| A Brief History

Joshua Bigwood & Son Ltd. were an engineering

company based in Wednesfield Road, Wolverhampton.

The company, which was founded in 1874 produced a

wide range of machinery and heating equipment. It became a

public company in 1937 and initially provided machinery for

local industries.

One of the company's early products is

this drain channel in Gordon Street, Wolverhampton.

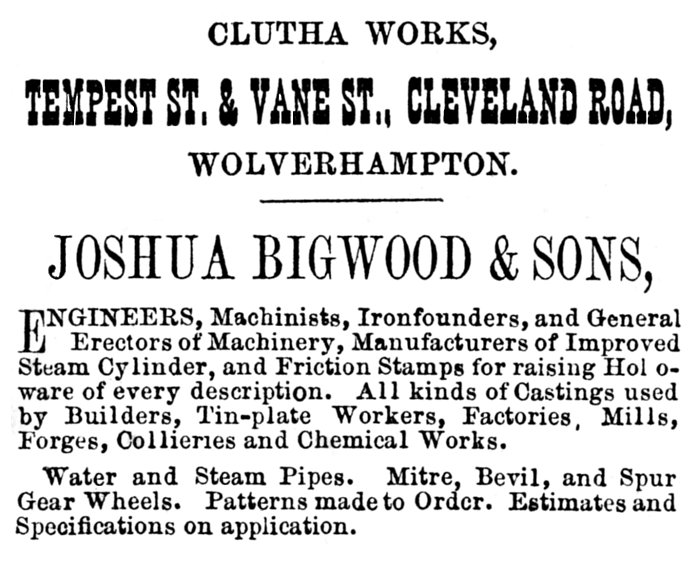

An advert from the 1880s for the original

factory.

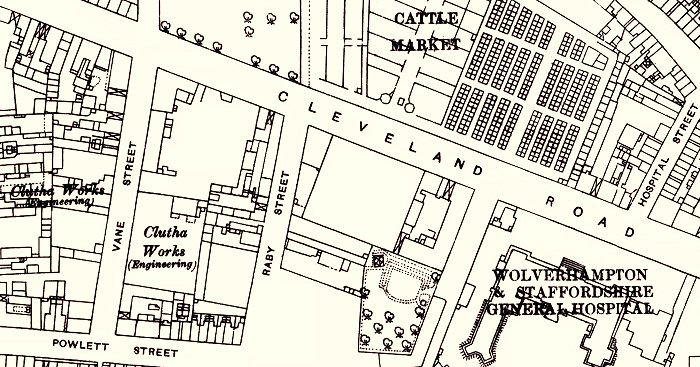

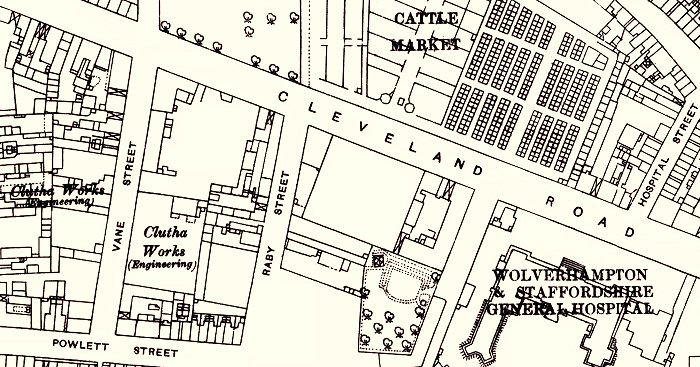

The location of Clutha Works.

In the 1930s the company moved to the

Wednesfield Road site and expanded to form The Bigwood

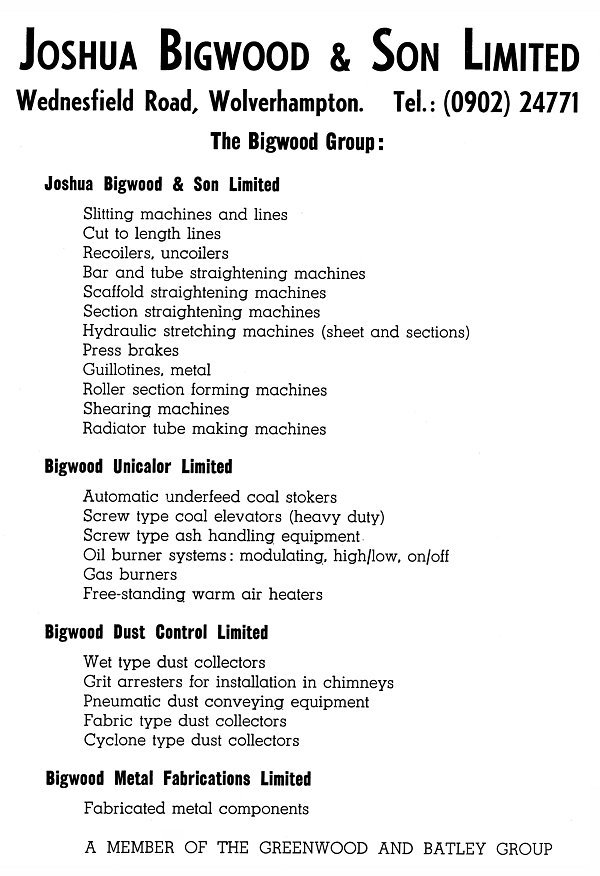

Group, which consisted of five divisions:

The Metal Forming Division produced

straightening machines for tube, bar and section. Oil, sheet and

plate processing machines, roll forming

machines, plate levellers, slitting lines, three or four roll

bending machines, cut-to-length lines, press brakes,

guillotines, shearing machines and stretch-levellers.

The Radiator Division manufactured a complete

range of equipment for motor vehicle radiator production , which

was exported to almost every country.

The Heating Division operated under the trade

name, Unicalor and was Britain's leading manufacturer of

automatic coal stokers. The company supplied stokers for the

heating of public buildings, schools, hospitals and factories,

both at home and abroad. Other equipment manufactured by this

Division included coal elevators, ash crushers, ash extraction

units, and burners for anthracite, turf and other fuels.

The Dust Control Division specialised in

equipment for the control, collection and suppression of dust

and treatment of trade effluent. In the 1960s it was known as

'The Traughber Filter Company Limited' and was later called

'Bigwood Dust Control Limited'. The company’s products included

wet type dust collectors, grit arresters for installation in

chimneys, pneumatic dust conveying equipment, fabric dust

collectors and cyclone type dust collectors.

The Fabrication Division supplied fabrications

to the parent company and to the trade in general. In the 1960s

the division traded as 'The Butro Jig & Engineering Company

Limited' and in the 1970s was called 'Bigwood Metal Fabrications

Limited'. As well as metal fabrications the company produced

jigs, assembly fixtures, press tools and carried out all kinds

of precision engineering work.

|

A very solidly built Bigwood

wood-turning lathe. Courtesy of Tim Roper. |

|

The manufacturer's plate on

the lathe above. Courtesy of Tim Roper. |

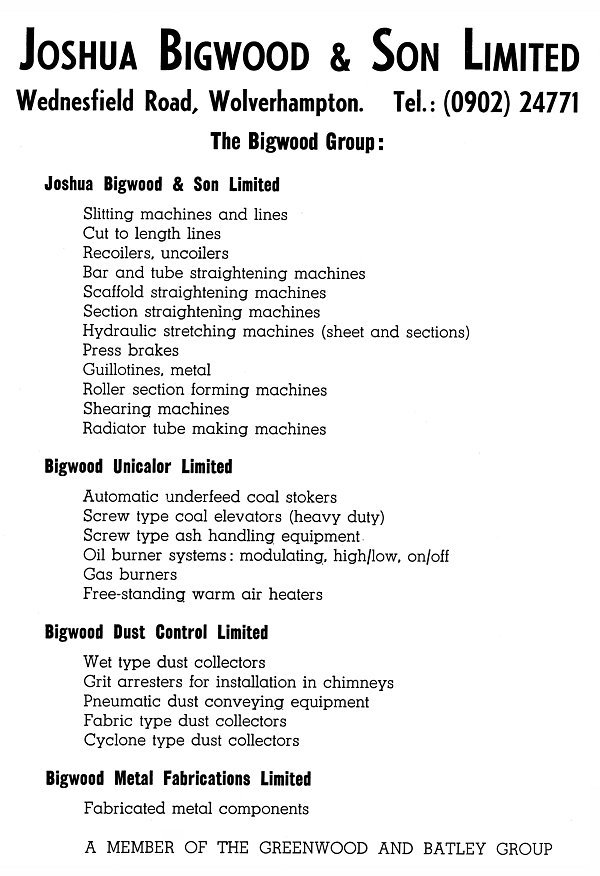

An advert from 1970.

The group had area offices in Manchester,

London, Glasgow and Bristol. The group’s managing director was

John Byam-Grounds who came to Wolverhampton after working for

the Alvis Car Company in Coventry and B. & M. Massey of

Manchester, who made drop hammers and presses. John was an

active mountaineer and a member of the Alpine Club.

The museum’s engineering hall has several of

the company’s products on display:

|