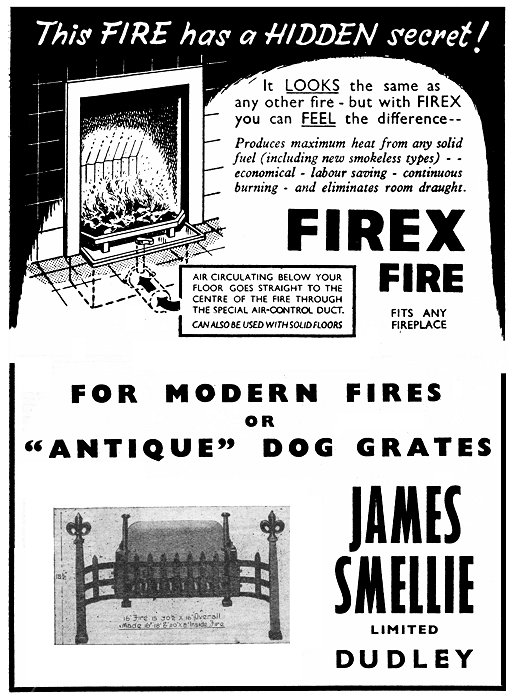

By the mid 1930s, James Smellie Limited also

produced coal and electric fires. The firm still

exists and is based at Halesowen.

|

|

An advert from 1938. |

|

An advert from 1958. |

|

An advert from 1961. |

|

Dudley also had a number of

leather producers.

Hillmans, founded in 1852,

in Newhall Street, supplied leather to

cobblers. They then moved to 14 Hall Street,

a 3 storey building with a shop at the

front.

By 1870 they

produced whole hides, morocco leather, goats,

fancy leathers, belts, cases, oil seals, special

types of industrial leathers including oil butts

and stale butts for collieries, footballs,

tennis equipment and sports gear.

The firm was known as J. &

H. Hillman of Castle Leather Works in the 1890s,

and later as J. and A. Hillman.

They began to manufacture

industrial belting, which was very popular and

moved to larger premises on the corner of

Trindle Road and Porter Street.

In 1906 they took over the

neighbouring tannery of J. R. Tilley.

The firm later specialised

in handbags,

motor hides, belting and harness leather. In

1958 there was a fire in part of the

works. |

An advert from 1958. |

|

John Nayler & Son of Castle Belting Works,

Dudley, made leather belting.

John Douglas, Son and Company of Trindle Works,

made a range of products in 1922 including footballs,

golf bags, leggings and gaiters, purses and

wallets, fancy goods, fishing bags, game bags

and camera cases.

In 1947, Trindle Works was run

by

John Douglas, Sons and Company.

Their product

range included high

class fancy leather goods, handbags, wallets,

notecases, travel bags, document cases, attaché

cases, suit cases and golf bags.

|

|

|

|

|

|

Return to the

20th Century |

|

Return to

the contents |

|

Proceed to

World War One |

|