|

The Owen Organisation is always thought of as a

Darlaston firm, and rightly so. The Organisation's base

at Darlaston, although large in manufacturing terms, is

only a small part of the story, which covers much of

this country, and spreads across other continents.

By the 1960s the Owen Organisation employed

around 15,000 people, in eighty eight companies, operating on

five continents, and became one of the country's largest

private companies.

The Organisation manufactured products and parts for

almost every industry, and manufactured, or supplied,

almost everything for use in the home.

The Structural Department supplied the structural

steelwork for many of the country's iconic buildings,

and even produced pre-fabricated houses for a time,

after the Second World War.

There can't have been many British companies that

operated on the same scale as the Owen Organisation, it

was unique. |

A map produced by Rubery Owen,

showing the location of the UK subsidiary companies in

1947. |

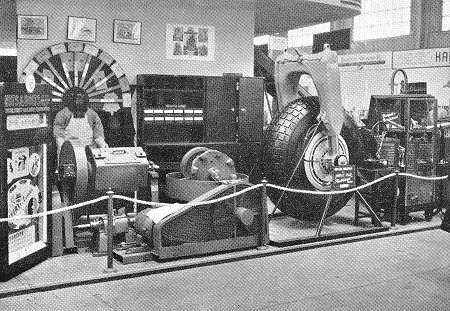

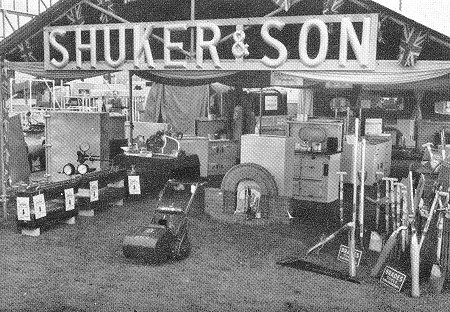

| An impression of the Organisation's vast range of

products, can be got by looking at the photographs

below, which show parts of the company's display at the

British Industries Fair in May 1947, and in 1949, at Castle

Bromwich. |

|

Products on display, on this

part of the stand, include nuts and bolts, pressings,

axles, wash basins, shelving and storage units, and

parts for machinery.

From the summer 1947

edition of the staff magazine "Pyramid". |

| This part of the display

includes lathes, machinery, component parts, and

shelving.

From the summer 1947

edition of the staff magazine "Pyramid". |

|

|

Another part of the display

includes an aircraft wheel and part of an undercarriage,

machinery, nuts and bolts, and storage units.

From the summer 1947

edition of the staff magazine "Pyramid". |

| Another display at the same

event was provided by another member of the

Organisation, Shuker & Son. It includes garden tools, a

lawnmower, kitchen units, and mirrors.

From the summer 1947

edition of the staff magazine "Pyramid". |

|

|

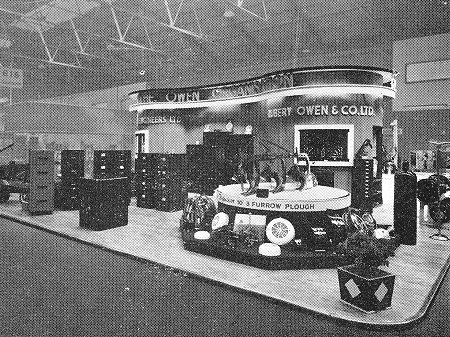

The Organisation also had stands at the 1949 British

Industries Fair, also held at Castle Bromwich. This

stand includes a 3 furrow plough, fans, filing cabinets,

storage units, and what appears to be motor wheels.

From the summer 1949 edition of the

staff magazine "Goodwill". |

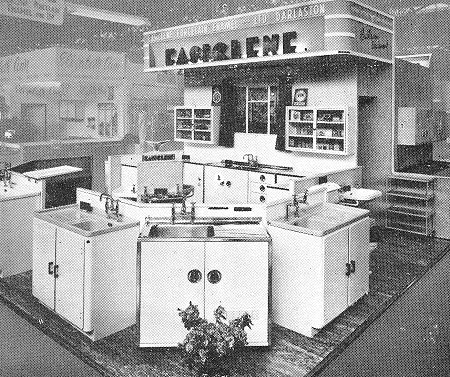

| The Easiclene display includes

kitchen units, sinks, and sink units.

From the summer 1949 edition of the

staff magazine "Goodwill". |

|

|

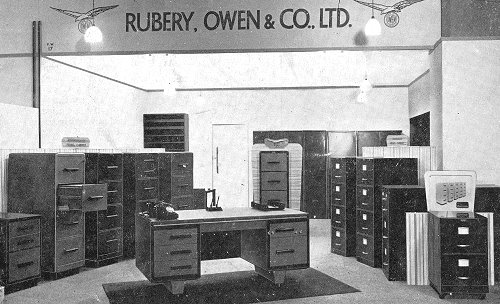

The Organisation's stand at

the Business Efficiency Exhibition at Olympia in October

1949 showing some of the company's office furniture.

From the spring 1950 edition of the

staff magazine "Goodwill". |

From Histories of Famous Firms - Midlands Survey part one,

1960. |

One of the organisation's companies, which became

well-known for its specialised products, was Invicta

Electrodes Limited in Bilston Lane, Willenhall, on a

corner of the main Rubery Owen site.

The firm produced a wide range of electrodes suitable

for welding mild steel, medium high tensile cast iron, steel

reinforcing, and stainless steel.

The electrodes were marketed

using the trade name "Wey", including "Speedway" and "Deepway",

and were produced on machinery built by companies within the

Owen organisation.

The factory was extended during the Second

World War to enable the firm to fulfil a number of Government

contracts which resulted in the production of millions of feet

of electrodes.

The factory had all of the latest facilities

including chemical and mechanical laboratories, X-ray machines,

and microscopy, to ensure that the products were of the highest

quality.

|

| |

|

|

| |

|

Read about some of the companies: |

|

|

C. & L. Hill Limited,

Willenhall |

|

|

Bentley

Hall Brick Company Limited, Bentley, Walsall |

|

|

Chains

Limited, Moxley |

|

|

Nuts &

Bolts (Darlaston) Limited |

|

|

Charles

Clark & Son Limited, Wolverhampton and Shrewsbury |

|

|

The

Brooke Tool Manufacturing Company Limited, Birmingham |

|

|

A. G.

Sutherland Limited, Birmingham |

|

|

Salopian

Engineers Limited, Prees, Shropshire. |

|

|

Motor

Panels (Coventry) Limited |

|

|

Rubery,

Owen & Company Limited, Wrexham |

|

|

Rogers &

Jackson Limited, Wrexham |

|

|

Electro-Hydraulics Limited, Warrington |

|

|

Rubery

Owen (Warrington) Limited |

|

|

Camelinat

and Company Limited, Birmingham |

|

|

|

|

|

Courtesy of Christine and

John Ashmore. |

|

It is often forgotten that

Darlaston's wonderful ironmongers in King Street was

part of the Owen Organisation.

J. W. Baker & Company Limited, in

King Street, in about 1965.

Courtesy of Bill Beddow. |

|

|

Rubery, Owen & Company Limited, Coventry

A branch factory was established in

1936, in Paynes Lane, Coventry, for the production of

pressed and fabricated assemblies that were used to

assist production at Darlaston, and also supplied to

industry in general.

During the Second World war, the

factory produced large numbers of pressings, and

essential war equipment, including floats, buoys, mine

containers, steel helmets, fuel tanks and Soyer Stoves

for field kitchens.

After the war, many of the small

components and assemblies produced at the factory were

for the local vehicle manufacturers. The company

specialised in general sheet metal working, especially

in limited quantities, particularly fuel tanks for

commercial vehicles. Orders for larger quantities were

dealt with at the Darlaston factory. |

|

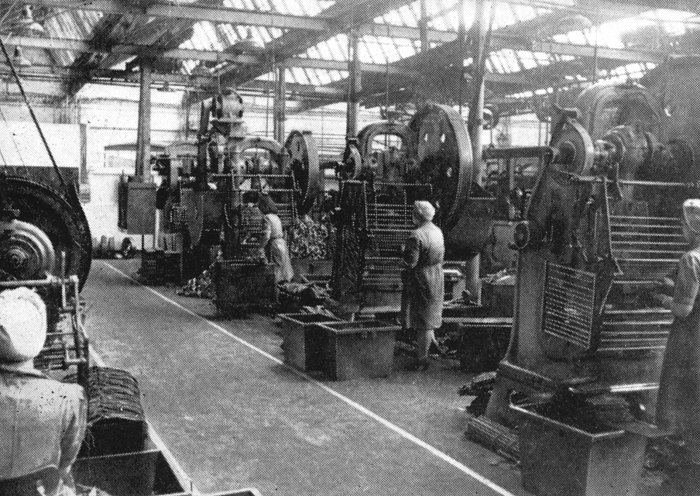

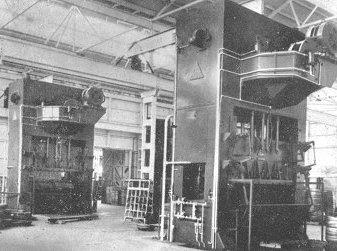

Part of the press shop at

Coventry. |

|

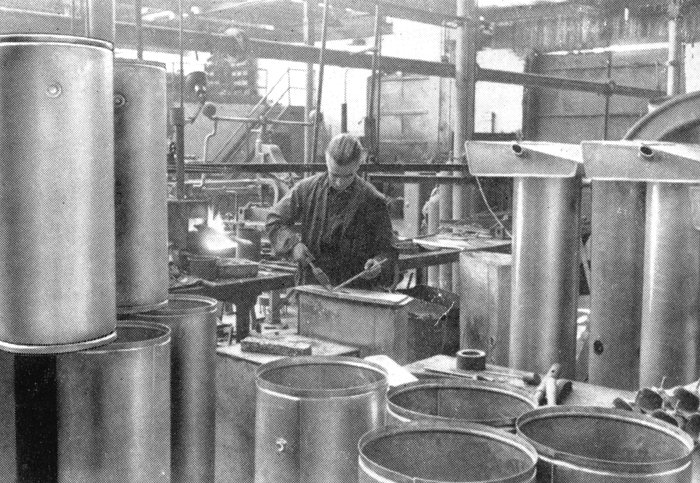

Assembling pressed ends of fuel

tanks for commercial vehicles, at the Coventry factory. |

|

Denfords Engineering Company Limited, Halifax

Denfords Engineering Company

Limited, began in a small way in 1931, manufacturing

jigs and fixtures. The business flourished, and larger

premises were soon needed.

In the late 1930s, the company

began to manufacture a range of precision jigs and

fixtures, both for general industry, and particularly

for the Aircraft Industry. At the same time, development

of comparator gauges began, which after Government

approval, were

produced in large quantities.

A new factory was established at

Box Trees Mill, Wheatley, Halifax, where sine tables,

sine centres, straight edges and other equipment was

added to the product range.

After the war new products were

added, including plain 3 inch bench lathes, and a new

and improved type of light screw cutting lathe, aimed at

general engineering industries, research laboratories,

and education authorities. A new model, the 'Box-Ford'

4½ inch screw cutting lathe was introduced, which sold

extremely well. They were sold in the UK and exported to New Zealand, South Africa, Kenya, Norway,

Holland, Egypt and Canada.

The firm became a member of the

Owen Group in 1949, due to its association with T. S.

Harrison. |

|

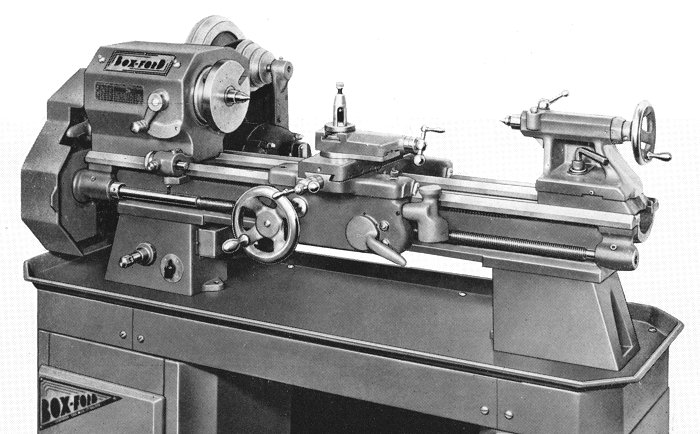

A 'Box-Ford' 4½ inch screw cutting lathe. |

|

Australia In 1946 work began on equipping a factory in South

Australia to house a subsidiary of Rubery, Owen &

Company, Limited. The factory was in part of

the Finsbury gun ammunition factory, covering over

200,000 square feet.

The new company would be called Rubery, Owen

& Company (Australia), Limited and would produce

automotive components such as road wheels, chassis

frames, axle casings and motor pressings, for the large

Australian car manufacturers in Adelaide and elsewhere,

including General Motors, Holdens, and Chrysler.

Mr.

Hambleton, Managing Director of the Australian branch,

recruited a lot of skilled personnel in the UK to work

in the factory, mainly from the London area. Other Australian subsidiaries included Rubery Owen & Kemsley Pty Limited

in Adelaide, who supplied components to the Australian

car manufacturers, and to the agricultural industry, and

two members of the

Conveyancer Group,

Conveyancer Pty Limited (Australia), and Paul-Walden Pty Limited (Australia). |

|

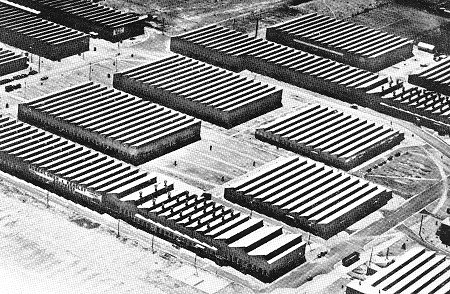

Part of the 30 acre Finsbury

factory site, occupied by 13 companies. Rubery Owen had

the three buildings in the foreground.

From the summer 1948 edition of the

staff magazine "Goodwill". |

|

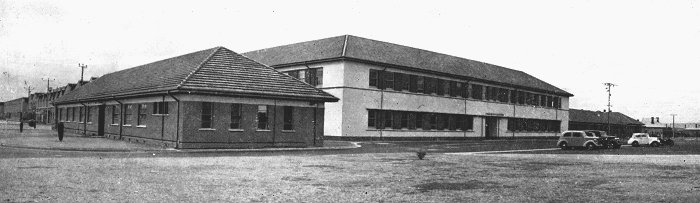

Part of the Finsbury Factory.

From the Christmas 1947 edition of the

staff magazine "Yuletide". |

|

The Finsbury staff in 1948.

From the summer 1948 edition of the

staff magazine "Goodwill". |

|

Rubery, Owen & Kemsley (Pty.) Ltd., Australia

Rubery, Owen & Kemsley

Proprietary Limited was incorporated in Adelaide in

the State of South Australia in November, 1946, to

manufacture automotive components. The factory with

a floor area of 120,000 square feet, was previously

part of the Finsbury Ammunition Factory, situated 7

miles from Adelaide.

The new company was fully

equipped with a modern tool room and machining plant

that produced tools and jigs. There was also an

extensive press plant with single and double-action

type presses, of up to 750 tons capacity, and a

processing and finishing plant. The products

consisted of components for the automotive and

agricultural industries.

The rim and wheel section

produced thousands of wheels for leading makes of

vehicles, including Chrysler, and General Motor-Holdens.

The press shop produced pressings for trucks and

tractors, including valve housings, manifold heat

shields, water header covers, chassis members and

bumper bars. There was also a section that

specialised in the general assembly of imported

commercial trucks, cab-bodies, and saloon cars. |

|

|

Two external views of the

factory. |

|

|

|

|

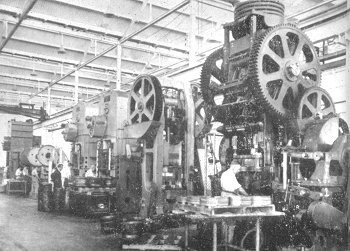

Two interior views of the

factory. |

|

| In the 1970s and 1980s many of the subsidiary

companies were either sold or ceased to operate. In 1993

Rubery Owen Holdings Limited decided to move away from

manufacturing, and so any remaining manufacturing

subsidiaries were sold. It now concentrates on property,

investment, and a small number of independent operating

subsidiaries. |

|

|

|

Return to

Sports & Leisure |

|

Return to

the contents |

|